REPOSAL® winding machine releases special winding machine for frequency divider inductors

REPOSAL® winding machine releases special winding machine for frequency divider inductors

In daily life, have you ever noticed more than one horn on your car? And more expensive cars have more horns. According to normal people's thinking, the car as long as there is a horn can emit sound signals on the line, more horn is why? The reason is very simple, for example, the turn signal and the warning horn are completely different, the sound frequency is different, and the sound range of the speakers used for high and low is naturally different. A single speaker cannot play a full frequency sound, and a sound may require a combination of multiple channels of sound to achieve a clear cue.

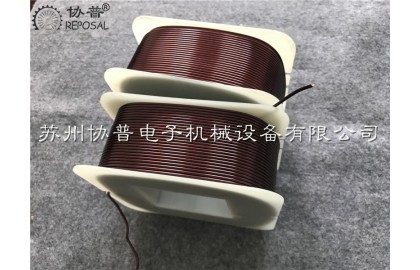

Therefore, in order to make each speaker emit audio suitable for it, it is necessary to use a tool such as a frequency divider. In simple words, the frequency divider is a filter circuit composed of a capacitor and a frequency divider inductor coil wound by the frequency divider winding machine. The capacitor filters the low frequency to the tweeter, and the frequency divider inductor is wound by the frequency divider winding machine to filter the high bottom to the low frequency to the woofer, so as to distinguish the sound signals in different frequency bands in a sound. It has different sound frequency channels, high frequency sound channels can only pass high frequency sound, middle and low frequency sound the same. After the sound is distinguished, the sound is amplified and played in the corresponding sound amplifier, and finally we can get the most accurate audio we want.

Frequency dividers are divided into two categories, one is a power divider, and the other is an electronic divider.

The power divider is set in the speaker, the power amplifier in the speaker first amplifies the sound power, and then the power divider divides it into three audio signals, high, middle and low, and finally sends it to different speakers for playback. The advantage of this power divider is that it is simple and convenient to connect and use, but its disadvantages are also obvious, that is, its power consumption is large and the parameter deviation value is large, the error of the sound frequency is large, and its error is related to the impedance of the speaker, so it is not convenient to adjust.

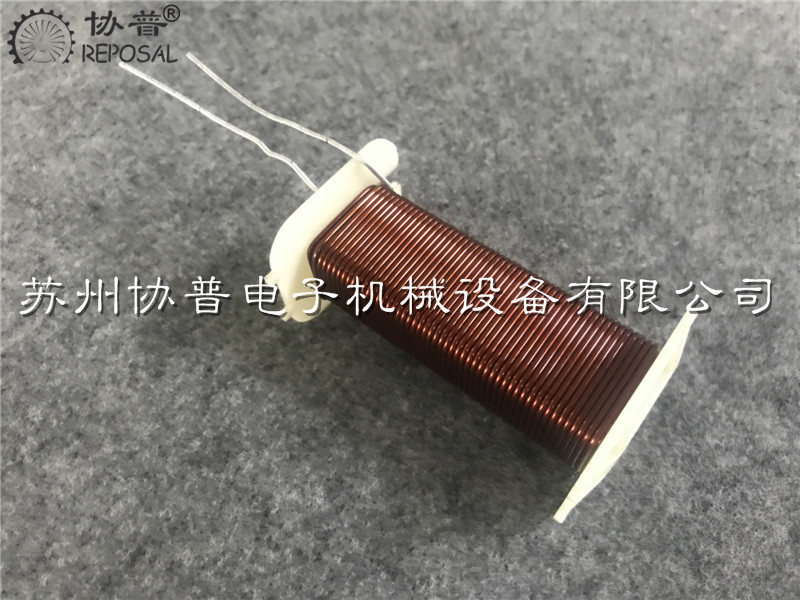

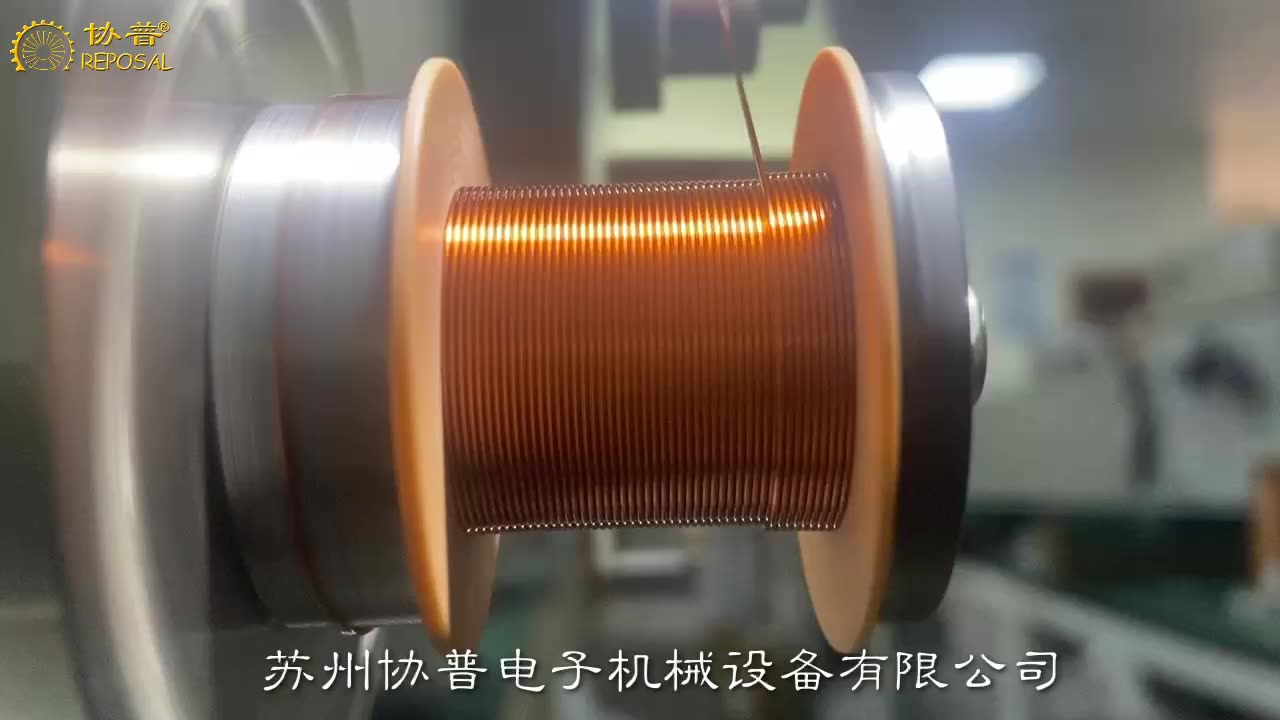

Precision Winding Machine | Hollow Coil Winding Machine | Whole Column Coil Winding Machine

Precision winding machine

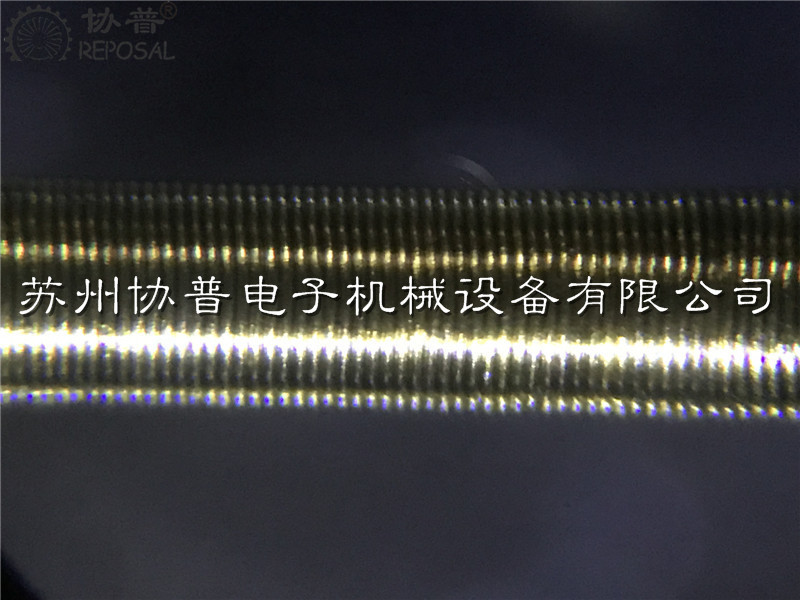

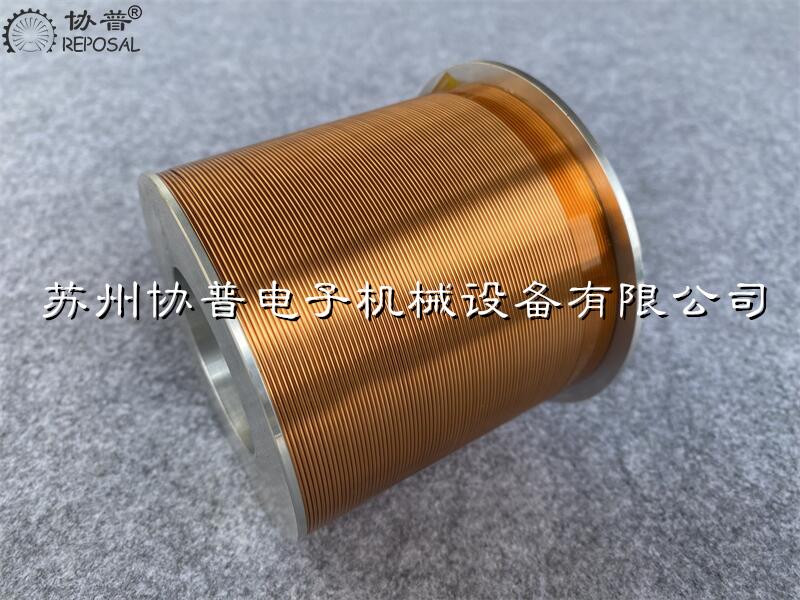

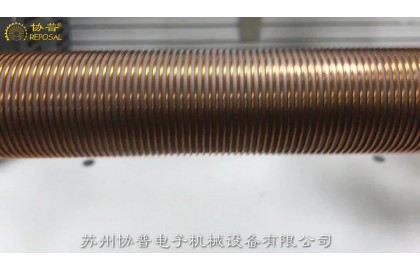

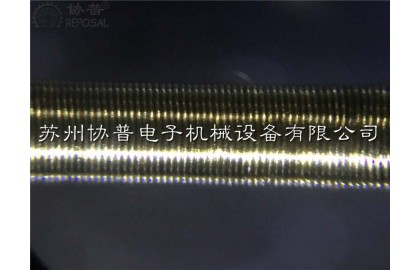

Precision winding machine For general winding machines, including CNC and automatic winding machines, only the set number of turns of enameled wire is required to be wound, and the appearance is roughly flat, but there are some special high-demand occasions , It is required that the arrangement of enameled wires must be neat without a random winding.

