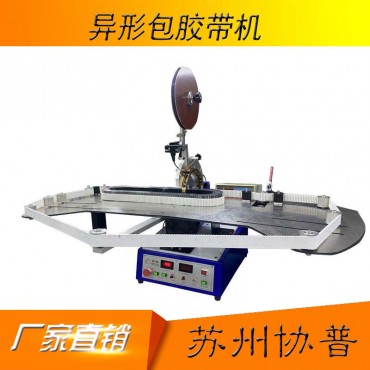

R-Core transformer winding machin sp-r2000

- Brand: 协普/REPOSAL

- Product Code: sp-r2000

- Availability: In Stock

- Ex Tax: 登录以查看价格

R-Core transformer winding machine has a wide range of application, high precision and convenient control, especially the wide range of wire diameter and coil size (you can set the speed, number of turns, width, wire diameter and other parameters, see instructions for details) and are widely received by customers Agree.

Features of R Core transformer winding machine

1.R Core transformer winding machine special controller, high precision, stable and reliable, easy to operate, computer (single chip microcomputer) control, full key operation, working state digital display.

2. 1000 sets of process data can be stored and called, and it has the function of button and foot start and stop, and the speed can be increased and decreased during the winding process.

3. Handle built-in start-stop switch, which can improve efficiency, especially convenient for debugging.

4. The configuration of a first-line brand laser amplifier, long life, high precision, low failure rate, stable and reliable counting, laser amplifier installation structure optimization, can be far away from the coil skeleton end face accurate and reliable detection of the number of turns, from the root to solve the probe collision roller and skeleton movement brought about by the count unreliable problem.

5. The press wheel adopts the step bearing design, which can effectively control the axial movement of the skeleton in the rotation process.

R-Core transformer winding machine parameters:

1. Controller: precision winding controller

2. Wiring structure: built-in double-axis precision wiring rod.

4. Clamping mechanism: PU pressure wheel with high precision inlaid bearing. High roundness, long life.

5. Tension control: standard mechanical tensioner, automatic stress relief function.

6. Wire diameter range (mm) : 0.05-1.8mm

7. Rotating diameter of machining coil :120mm

8. Maximum speed (rpm) : 3000 RPM

9. Number of winding spool: 1

10. Spindle motor: 0.6KW precision static single DC brushless motor.

11. Row wound motor: improved precision stepping motor

12. Line width (mm) : 140

13. Power supply 220V/50HZ

14. Size and weight :70X60X50CM 40KG