Flying fork winding machine

Suzhou REPOSAL® Electronic Machinery Equipment Co., Ltd. specializes in providing the following machines: winding machines, flying fork winding machines, transformer winding machines, open-core transformer winding machines, rotor winding machines, single-axis flying fork winding machines, parallel flying fork winding machines, semi-circular transformers, winding machines for cooling fan coils, winding machines for blower coils, toy motor winding machines, and micro motor rotor winding machines.

The REPOSAL® fork winding machine is a winding machine used for winding coils for motors, inductors, clamp-on ammeters, transformers, etc.

1.Working principle :

The flying fork winding machine mainly achieves winding work through the high-speed rotation of the flying fork assembly. The flying fork assembly is installed on the rotating turntable, which is driven to rotate by motor and other drive components. When the flying fork rotates, the copper wire or other wire materials are guided to the flying fork by a specific feeding mechanism. As the flying fork rotates, the wire materials are wound around the workpiece such as the stator core according to the predetermined pattern, thus completing the winding of the coil.

2. Structure Composition:

Fork Components: These are the core components of the flying fork winding machine, typically consisting of a fork stand, a wire outlet adjustment bracket, and other parts. The fork stand is used to support and fix the flying fork, while the wire outlet adjustment bracket can adjust the position and angle of the wire outlet to meet different winding requirements.

Drive System: This includes the drive component that rotates the turntable with flying forks, as well as the motor that drives other parts. The drive system provides power for the rotation of the flying forks and the movement and rotation of other parts, ensuring a smooth winding process.

The winding mechanism: This mechanism ensures that the wire is wound in a predetermined pattern during winding, resulting in a neat and compact coil. The winding mechanism typically consists of a worm gear, a winding motor, and a cam, among other components.

The feed-in mechanism: responsible for introducing the copper wire or other wire materials into the winding area. The feed-in mechanism usually includes tensioning components, pulling components, and several guiding wheels, etc. The tensioning components can ensure the flatness of the copper wire, while the pulling components are used to control the tension of the wire materials.

Control System: The REPOSAL®

flying forks winding machine controller is responsible for controlling and monitoring the entire winding process. It can set winding speed, turns, and winding pattern, and can also monitor the operating status of the winding machine in real time to help solve problems in a timely manner. At the same time, it uses the most widely used CNC control panel in the market, making the control panel of the controller clear and organized, especially friendly to those who have experience with CNC winding machines, as it is easy to understand.

3. Application fields:

The motor manufacturing industry: widely used in the winding of stator and rotor coils of various motors, such as brushless motors and brush motors. For example, in the production of coils for drones, electric vehicles, and cooling fans, the flying fork winding machine can efficiently and accurately complete the winding work, providing assurance for the performance of the motor.

Inductor Manufacturing Industry: Used for winding various types of inductor coils, such as common-mode inductors and differential-mode inductors. A flying spindle winding machine can precisely control the number of turns, wire diameter, and winding method of the coil according to the design requirements of the inductor, thus meeting the performance requirements of the inductor.

Other Electronic Equipment Manufacturing Industries: In some electronic equipment production processes that require winding coils, such as transformers and relays, the flying spindle winding machine also plays an important role. After being custom-designed, it can also be used for continuous winding on flexible materials. ,

4. Advantages and Features:

High winding efficiency: The high-speed rotation of the flying fork can quickly complete the winding process, greatly improving production efficiency. Compared with traditional manual winding, the winding speed of the flying fork winding machine can be increased by several times or even tens of times.

High winding precision: Through precise control systems and winding mechanisms, the winding precision of the coil can be guaranteed, making the number of turns, wire diameter, and spacing of the coil meet the design requirements, thereby improving the quality of the product.

It has a wide range of applications: it can be used for winding different types and sizes of workpieces, and it can also perform winding work well for workpieces with complex shapes and high winding requirements.

High degree of automation: it can achieve automated winding, reducing the number of manual operation steps and lowering the labor intensity, while also improving the safety and stability of production.

High safety: During operation, the forking components of the wire winding machine are usually exposed to positions that can be touched by humans. The COP flywheel winding machine is equipped with a safety guard to ensure safe operation.

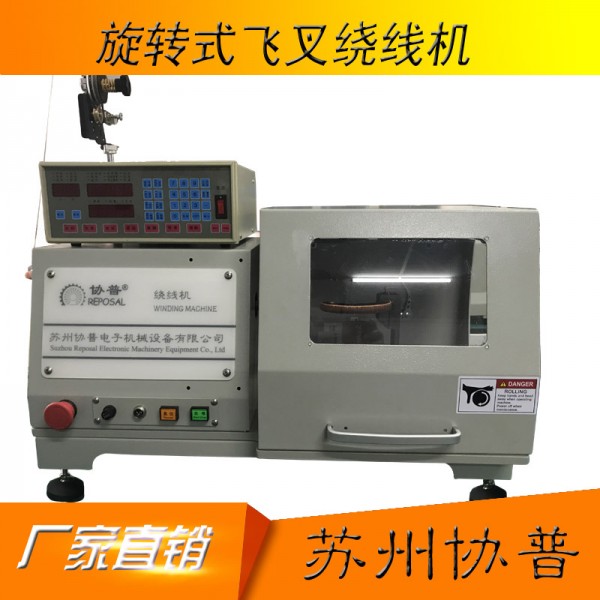

Flying fork winding machine-rotary sp-d102fc

Applicable scope of rotary flying fork winding machine Xiepu Rotary Flying Fork Winding Machine is mainly for the production and development of transformer wind..

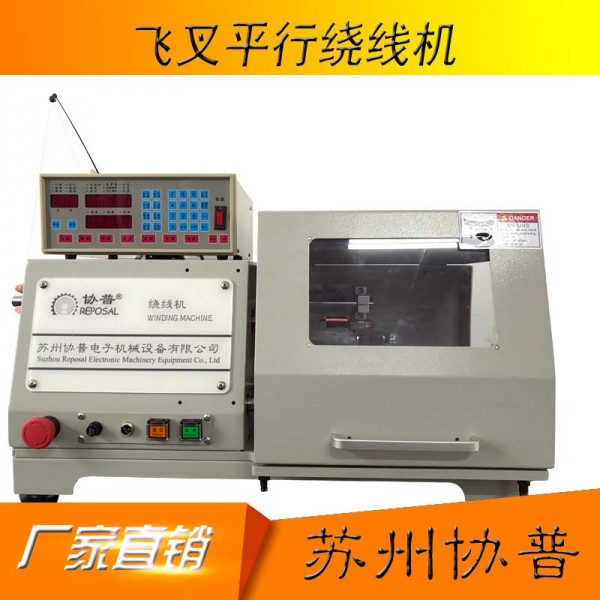

Parallel fly fork winding machine

Parallel fly fork winding machine (Reference video) REPOSAL parallel flying fork winding machine is mainly for the production and development..