This kind of coil has several advantages. First, the consistency of inductance is very high. Second, the enameled wire occupies less space, and the enameled wire can reach the ideal neat arrangement. Third, the energy density is high. Fourth, the high temperature resistance performance is better. , The enameled wires are in line contact, and in the case of random winding, the superimposition between the wires will have a little contact, and it is easy to break down under high temperature and high pressure.

In order to achieve a stable and neat arrangement, in addition to the requirements for enameled wires, compared with general coil winding machines, high requirements are put forward for the electronic control, mechanism design and manufacturing accuracy of structural parts of the fine winding machine.

REPOSAL® Winding Machine successfully overcomes the difficulty in the winding process of closed coils of fixed-length titanium plates with loops.

REPOSAL® Winding Machine successfully overcomes the difficulty in the winding process of closed coils of fixed-length titanium plates with loops.

These tiny looped titanium plates are shown here, small metal structures approximately 12mm long, 4mm wide and 1.5mm thick, and have a row of four circular holes through them, two of which are for The main body pulls the suture through, and the other two upper holes are used for the passage of another group of seam lines. The structure is small in size, and it is necessary to form a closed connecting loop through the structural member, and the closed connecting loop is formed by twisting the yarn fibers of the loose structure. A closed high-strength braided coil is passed through the middle, which seems simple, but its core technology is reflected in the Loop, that is, a high-strength coil, which is woven evenly, tightly, non-woven, and without joints.

This kind of titanium plate with loops is divided into two types, fixed-length type and adjustable type, especially the fixed-length type, whose length ranges from 15mm to 60mm. It is necessary to wind this closed loop in the middle of a titanium plate with such a small volume. Coils, and because the number of colonies cannot exceed the standard, cannot be wound by hand, but must be wound by

equipment, which is extremely difficult to process. Its structural parts are small in size, and the diameter of the holes is only 1-1.5mm. It needs to form twisted yarns under such conditions, so this product has always been processed manually by hand, and its efficiency is low and consistent. Sex is hard to guarantee.

Because of the small size of the structure, the diameter of the hole is only 1-1.5mm, and it needs to form twisted yarn under this condition, so this product has been processed manually, and its efficiency is low. Consistency is difficult to guarantee.

REPOSAL® Winding Machine successfully developed this equipment according to the customer's request, completed the simultaneous formation of a closed loop (including fiber bundles with a loose structure) and passed it to the porous structural parts, and maintained the twisted structure, which greatly improved the closed loop. The winding efficiency, in addition to obtaining the incomparable consistency of pure hand-made, makes the product have the conditions for large-scale production.

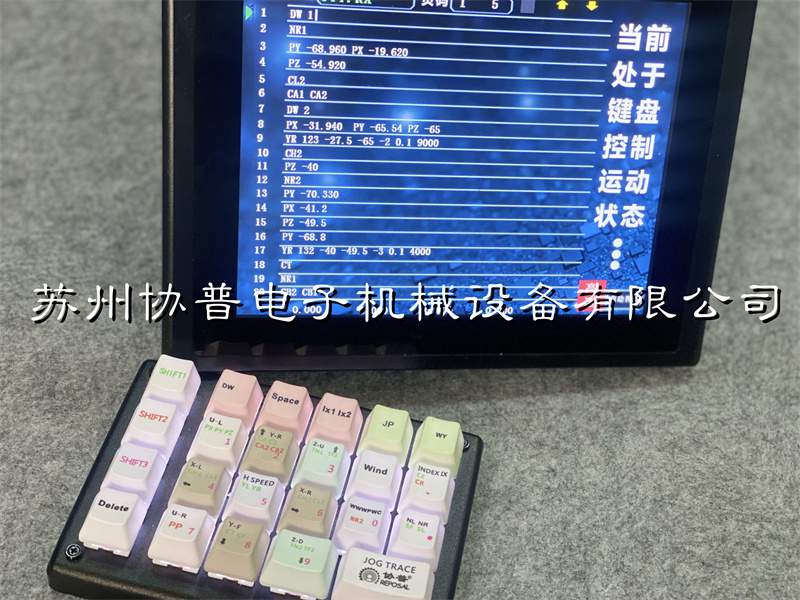

REPOSAL® Winder Releases Coded Teach Winder Control System

REPOSAL® Winding Machine Releases Code-Type Teaching Winding Machine Control System

REPOSAL® Winding Machine, a domestic coil intelligent manufacturing solution provider, has launched its new generation of code programming teaching type winding machine control system that is more open, intelligent and highly autonomous for coil winding enterprises - REPOSAL® Winding machine SP500-R5 system. Compared with the traditional dialog-type winding machine control system, the SP500-R5 system has achieved major breakthroughs in operation logic, technical architecture, and function implementation. Features.

The SP500-R5 system adheres to the concept of "openness and intelligence". Based on the functions of the traditional dialog-based winding machine control system, it integrates the actual needs of the winding factory, and is committed to realizing the coil winding process programming process from the traditional parameter dialog. A major innovation and upgrade from control to code teaching programming.

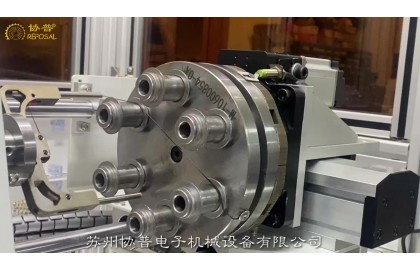

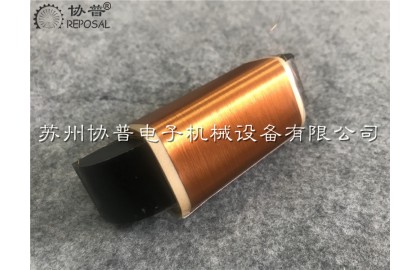

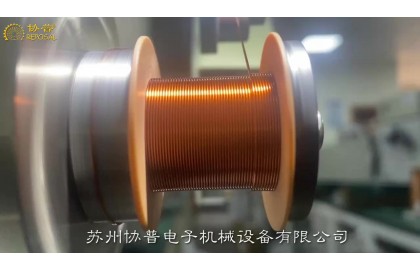

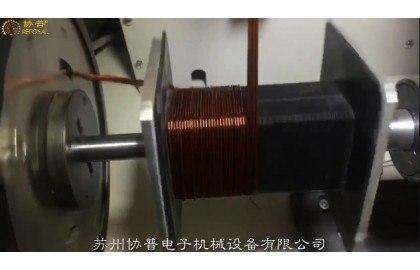

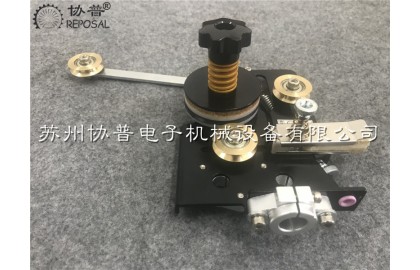

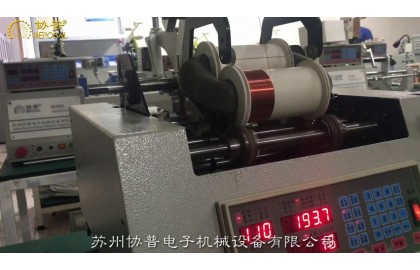

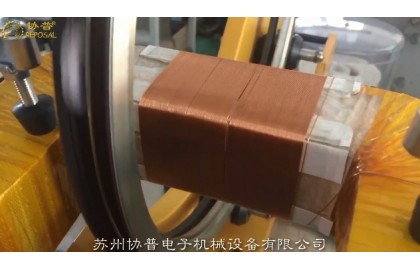

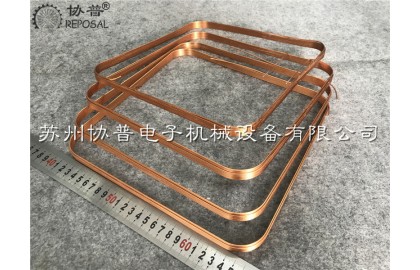

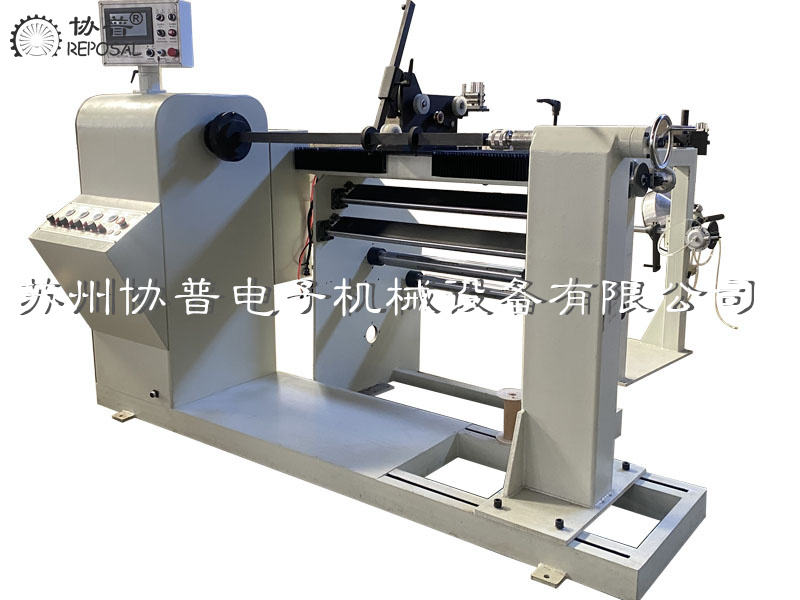

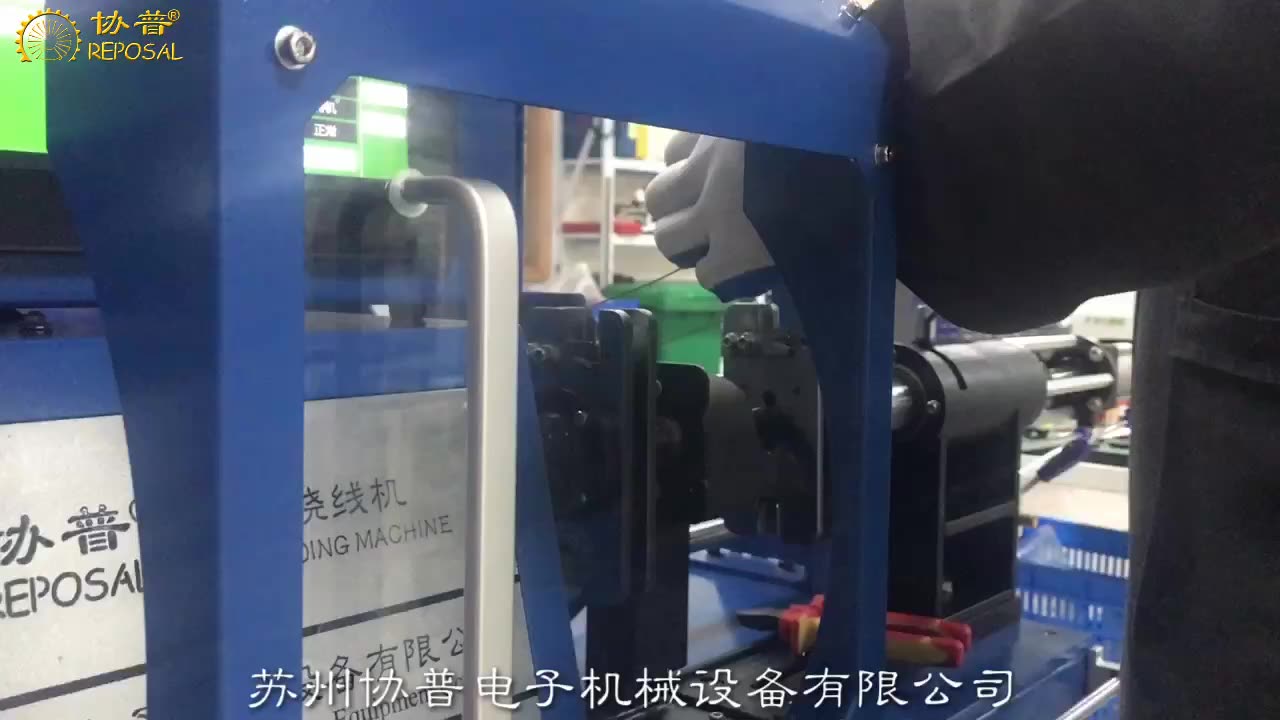

REPOSAL®winding machine's advantages in crossover winding machines

REPOSAL has invested a lot of R&D efforts in the field of crossover coil winding machines and has achieved a series of remarkable results.

In terms of winding accuracy, through in-depth research and optimization of the wiring mechanism and control system, REPOSAL's divider coil winding machine can control the winding accuracy within a very small error range. For example, for the wire with a thin wire diameter, the winding machine can accurately wind according to the set number of turns and arrangement, to ensure that the position accuracy of each turn of wire reaches ±0.05 mm, which greatly improves the quality and performance stability of the coil, and makes the crossover more accurate in the audio signal processing.

In terms of improving winding efficiency, REPOSAL has developed a unique high-speed winding technology. Thanks to the use of an advanced motor drive system and an efficient drive, the winding speed of the winding machine is increased by 30% compared to conventional models. At the same time, combined with the intelligent control system, continuous and uninterrupted winding can be realized, which greatly shortens the winding time of a single coil. For example, a common divider coil that used to take about 10 minutes to be wound by hand, but only 3 to 4 minutes with REPOSAL's winding machine significantly improved production efficiency and provided strong support for large-scale production.

In terms of versatility, REPOSAL's crossover coil winders are highly adaptable. By designing replaceable winding dies and flexible parameter adjustment functions, it is possible to wind a wide range of divider coils with different specifications, shapes and parameter requirements. Whether it's a crossover coil for a miniaturized audio device or a crossover coil for a large professional audio system, high-quality winding can be achieved on the same winding machine. For example, for coil skeletons with different inner diameters, outer diameters and height requirements, the winding machine can quickly switch production modes through simple mold change and parameter setting to meet diverse market needs.

In addition, REPOSAL also pays attention to the research on the convenience and intelligence of the winding machine. A concise and easy-to-understand human-computer interface has been developed, so that operators can master the operation method with only simple training. At the same time, the winding machine also has intelligent fault diagnosis and early warning function, which can monitor the parameters in the winding process in real time, and once there is an abnormal situation, such as wire breakage, abnormal winding tension, etc., it will immediately send out an alarm and prompt the cause of the failure, which is convenient for the operator to deal with in time and reduce the risk of production interruption and equipment damage.

Flexible Driveline Coupling special winding machine

Flexible Driveline Coupling special winding machine

The automobile drive shaft is the part connecting the gearbox and the drive axle. It is a high speed rotating body, and the drive shaft connecting disk is the part balancing the action of the drive shaft.

The structure of the connecting disk of the drive shaft is shown in the figure below:

Existing shaft connection plate is made up of rubber vulcanization six sets of steel, its structural strength mainly provided by the rubber, in order to increase the structural strength, the manufacturer will before die casting vulcanized rubber, between the six sets of steel nylon line, its technology and processing technology is very similar to synchronous belt, between the six sets of steel round the multi-layer nylon thread, die-casting vulcanized rubber, It's a good reinforcement. Such as Mercedes-Benz, Ford have adopted this process.

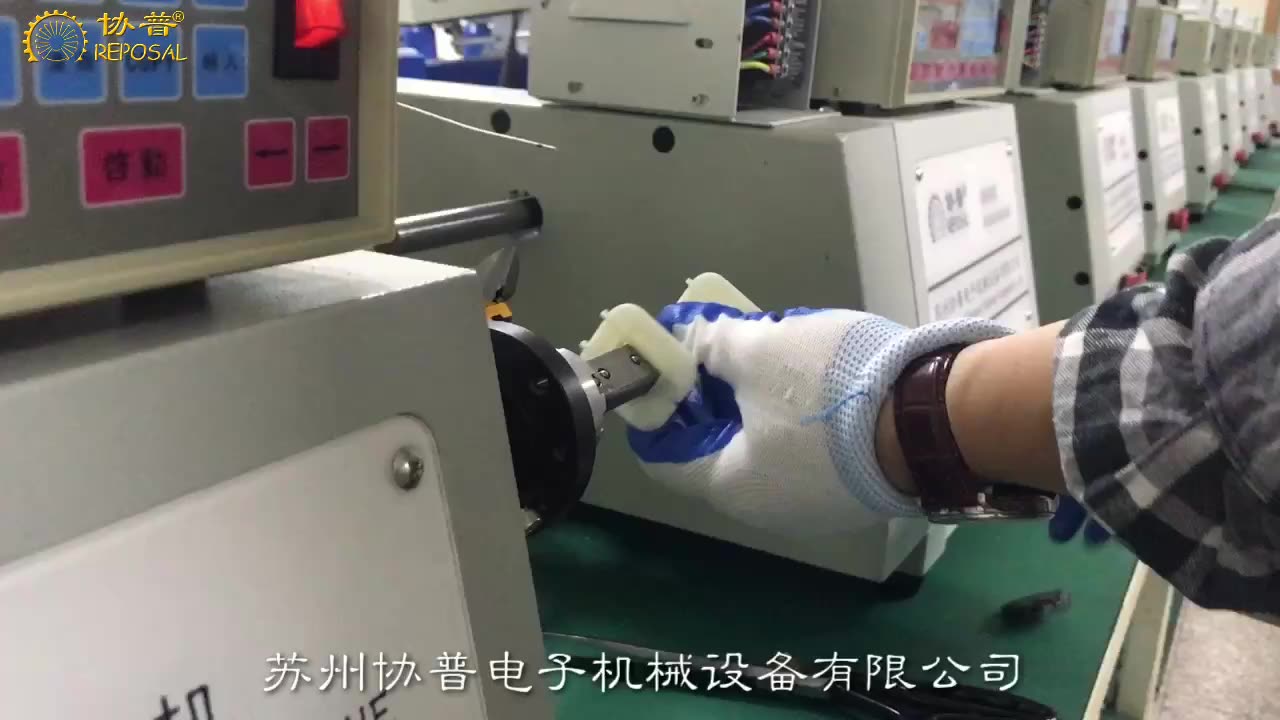

Operation video of belt loop coil winding machine-controller setting

Operation video of belt loop coil winding machine-controller setting

Now we focus on the use of the controller of the toroidal coil winding machine. The controller is very mature. It is divided into several functional areas. This one is the status area. For example, the indicator light before the standby character is on, which is standby. Status, the red light in front of the standby is on. For example, when we press Start, the running light will turn on, indicating that it is currently running. This is a status area.

This is a numeric parameter. When we want to set the parameters of the toroidal coil winding machine, for example, the parameters such as the diameter of the outer diameter and the diameter of the enameled wire, there is still a cable angle for the ring-shaped product. From this position to this position slowly, this involves a range. We use the winding angle and the cable angle to control the cable range on the controller interface, after the specified cable angle , He went back to the line, before and after the set winding angle and line angle.

The other is the speed. The high-speed and low-speed reference on the controller interface of the loop coil winding machine. The high-speed refers to the normal winding speed. The low-speed is the speed at the beginning and the end, and then the number of slow-down laps. Specify a specific number, such as slow speed, you need to specify a lap speed of one lap, two laps and three laps, according to your needs.

Here is a switch parameter area, such as the direction of the winding, such as the storage ring on this toroidal coil winding machine, we can let him turn clockwise or counterclockwise, and then the direction of the cable, the cable The direction is the process of winding the product. We can also let him turn clockwise or counterclockwise. This is the direction of the cable. Whether to start automatically between different programs, this can also be set.

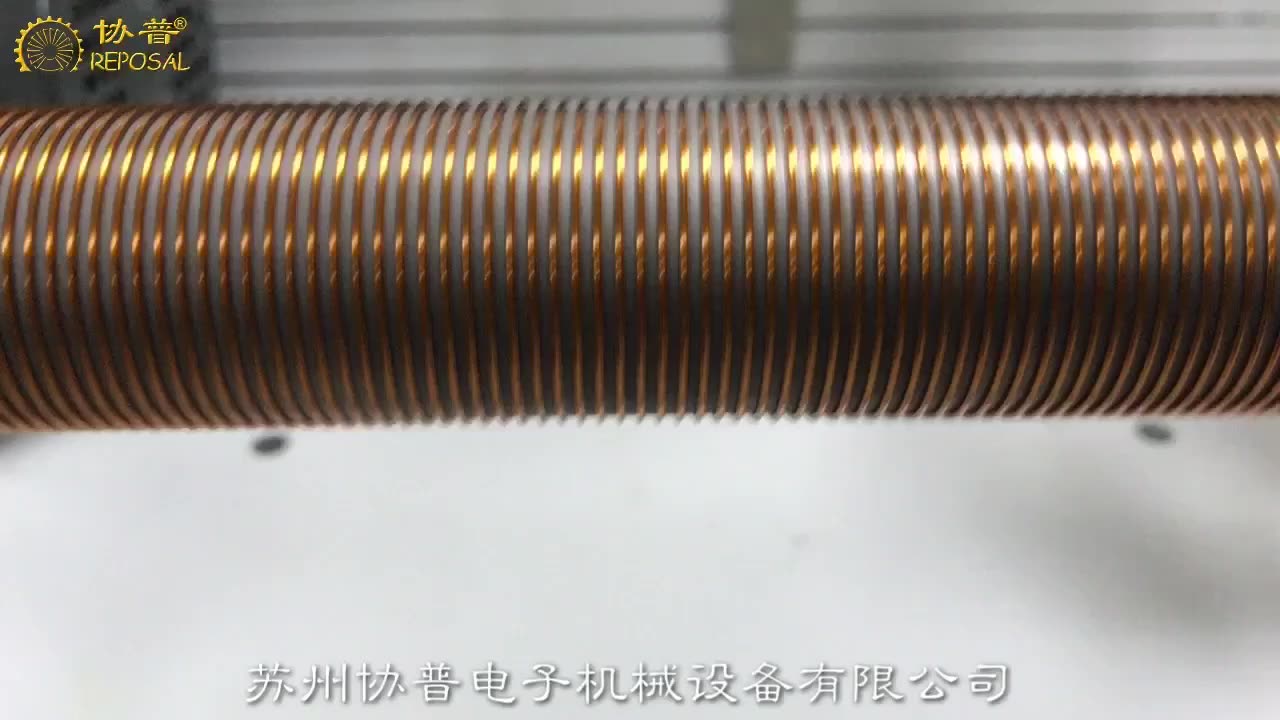

REPOSAL successfully developed string winding machine

REPOSAL takes the string winding machine as the research object and adopts the modal analysis method. Firstly, the vibration principle and the movement principle of the winding mechanism of the small string winding machine are discussed in theory. Based on the principle analysis, the vibration analysis of the ADAMS model of the small copper wire winding mechanism to study the vibration damping characteristics between the roller shaft and the frame is carried out respectively, and the wire winding mechanism of the string winding machine is made using ANSYS software. Modal analysis was carried out for normal operation. Through analysis, the vibration characteristics of the winding mechanism of the string winding machine under normal working conditions are obtained respectively to optimize the vibration damping measures of the winding mechanism. At the same time, the mechanical characteristics of the thin wire and CNC under the normal working state of the CNC winding mechanism are analyzed. , Optimizing the feasibility of applying the CNC cable winding mechanism to the string winding machine cable winding mechanism.

REPOSAL ® winding machine has successfully realized the coil preparation process of the frameless capillary magnetic liquid acceleration sensor

In particular, the non-magnetic material in the magnetic liquid will be subjected to a magnetic field force in the non-uniform magnetic field, which makes many magnetic liquid acceleration sensors can be designed based on this characteristic.

These characteristics make the magnetic liquid acceleration sensor has many advantages compared with the traditional acceleration sensor, such as no wear, high sensitivity and simple structure.

However, most of the existing magnetic liquid acceleration sensors use solid mass blocks as non-magnetic substances, and use coils to detect changes in inductance under different accelerations to obtain output signals. However, its disadvantage is that it leads to complex magnetic circuit and poor sensor stability.

A new solution emerged -- the capillary magnetic liquid acceleration sensor, good stability, simple magnetic circuit, accurate and reliable measurement results and long service life.

REPOSAL ® winding machine to overcome guidance fiber wire winding process difficulties

Guidance communication has an excellent application prospect, but the guided fiber wire package needs to be wound long distance without defects, but because the surface of the fiber is smooth, brittle and easy to break, as well as the residual stress generated by the micro bending will make the signal attenuation, so it is more difficult to wind than other fibers, making long distance fast fiber automatic winding without defects has become a major issue. REPOSAL® winding machine, as a professional winding process solution provider, has been developing process research on precision winding of guided fiber wire packages for many years. Good progress has been made and REPOSAL® special winding machine for guidance fiber wire wrap developed by the winding machine can set reliable process instruction information according to process requirements and accurately execute control commands to finally finish the long distance guidance fiber wire wrap without defects. In the whole research project, we focus on solving three problems of guidance fiber optic wire wrapping system: tension control. Winding system, feeder system, and expand as follows.

REPOSAL's successfully developed precision flexible Roche coil winding machine

Precision Flexible Roche Coil Winding Machine is a special equipment for winding precision flexible Roche coils. With the actual project as the background, Xiepu successfully developed a precision flexible Rogowski coil winding machine by decomposing the flexible Rogowski coil winding process.

The precision flexible Roche coil winding machine does not belong to the ranks of general numerical control equipment, but a special non-standard equipment. For this type of equipment, it is mainly reflected in a special purpose. Since the special purpose means that the market demand is not large, it is indispensable. For equipment manufacturers, the development of such special equipment is not favored, and cost control is very difficult.

In addition, the current domestic manufacturers of flexible Roche coils have limited demand for equipment. At the same time, if you want to control the pitch accuracy and alignment, the equipment research and development costs are relatively high, and the market risk is large. At the same time, for equipment users, their corresponding The supporting equipment and instruments are a large investment.

REPOSAL® machine for radiofrequency ablation catheter

The precise winding process ensures the efficient transfer of energy, thereby improving the efficiency and consistency of ablation. The uniformity of the precision wound coil affects the temperature distribution of the ablation area, avoiding local overheating or heat deficiency, which is essential to ensure the ablation effect and reduce complications. The stability of the winding process ensures the reliability of the operation. The high-quality winding process withstands stretching and bending during surgical operations, reducing the risk of breakage or functional failure. High-quality winding processes have a longer service life and are able to maintain stable performance through multiple operations, thereby reducing medical costs and improving resource efficiency. The quality of the winding process also affects the precise control of the ablation process. The high-precision winding process helps physicians to more precisely control the size and shape of the ablation area to achieve optimal treatment results.

Moreover, the RFA catheter winder is designed with operational safety in mind, reducing potential risks during operation and protecting operators and products from damage. It can adapt to different types of radiofrequency ablation catheter production requirements, and has good flexibility and scalability. The structure and design of special winding machines are often more simplified and easier to maintain and maintain, thus reducing long-term operating costs.

The advantages of radiofrequency ablation catheter winding machine are mainly reflected in professional design, high efficiency production, precise control, quality stability, easy operation, material saving, safety, strong adaptability, low maintenance cost and technological innovation. These advantages make the radiofrequency ablation catheter winding machine an indispensable key equipment in the production process of radiofrequency ablation catheter.

REPOSAL® winding machine has successfully provided competitive solutions to the electron microscopy winding process

The main components of scanning electron microscope are electron optics system, signal collection and processing system, vacuum system, image processing display and recording system, power system and computer control system. The core part is the electron optical system, which is mainly composed of electron gun, electromagnetic condenser, diaphragm, scanning system, astigator, objective lens and various centering coils.

Reposal® winding machine As a professional supplier of precision winding solutions, we focus on the electromagnetic condenser, objective and astigmatic, because the main components are enamoured wire windings, and the precision and consistency of the windings are highly related to the image quality of the scanning electron microscope.

Electromagnetic lens coil.

The electromagnetic lens is mainly used to restrain the electron beam and it can be regarded as a convex lens in optics. Because the electron beam in a rotating symmetric magnetic field will be subjected to the Lorentz force, resulting in a focusing effect. Therefore, the quality of the enamelled wire winding coil that can generate this rotationally symmetric rather than uniform magnetic field and make the electron beam focus imaging is very important.

The enamelled wire winding coil in the magnetic lens, when the current passes through the coil, the pole shoe is magnetized, and a magnetic field is established in the heart cavity, producing a focusing effect on the electron beam. There are two kinds of enamelled wire winding in the magnetic lens, namely, the enamelled wire winding of the condenser and the enamelled wire winding of the objective lens. The lens near the electron gun is the enamelled wire winding of the condenser, while the one near the sample is the enamelled wire winding of the objective lens. General condenser is the high excitation lens enamelled wire winding, high excitation lens enamelled wire winding has many turns, a cylindrical multi-layer arrangement, requires good rotation symmetry

REPOSAL® Winding machine Optimum design of CNC winding machine for large power transformer

In the manufacture of power transformers, winding the transformer coil is a super important step, you think, the transformer coil is wound more firmly and neatly, the strength of the transformer and the ability to protect against short circuits can be greatly improved. However, most of the current transformer winding machines have to rely on manual extra sorting of the coil, the entire equipment is low in automation, and the production efficiency is not high, so the development of an excellent large transformer winding machine is a crucial thing for our company.

We have studied the main shaft technology of transformer winding machine, the relationship between compaction force and winding quality, and the control of compaction force. According to the principle and process flow of transformer winding, we put forward a whole design scheme of large transformer winding machine, including mechanical structure and electrical control. Mechanically, we simplify the complex structure of traditional transformer winders. In terms of electrical control, we ensure the stability of the motor when it starts and stops, and ensure that the winding coil is evenly tightened during the winding process. For the core parts of the transformer winding machine, spindle system and pressing device, we have calculated and selected the types and parameters. With the compaction device, we are able to provide real-time axial and radial compaction forces during the winding process of the transformer winding, which is very effective for improving the tightness of the winding.

The static analysis of the radial compaction device of the winding machine is also carried out by using finite element method, and the structure optimization is carried out according to the analysis results. We find that as the number of layers and turns of the winding increases, the required axial and radial compression forces change accordingly. By analyzing the experimental data, we find that there is a maximum value and a minimum value in the range of quality requirements, and it is the most reasonable choice to make the compression force approximately proportional to the number of layers and the number of turns.

The large transformer winding machine developed by our company has been preliminatively debugged and put into the market. After testing, the performance parameters of this transformer winding machine are in line with the design requirements, and the operation is stable and efficient. It can be wound to make a tight and regular transformer winding coil, and has been fully recognized by the market.

As a power grid equipment, power transformer converts voltage through the electromagnetic induction between the winding coils of the transformer. With the continuous development of the market, higher requirements are put forward for the manufacturing level of transformers, and the market needs more energy-saving and efficient transformers. Therefore, the optimization of the transformer manufacturing process is particularly critical. Quality and performance depend on the process equipment. The technical level of the transformer winding machine directly reflects the manufacturing level of the transformer. Therefore, accelerating the development of transformer winding machine is an important guarantee to improve the performance of transformer.

The winding coil of the transformer is the core component of the transformer and constitutes the electromagnetic induction part of the transformer. It generally includes high voltage winding and low voltage winding, respectively connected to the high voltage grid and low voltage grid. The winding of large power transformers usually adopts concentric winding, that is, the high and low voltage transformer winding coils are centrally set on the core column. The manufacture of transformer winding is the core process of transformer, and its quality plays a crucial role in the performance of transformer, affecting the appearance of transformer size, weight, mechanical properties, insulation and heat resistance and other important indicators.

In the past, the production of transformer winding coils relied on manual, and workers had to wind insulated wires manually to the winding die frame in accordance with the process requirements. Turns calculation also have to rely on manual, this old-fashioned method is inefficient, and because the worker's skills are not strong enough, the quality of the winding coil is poor, the number of turns may be miscalculated or missed, and ultimately lead to the finished winding coil performance can not be guaranteed. Later appeared semi-automatic transformer winding machine, which is driven by the motor to rotate the spindle to wind the transformer winding coil, although it improves the production efficiency, but the wiring work still has to rely on manual, only suitable for flat winding transformer winding coil winding, and winding head winding, welding and other operations must still be completed manually, so the product quality is not stable.

Later, with the emergence of TTL logic gate circuits, in the mid-1970s, with the development of CMOS technology, various types of equipment program control a large number of applications of digital integrated circuits, Western countries and Japan and other industrial powers have emerged CNC winding mechanism manufacturing industry. These CNC transformer winding machines represent the advanced level of winding mechanism manufacturing technology, especially the winding equipment produced in Japan, Italy, the United States and Germany is the leading technology.

Now the transformer winding machine as the core parts of the transformer production equipment, the market demand is very large, and the transformer manufacturing enterprises at home and abroad attach great importance to the development and application of advanced technology of transformer winding machine. Domestic transformer winding machine production enterprises are small, insufficient technical reserves, limited research and development funds, so there is still a big gap compared with foreign advanced products, the market share is low, unable to compete with foreign countries. To solve the key technical problems of transformer winding machine is the key to improve the quality of domestic winding equipment and enhance the market competitiveness. In order to meet the demand of transformer manufacturers for high quality and low price winding equipment, especially large transformer winding machine, on the basis of learning from foreign advanced experience, combined with domestic research results, the development of large transformer winding machine has important significance and practical value.

Research and development background and characteristics of precision current transformer winding machine

Research and development background and characteristics of precision current transformer winding machine

The precision of coil in current transformer is very important, because it directly affects the accuracy of current measurement and the reliable operation of power system. The specific importance of coil accuracy is reflected in the following aspects.

Electrical energy metering: In a power system, accurate measurement of current is the key to calculating energy consumption. If the coil in the current transformer is not accurate, it will lead to an error in the measurement of electrical energy, which can lead to a miscalculation of energy costs, with possible financial implications for both the utility and the consumer.

Fault detection: The current transformer is used to monitor the current level to detect abnormal conditions in the power system, such as short circuit and overload. If the accuracy of the coil is not high, it may lead to false positives or neglect of potential faults, which affects the reliability of the power system.

Overcurrent protection: Current transformers play a key role in overcurrent protection devices, detecting overcurrent events and triggering circuit breakers or other protective devices. The accuracy of the coil directly affects whether the overcurrent can be accurately detected to ensure the safety of the power system.

Load management: The load management of a power system requires accurate measurement of current in order to make reasonable load distribution and adjustment. If the precision of the coil is not high, it may lead to unbalanced load distribution, affecting the efficiency and stability of the power system.

Automated control: In modern power systems, automated control systems rely on accurate current measurement data for real-time adjustment and control. The precision of the coil is critical to the response speed and performance of the system.

Waveform analysis: Current transformers are also used for power quality analysis, including harmonic analysis. The precision of the coil determines the accurate analysis of the current waveform, which helps to solve the power quality problem.

Study on the control of the speed curve of the coiling machine for precision coiling machine

Your factory is using a traditional winding machine, your wire machine structure is reasonable, high mechanical accuracy, the motor is also used a big brand of motor, but in the winding of precision coils, there will be a high defect rate, you carefully analyze before improving various factors - equipment structure, processing accuracy, tooling accuracy, skeleton accuracy, enamel wire quality, tension control, etc. But it still doesn't solve the problem. But to tell you that it's not just a hardware problem, but an algorithm problem, may surprise you. Because in your opinion, every time the spool is transferred, the spool has a corresponding response, but in fact, you may not have considered that in the winding process of the precision coil, the wire guide pin is connected at both ends of the coil, and the sudden change in speed may cause the coil to cross the line and be raised. These defects can degrade the performance of the coil.

To solve this problem, we propose an acceleration and deceleration method based on 5-segment S-curve. The algorithm uses linear acceleration or deceleration at the end and end of the line motion control to help reduce coil defects. We first verify the feasibility of the algorithm by using ADAMS software. The software simulates the motion of the precision winding coil and obtains the velocity curve and displacement curve during the motion. Later, the experimental results show that the method of adopting S-curve in the alignment speed control can reduce the coil defect by up to 50%. This shows that the 5-section S-curve motion control algorithm is a promising method to improve the precision and efficiency of the winding process of electric precision coils. By using this algorithm, coil manufacturers can reduce the risk of coil defects and improve coil performance.

Winding machine is a special production equipment for precision winding coils. They can be divided into stator winding machine, flying fork winding machine, ring winding machine and flat winding machine according to the working mode and object. Different types of equipment are suitable for the production of different objects. For example, the stator winding machine is mainly used to produce motor stator coils, while the parallel winding machine is used to produce electromagnetic switching coils.

Ordinary algorithm of parallel winding machine in the production of precision winding coil products, although our mechanical structure, parts processing accuracy has been done very well, but often there is a problem of low wiring accuracy. In the process of winding a line coil, there are two main movements, one is the rotating movement of the skeleton, which is called winding movement, and the other is the translation movement of the guide needle, which is called wiring movement, and wiring transport is matched with winding movement. After years of technical accumulation, we analyze that the leading role in the alignment accuracy is the alignment movement of the guide needle. Therefore, if you want to improve the alignment accuracy of the coil, you need to optimize the alignment movement of the guide pin.

In fact, we have always believed that the winding machine is equivalent to the lathe in the electrical industry, its importance is self-evident, so for its accuracy, there have been many experts and scholars to study this.

Some people studied the mathematical model of precise alignment based on axial pressure compensation around the axis in the process of alignment. The axial pressure was used to improve the alignment regularity of the coil, and the mathematical model was established according to the analysis of the end point of the coil alignment, which improved the alignment accuracy of the coil.

Some people use the 5-section S-curve control algorithm and the 7-section S-curve control algorithm respectively in the research. In motion control, the 7-section S-curve is more complicated than the 5-section S-curve control. This method has achieved more results in the field of CNC machining, but it is not mature in the field of winding machine.

The tension instability caused by the friction between the enamelled wire and the conductor nozzle during coil winding has been studied, which leads to the uneven wiring of the coil and the breakage of the enamelled wire.

Some people have studied the low efficiency of the winding machine in the traditional winding control because of the inertia error in the process of the winding machine. Instead, the servo motion wiring and the inertia error supplement are used to improve the control efficiency of the winding machine.

PLC control is commonly used in the winding machine wiring control system, through PLC control servo motor can realize the winding machine wiring control, both PLC control stability and high precision servo motor advantages. However, there is a sudden impact of guide pin speed in the coil alignment of parallel winding machine, so it is necessary to further optimize the change of guide pin running speed to improve product quality and the smoothness of wire alignment speed. The S-curve algorithm is a kind of smooth transition of speed in the process of motion, which is often used in machining to solve the problem of breaking the tool caused by speed impact and improve the precision of machining products. In the winding machine, the speed of the guide needle can be changed into an arc smooth transition by controlling the movement track of the guide needle, improving the alignment accuracy and product quality.

To sum up, an algorithm based on 5-segment S-curve motion control is proposed to solve the problem of velocity shock in the process of coil alignment by analyzing the law of coil alignment. ADAMS software is used to simulate the trajectory of the guide pin to verify the feasibility of the algorithm. And the application of the example proves that the 5-section S-shaped curve can effectively solve the phenomenon of crossing and protruding in the process of winding, and improve the precision of winding.

Coil wiring principle

The winding method is flat winding, that is, the enameled wire moves synchronously with the guide pin and always keeps perpendicular to the skeleton during winding. The frame is driven by the winding motor with the guide needle movement, the enameled wire is wound on the skeleton, in which the guide needle is located in the wiring arrangement mechanism and the winding mechanism are two independent mechanisms. The winding mechanism is divided into three stages according to the motion process of the guide pin, namely acceleration and deceleration stage, uniform speed stage and end point return stage. The acceleration and deceleration stage can be divided into two parts: acceleration stage and deceleration stage. In the early stage of the alignment movement, the guide pin speed from zero to uniform speed belongs to the acceleration stage. At the end of the alignment movement, the process of decelerating until the speed reaches zero is a deceleration stage. The middle constant velocity stage is the constant velocity motion stage of the guiding needle. The terminal reentry stage is a process in which the guide needle accelerates backward again after slowing down and stopping. Here we explain:

Acceleration and deceleration stage

In order to arrange the lines evenly, the two movements of guide pin movement and skeleton rotation should meet certain coordination relations during acceleration and deceleration stage. The time for the guide needle to move one diametral width distance must be equal to the time for the skeleton to rotate once, that is, the guide needle to move just one diametral distance when the skeleton rotates once.

The advantages of Type R transformer and the status quo of type R transformer winding machine

Although R type transformer is widely used, but in fact the production of manufacturers are not many, the reason is limited by the R-Core transformer winding machine, so far, there are many R-Core transformer winding machine is the principle of manual wiring, so its winding production efficiency is relatively low, Up to now, many factories are using manual winding in the winding of R-shaped transformers.

In response to this situation, we have launched an automatic R-Core transformer winding machine with high precision, complete functions, easy to use, stable and cost advantages, which has been widely recognized by customers since its launch. Our R type transformer winders have the following features:

1. R-Core transformer winding machine special controller, high precision, stable and reliable, easy to operate, computer (single chip microcomputer) control, full key operation, working state digital display.

2. 1000 sets of process data can be stored and called, and it has the function of button and foot start and stop, and the speed can be increased and decreased during the winding process.

3. Handle built-in start-stop switch, which can improve efficiency, especially convenient for debugging.

4. The configuration of a first-line brand laser amplifier, long life, high precision, low failure rate, stable and reliable counting, laser amplifier installation structure optimization, can be far away from the coil skeleton end face accurate and reliable detection of the number of turns, fundamentally solve the probe collision roller and skeleton movement brought about by the count unreliable problem.

5. R-Core transformer winding machine press wheel adopts step bearing design, which can effectively control the axial movement of the skeleton in the rotation process.

6, the controller has complete functions: abnormal alarm function, such as overload, reverse wiring direction, speeding and so on.

7. Linear acceleration and deceleration function can be set at the beginning and end of winding, which can eliminate the sudden acceleration and deceleration effect and avoid disorderly or broken lines.

Toroidal coil winding machine operation video-Machine operation

Below we introduce the structure of this toroidal coil winding machine. This part is the controller and this part is the clamping base. We control the product clamping by opening and closing the handle. This position is the storage ring. The enameled wire is stored on the storage ring first, and then wound around this product. This position is a manual winding handle. Turn this handle. The steel plate can be driven manually. The steel ring has an opening. This position is an opening. The opening is opened and closed by sliding the handle up and sliding to the left. . This position is called the crimping plate, and this position is called the baffle. After the line is removed, its degree of tightness is determined by the tension of the belt. The tension of the belt is adjusted by the tension adjustment knob. When adjusting the tension of the belt, first loosen this And then rotate the handle. When rotating the handle, there is an idler wheel. When the idler wheel goes in, the tension of the belt will increase, so that the winding of the enameled wire will become tighter.

Transformer winding machine

Transformer winding machine:

Similar to transformers, current transformers also work according to the principle of electromagnetic induction. The transformer transforms voltage and the current transformer transforms current. The current transformer is connected to the winding of the measured current (the number of turns is N1), called the primary winding (or primary winding, primary winding); the winding connected to the measuring instrument (the number of turns is N2) is called the secondary winding (or secondary side) Winding, secondary winding).

This ring current transformer winding machine is generally used to wind small size current transformers. The characteristics of small size current transformers are generally wire diameter of enameled wire between 0.11-0.19mm, and the number of turns is large.

It requires accurate turns and fast winding speed.

REPOSAL this machine is fast and stable, and the speed reaches 1400RPM. Because it is stable, it can realize the operation of multiple ring current transformer winding machines by one person.

U-shaped core winding machine

Transformer coil winding machine

Stable, high-speed and safe U-shaped core coil winding machine

The U-shaped coil winding machine is suitable for the winding of the bottom edge of the U-shaped core.Usually, the center of the U-shaped core is difficult to coincide with the rotation axis of the winding machine, resulting in a large vibration of the winding machine. , Affecting efficiency.

This type of winding machine developed by our company does not rotate the U-shaped iron core, only reciprocates, and rotates around the product to reduce vibration and improve efficiency.

With the optimized clamping method, it only takes 2 seconds to complete the clamping.

Therefore, the rotating parts of this type of machine have a large diameter and a high speed.There are similar machines on the market, and the larger ones do not have a protective cover. Safety accidents often occur.This machine of the company has a protective cover design.

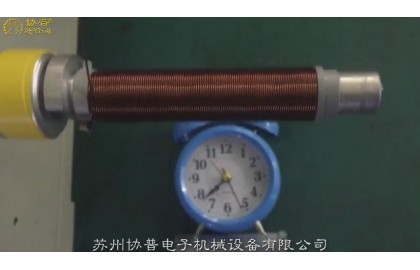

REPOSAL® releases Automatic winding machine

Suzhou REPOSAL® Electronic Machinery Equipment Co., Ltd. released: automatic induction coil winding machine.

This model is mainly used for the winding of rod-shaped inductors. During the winding process of this winding machine, the rod-shaped inductor realizes unattended full automation. Its winding speed is fast, inductance consistency is good, and debugging Convenient and easy to maintain, it provides a competitive solution for the winding process of rod-shaped inductors for the cooperative customers of REPOSAL®

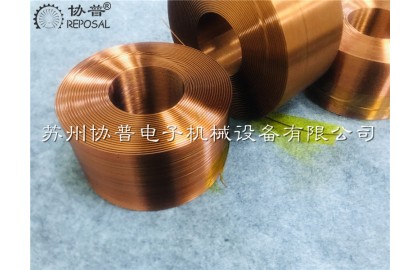

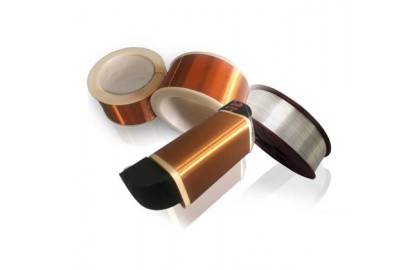

REPOSAL® releases double-wound thick wire diameter air core coil winding machine

Suzhou REPOSAL® Electronic Machinery Equipment Co., Ltd. released the sp-s112hb double-wound thick-wire air-core coil winding machine model-this model is mainly for the air-core coil with a large enameled wire diameter, and the winding speed is fast and consistent. Good performance, through the optimization of the control system and machinery, during the winding process of the larger enameled wire diameter air-core coil, it provides customers with a competitive solution for wire end fixation, tension control, winding accuracy, and demolding speed.

Suzhou REPOSAL® Electronic Machinery Equipment Co., Ltd. released the sp-s112hb double-wound thick-wire air-core coil winding machine model-this model is mainly for the air-core coil with a large enameled wire diameter, and the winding speed is fast and consistent. Good performance, through the optimization of the control system and machinery, during the winding process of the larger enameled wire diameter air-core coil, it provides customers with a competitive solution for wire end fixation, tension control, winding accuracy, and demolding speed.

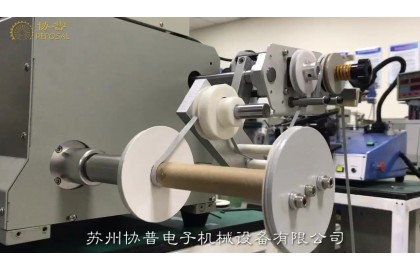

REPOSAL® releases layer-wound high-voltage package full-automatic interlayer insulation winding machine

REPOSAL® releases layer-wound high-voltage package full-automatic interlayer insulation winding machine

Suzhou Xiepu Electronic Machinery Equipment Co., Ltd. successfully released the SP-D102M7 model of layer-wound high-voltage package automatic interlayer insulation winding machine-this model greatly improves the winding efficiency of layer-wound high-voltage package coils, and the coil is consistent Sex. The REPOSAL® winding machine reduces the winding cost of the layer-wound high-voltage package. In the new model, it has added a compact insulation belt automatic cutting mechanism, and high-quality solutions such as dynamic balance performance after multiple skeletons are wound.

Application of toroidal coil winding machine in craft products

Application of toroidal coil winding machine in craft products

Automatic tape wrapping machine

Suzhou REPOSAL®Electronic Machinery Equipment Co., Ltd. developed a fully automatic iron core coating machine,

The diameter of the processed iron core is between 6mm-16mm, the processing speed is fast, the operation is stable, and the accuracy is high.

Clamp Ammeter Coil Winding Machine|Clamp Meter Coil Winding Machine|Semicircle Transformer Winding Machine

Clamp Ammeter Coil Winding Machine|Clamp Meter Coil Winding Machine|Semicircle Transformer Winding Machine

The semi-circular coil winding machine developed by Suzhou Xiepu Electronic Mechanical Equipment Co., Ltd. is suitable for the winding of semi-circular skeleton, iron core and magnetic core coil. Its running operation, high speed, safety cover is convenient and practical. Fast and repeatable positioning accuracy. Applicable products are: semi-circular transformer coil, semi-circular heating wire coil, clamp meter coil, etc.

Common mode inductor winding machine 2

The function of common mode inductor is to suppress common mode interference, and it is a relatively important filter inductor.

It is different from a differential mode inductor. Although the two types of inductors are filter inductors, the different functions determine the appearance and winding method will be different. For the common mode inductor, it is wound on the same core, and the two The coil diameter of each winding is the same as the number of turns, but the winding direction is opposite. A set of coils has two pins, so the common mode inductor has 4 pins; while the differential mode inductor is wound on a core and only has A coil, so it has only 2 pins, so the common mode inductance and the differential mode inductance can be distinguished from the number of pins.

Also because the common mode inductor is two windings with opposite winding directions, the ideal winding effect is that the arrangement of the positive and negative directions is neat.

Craft hanging ball winding machine

Craft hanging ball winding machine

Craft nylon wire winding machine

Craft nylon wire winding machine

Double wire parallel winding ring coil winding machine

Double wire parallel winding ring coil winding machine

Five-wire winding machine

Five-winder winding machine,

The winding diameter is 1.0mm, and the customer has already purchased a winding machine once, which cannot meet the requirements for use.

After a careful evaluation, Xiepu gave corresponding solutions and successfully realized customer requirements.

Gear type ring coil wrapping tape machine

Gear type ring coil wrapping tape machine

Compared with the belt-type loop coil tape belt machine, the gear-type loop coil tape belt machine has a larger processing range and more storage capacity. Our company's gear-type loop coil belt tape machine can be coated with polyester film and polymer Imide, cloth tape, glass fiber tape, etc.

We now open the clamping seat of the gear-type ring coil tape belt machine, the storage ring opens, and then put the product on, the storage ring buckles, the clamping seat merges, and then pay attention to the insulating tape must pass through the middle of the scissors, etc. Cut it off with scissors at once, and then go in from any bearing above the storage ring from the outside to fix the tape head behind the storage ring. The first few laps are slow because they are in storage. Ok, the product is finished, now we take it off, and then close the storage ring, the clamping seat is restored.

High and low speed switching of winding machine controller

Motor winding machine, the early control mode is high and low speed mode, the No. 3 terminal of the controller is connected to the com terminal of the frequency conversion, and the No. 6 line is connected to the segment speed input terminal of the inverter. When the No. 3 terminal is disconnected from the No. 6, the frequency conversion The inverter outputs a set high-frequency power supply. When terminal 3 and terminal 6 are disconnected, the inverter outputs a set low-frequency power supply. After the improvement, the terminal 3 and 6 of the REPOSAL' s winding machine controller The No. terminal will output a 0-10V analog voltage to the inverter according to the value set on a controller, and the No. 3 terminal and No. 6 terminal are connected to the com and Ain terminals of the inverter (Taiwan Dongyuan inverter), the inverter According to the different voltage signals received, output power at different frequencies.

REPOSAL's winding machine controller is compatible with two control methods, and can be switched between the two methods according to customer requirements. See the video description for the specific switching direction.

High-speed precision winding machine SP-112DHS

High-speed precision winding machine SP-112DHS

Horseshoe hollow cup motor coil and winding machine

Horseshoe hollow cup motor coil and winding machine

In recent years, China has paid more and more attention to hollow cup motor and automatic winding technology, and has made good progress and breakthroughs in the research and development and manufacturing of winding machine equipment.

One of the key reasons for the impact on the performance of the motor is the rotor coil in the motor, the rotor in the hollow cup motor has no iron core, small inertia, excellent functionality and a wide range of applications. In addition, in the research and development of coil winding equipment, the saddle-shaped coil arrangement is regular, and the utilization efficiency of magnets is high.

Compared with the old traditional motor with an iron core, the energy conversion efficiency is significantly higher than the latter, and the reaction speed will be much faster, and the hollow cup motor has high efficiency, fast response speed and stable performance. Because the hollow cup motor has no lag, additional electromagnetic interference is low, very high motor speed can be achieved, and the speed setting is sensitive at high speed, so it has relatively stable and stable performance. In addition, the energy density of the hollow cup motor is much greater than that of other motors, and the weight will be much less than that of an iron core motor with the same power.

Now according to the forming method of the coil, in the hollow cup motor coil, its production technology can be roughly divided into two process routes: winding production technology and one molding production technology.

Compared with the two methods, the first winding production technology is more complex, and the efficiency of winding the coil is relatively low. In order to improve the winding efficiency of coil production, the winding machine can be added to the production process of one molding. According to the hollow cup coil shape and winding method, the common hollow cup winding method can be divided into three kinds of parallel straight winding, saddle winding and oblique winding. The first parallel straight winding is generally used for hollow cup motor winding with relatively few turns. The last two are the two coil winding processes commonly used by the relatively advanced hollow cup motor manufacturers abroad.

Influence of low enameled stress on formability in the process of winding enameled wire by winding machine

1 The formability of the enameled wire The mechanical properties of the enameled wire are divided into the mechanical properties of the conductor and the paint film. In the process of winding the enameled wire, in the wire embedding process, and in the electrical products using the enameled wire coil as a component, mechanical stress acts on the enameled wire during operation, so the enameled wire may be elongated and the paint film is damaged. etc. phenomenon. Therefore, enameled wire has the requirements of elongation, rebound angle, softness, tensile strength, paint film elasticity, paint film adhesion and scratch resistance.

1.1 Mechanical properties of conductors: softness, elongation, rebound angle, and tensile strength.

Elongation reflects the plastic deformation of the material and is used to assess the ductility of enameled wires. The springback angle and softness reflect the elastic deformation of the material and are used to evaluate the softness of the enameled wire. The tensile strength is related to the recovery recrystallization degree of the conductor and the grain size of the recovered tissue. The tensile strength, softness and elongation reflect the quality of the copper material and the degree of enameled annealing, which have a great impact on the quality of the winding. great relationship.

In the process of enameled wire coating, if the number of paint passes and the number of loops is too large, and the diameter of the guide wheel is not large enough, the wire will be continuously deformed by alternating tension and compression, resulting in the distortion of the lattice. It breaks easily when stretched. When the enameled wire is running, the wire is subjected to excessive tension, which will make the wire thinner. At this time, due to the displacement of atoms or ions on the lattice due to sliding, residual internal stress has been formed, so the wire is brittle and elongated. rate and softness rate decreased.

Instructions for use of magnetic damping tensioner for winding machine

Instructions for use of magnetic damping tensioner for winding machine

Instructions for use of side-sliding transformer winding machine

Instructions for use of side-sliding transformer winding machine

Instructions for use of standard winding machine tensioner

Instructions for use of standard winding machine tensioner

Insulation tape winding machine

Insulation tape winding machine

Introduction of winding method of electric heating tube

This type of winding machine of Xiepu has a stroke of 1.5 meters, adopts pneumatic quick assembly and quick disassembly, convenient operation, mature and stable structure, easy maintenance, easy operation of the system, complete functions, and strong expandability.

At present, according to customer requirements, a heating coil with a stroke of up to 1.5 meters is wound on this machine. Because the equipment is structured in place, the winding has a satisfactory effect. The customer currently plans to add mica tape winding function on this basis.

Magnetic winding 1mm diameter enameled wire double wire and wound

Magnetic winding 1mm diameter enameled wire double wire and wound

Micro toroidal coil winding

Before winding:

Outer diameter 7.5mm

Inner diameter 4mm

Height 2.3mm

Enameled wire diameter: 0.17mm

80 laps.

Precision CNC winding machine

In the process of winding the coil on the precision automatic winding machine, the coil enameled wire is placed in a spiral shape in each layer. Since the direction of movement from one layer to the other changes between the opposite directions, part of the wires intersect and part of them lies in the gap of the lower layer. If the guiding structure of the lower layer does not exist, and if the number of layers exceeds a certain limit, the structure cannot be maintained, and disorderly windings are produced. At this time, as a temporary measure, it can be improved by using a separate thicker insulating layer.

When most of the circumference of the winding is parallel to the coil flange surface, the smallest coil volume can be obtained. If the winding action of the precision automatic winding machine cannot be performed correctly, the self-directing ability of the wire will be lost, and a disorderly winding structure will be produced. In general, the first layer of basic coil mainly determines the location and quality of the winding step. Therefore, in order to make the winding self-guide to be able to execute correctly, the algorithm and accuracy of the precision automatic winding machine are very high requirements.

It is not difficult to find that when the precision automatic winding machine is winding the coil, the enameled wire needs to enter the winding space as tangentially as possible. In this way, unnecessary excessive bending of the wire is avoided, and the space required for the second layer winding is minimized. For the neatly arranged coils, the winding crossover part should always be located in the area of the wire entering the winding space, and extend continuously in the opposite direction relative to the previous layer of winding in a spiral form. As a result, the larger winding width of the coil results in a larger winding step area along the circumference of the coil. Compared with the enameled wire entry point, the offset created from the first layer to the second layer causes the position of the layer steps to be different. This phenomenon repeats in each layer, thus forming a spiral cross section on the side of the winding. Since the enameled wires cross in the crossing area, the winding height is increased. As a result, a sinusoidal-wound coil with a grounded circular coil will never be circular in cross section, but radially moving windings and layered steps will produce a hump shape.

Precision winding machine

Precision large torque winding machine:

With the continuous improvement of the technical level, people have more and more stringent requirements on the winding of transformer coils, hoping that each enameled wire can be like

The ideal sorted arrangement has the following benefits.

First, in the case of neat arrangement, the enameled wire with limited space accounts for a much larger proportion than the irregular arrangement

The second is the wire saving.To achieve the same energy density, less neatly arranged copper wire is consumed than if it is neatly arranged.

The third is the consistency of the product, because the neat wiring, so the copper consumed by each coil is more consistent.

Of course, there are advantages of heat dissipation and high temperature resistance.

Despite the above advantages, but for a long time, it was thought that the equipment manufacturers were powerless, and it was difficult for people to do it smoothly with machines.When there is such a requirement, people usually use manual processing.

Wire the cable by hand, hit an irregular place, stop, handle it manually, and then slowly wind it.For a long time, people have done this.

Now all this has changed. We have successfully developed a precision large torque winding machine . Through control and mechanical optimization, we have done so.

It takes a long time, but now only a simple training is required.The precision large torque winding machine makes what was impossible before possible.

R-type transformer winding machine

The cross section of an R-type transformer is like the letter R, so it is called an R-type transformer. The application of R-type transformers in high-power electrical appliances can reduce inrush current. R-type transformers are one of the dry-type transformers. The iron core is made of continuous high-quality oriented cold-rolled silicon steel strip from thin to thick, and then from thick to thin. The final cross-section is close to a circle, and the shape is an uncut closed rectangle, and then passes through a special R-shaped transformer The winding machine winds the coarse secondary on its PBT skeleton. Therefore, the transformer thus manufactured has no noise, low magnetic leakage, low no-load current, low iron loss, and high efficiency; and because the coil is cylindrical, the length of the coil copper wire wound by the R-type transformer winding machine short, so , Low internal resistance, low copper consumption, low temperature rise, low over-carrier motion, and better explosive force than toroidal transformers; in addition, the primary and secondary coils are separately wound with flame-retardant PBT engineering plastic skeletons, thus high electrical strength , Good flame retardancy.

However, the manufacturing process is more complicated. The second is the winding of the coil. Because it is wound in a closed iron core, the PBT is composed of two parts, and then the R-type transformer winding machine drives the PBT skeleton to wind, and the winding accuracy is affected. A certain influence, one is the shape of its iron core, because its expanded shape is a spinning cone, so its mold and material utilization are relatively low.

With the development of R-type transformer winding machines, the reduction of manufacturing costs, and the improvement of quality stability, R-type transformers are being favored by more and more electronics industries with their novel and unique structure and excellent electromagnetic performance. Especially suitable for medical equipment, display equipment, audio equipment, office equipment.

Rectangular closed coil winding machine

Rectangular closed coil winding machine

Rectangular core winding machine

Rectangular core winding machine

Rectangular thick wire diameter precision forming self-adhesive inner shrinkage stripping winding machine

Rectangular thick wire diameter precision forming self-adhesive inner shrinkage stripping winding machine

REPOSAL Winding Machine® Released high-speed precision synchronous winding machine

Suzhou REPOSA Electronic Machinery Equipment Co., Ltd. releases high-speed precision synchronous winding machine

REPOSAL Winding Machine® Released Tandem flat-wound winding machine

REPOSAL Winding Machine® Released Tandem flat-wound winding machine

REPOSAL Winding Machine® Released Precision Automatic Paint Stripping and Wire Breaking Winding Machine

Suzhou REPOSAL Electronic Machinery Equipment Co., Ltd. releases

precision automatic paint stripping and wire breaking winding machine

In the inductive coil

winding process, the winding process requirements of the coil are quite

different.The diameter of the enameled wire varies from thin to thick, the

structure of the coil varies from disk to column, and the type of enameled wire

ranges from ordinary to self-adhesive wire. Therefore, for a coil winding

factory that does not emphasize competitiveness, the machine required is a

winding machine with a larger range of adaptation, but often a winding machine

with a larger range of adaptation is for each specific specification of coil

winding. Whether it is quality or efficiency, it is difficult to have targeted

competitiveness.

In order to keep our customers competitive in the induction coil winding process, we have developed this winding machine-precision automatic paint stripping and breaking winding machine in response to customer needs.

This model is mainly aimed at coils with a skeleton with a larger

enameled wire diameter. It has several features, one is the fast winding speed,

if it can maintain a faster winding shaft speed when the diameter of the

enameled wire is larger, and the other is the winding line is flat. Through

control and targeted structural optimization, a compact and consistent coil can

be stably wound. Third, there is an automatic paint stripping function. For

thicker non-direct welding enameled wires, adding this function is equivalent

to combining two processes Integrating into one process, the fourth is to add

the function of automatic disconnection.For thicker enameled wires, automatic

disconnection improves efficiency, strengthens consistency, and significantly

reduces the labor intensity of operators.

For

details, please refer to the video. The operation beat of this video is taken

during the acceptance of the machine. The entire operation process is fast and

stable, but in fact, there is still room for improvement in the efficiency of

fixing and dismantling the enameled wire head.

REPOSAL Winding Machine® successfully developed strip product wrapping tape machine

On August 7, Suzhou REPOSAL Electronic Machinery Equipment Co., Ltd. successfully developed a long strip product packaging tape machine.

This equipment is mainly used to wrap insulating tape for strip products, such as long strip ferrite wrapping tape. For long strip products because of the difficult process, artificial wrapping tape is usually used. Ferrite is more brittle due to its nature. It is difficult to automate the processing, and the Xiepu winding machine overcomes the key points of a variety of processes and successfully developed a long strip product wrapping tape machine, which has been put into commercial use.

REPOSAL® successfully developed an ultra-precision flow tube metering heating wire winding machine

On August 6, the first ultra-precision flow tube metering heating wire winding machine independently developed by Suzhou REPOSAL® Electronic Mechanical Equipment Co., Ltd. successfully completed the test, and the performance of each index reached the level of the industry in advanced foreign countries.

At present, the ultra-precision flow tube, a metal tube with a diameter of 0.4mm, a wall thickness of 0.1mm, an inner diameter of 0.2mm, and a special metal wire of 0.03mm are wound. There are single-layer winding, double-layer winding, and double-layer butt-joining winding. Flow tube is required There is no deformation at both ends and the metal wires are arranged neatly. This process technology has been monopolized by foreign companies for a long time, and the price is high, which severely restricts the research and achievement of ultra-precision flow meters in China.

Ultra-precision flow tube metering heating wire winding machine is an important symbol of independent innovation ability. The research of this equipment has broken through many key technologies of precision winding technology and optimized the process and mechanical structure. In the next step, Suzhou REPOSAL Electronic Machinery Equipment Co., Ltd. will further optimize the design and production process, reduce the cost of the whole machine, make it better to market, and accelerate the application and industrialization of localized precision winding machines.

REPOSAL® successfully developed linear motor winding machine

The linear motor winding machine developed by Suzhou REPOSAL® Electronic Machinery Equipment Co., Ltd. successfully completed the test, achieved success, and was successfully put into production.

At present, in traditional linear motor winding machines, the stator coils are individually wound and then assembled on the linear motor core in sequence, and then welded between the stator coils. The process is many, the efficiency is low, and there are many process nodes such as manual intervention assembly and welding. At the same time, the quality is unstable, which affects the cost of the traditional linear motor for a long time. The successful research and development of the linear motor winding machine of this specification will further reduce the cost of the linear motor and improve its quality.

Based on the process of this linear motor winding machine, the company has reached a further research and development agreement with long-term cooperative customers to replace the traditional circular stator coil inner winding process. There are two reasons for its cost to apply the company's linear motor After the winding machine, there is a very large drop space. One is because the existing inner winding stator coil has a toroidal core, so the utilization rate of the material is low. The current plan is to design it as an unfolded type. The utilization rate will be at least doubled. The second is the inner winding of the stator coil. Due to technological limitations, its winding method can only be wound by a single wire. The REPOSAL'slinear motor winding machine winds three windings at the same time, and its processing efficiency is tripled. The combination of the two aspects will greatly reduce the cost of the inner winding stator coil.

At the same time, Suzhou REPOSAL® Electronic Machinery Equipment Co., Ltd. will further optimize the design and production process, and strive to continue to reduce the cost of the whole machine under the existing cost advantage, so that the production company can save materials and improve efficiency, while also greatly reducing The purchase and use cost of the winding machine-make REPOSAL's partners more competitive.

Research and development of horseshoe hollow cup motor coil and winding machine

Research and development of horseshoe hollow cup motor coil and winding machine

In recent years, China has paid more and more attention to hollow cup motor and automatic winding technology, and has made good progress and breakthroughs in the research and development and manufacturing of winding machine equipment.

One of the key reasons for the impact on the performance of the motor is the rotor coil in the motor, the rotor in the hollow cup motor has no iron core, small inertia, excellent functionality and a wide range of applications. In addition, in the research and development of coil winding equipment, the saddle-shaped coil arrangement is regular, and the utilization efficiency of magnets is high.

Compared with the old traditional motor with an iron core, the energy conversion efficiency is significantly higher than the latter, and the reaction speed will be much faster, and the hollow cup motor has high efficiency, fast response speed and stable performance. Because the hollow cup motor has no lag, additional electromagnetic interference is low, very high motor speed can be achieved, and the speed setting is sensitive at high speed, so it has relatively stable and stable performance. In addition, the energy density of the hollow cup motor is much greater than that of other motors, and the weight will be much less than that of an iron core motor with the same power.

Now according to the forming method of the coil, in the hollow cup motor coil, its production technology can be roughly divided into two process routes: winding production technology and one molding production technology.

Compared with the two methods, the first winding production technology is more complex, and the efficiency of winding the coil is relatively low. In order to improve the winding efficiency of coil production, the winding machine can be added to the production process of one molding. According to the hollow cup coil shape and winding method, the common hollow cup winding method can be divided into three kinds of parallel straight winding, saddle winding and oblique winding. The first parallel straight winding is generally used for hollow cup motor winding with relatively few turns. The last two are the two coil winding processes commonly used by the relatively advanced hollow cup motor manufacturers abroad.

Ring wrap tape machine

Ring wrap tape machine

We will now demonstrate the operation of the loop coil strapping machine again, take the product, put it in, and then buckle this storage ring. Note that the insulating tape must pass between the two blades of the scissors After the fixed storage coil count is reached, the toroidal coil wrapping machine will rely on it to cut the insulating tape. Then, one end of the tape can be passed through any position of the bearing evenly distributed on the storage ring. After passing through, take the head of the insulating tape and hold it with the head, and then press and start with the right hand. The entire loop coil is covered with insulating tape It's done automatically.

rogowski coil winding machine

rogowski coil winding machine