Operation video of belt loop coil winding machine-controller setting

Operation video of belt loop coil winding machine-controller setting

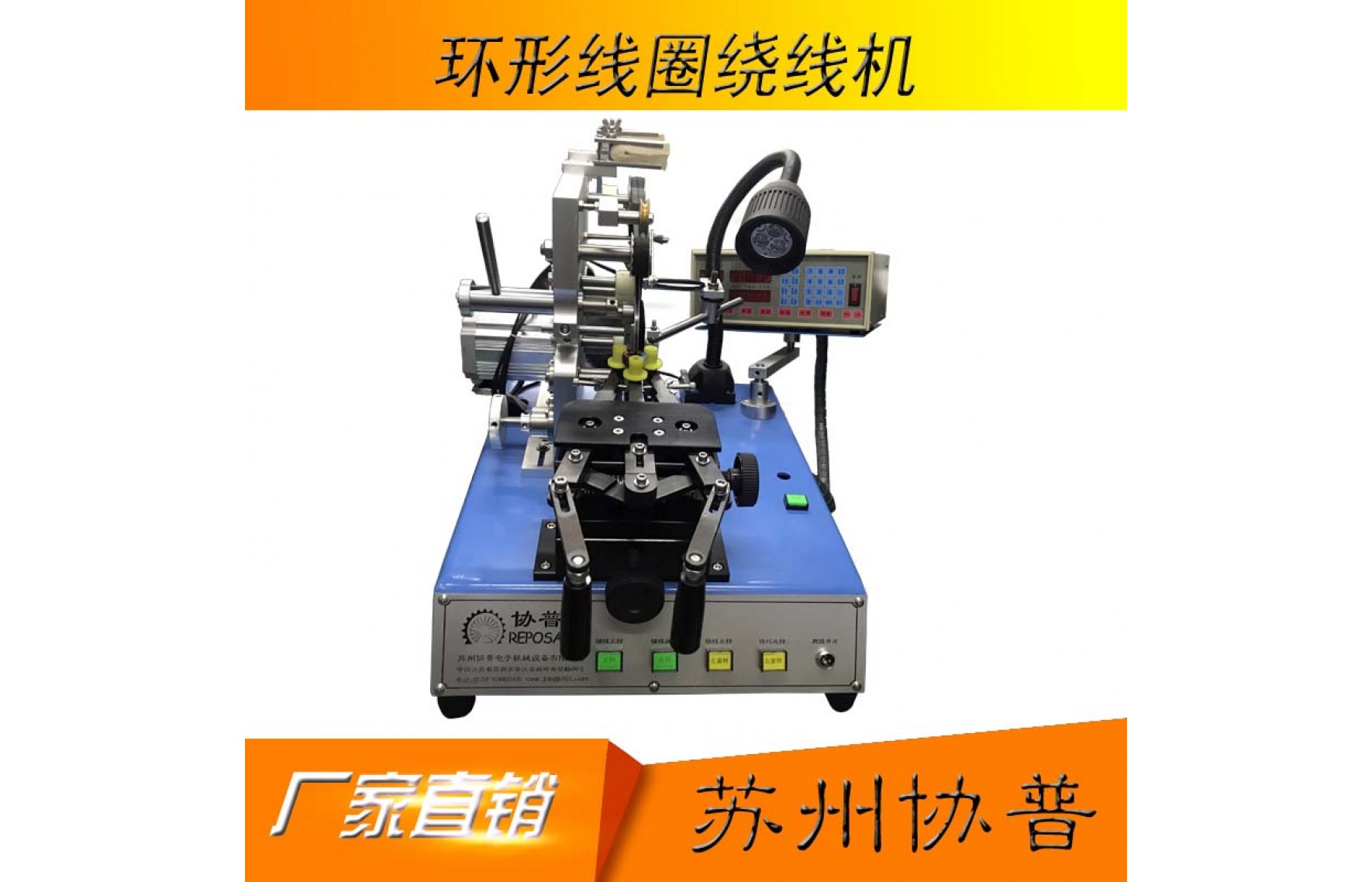

Now we focus on the use of the controller of the toroidal coil winding machine. The controller is very mature. It is divided into several functional areas. This one is the status area. For example, the indicator light before the standby character is on, which is standby. Status, the red light in front of the standby is on. For example, when we press Start, the running light will turn on, indicating that it is currently running. This is a status area.

This is a numeric parameter. When we want to set the parameters of the toroidal coil winding machine, for example, the parameters such as the diameter of the outer diameter and the diameter of the enameled wire, there is still a cable angle for the ring-shaped product. From this position to this position slowly, this involves a range. We use the winding angle and the cable angle to control the cable range on the controller interface, after the specified cable angle , He went back to the line, before and after the set winding angle and line angle.

The other is the speed. The high-speed and low-speed reference on the controller interface of the loop coil winding machine. The high-speed refers to the normal winding speed. The low-speed is the speed at the beginning and the end, and then the number of slow-down laps. Specify a specific number, such as slow speed, you need to specify a lap speed of one lap, two laps and three laps, according to your needs.

Here is a switch parameter area, such as the direction of the winding, such as the storage ring on this toroidal coil winding machine, we can let him turn clockwise or counterclockwise, and then the direction of the cable, the cable The direction is the process of winding the product. We can also let him turn clockwise or counterclockwise. This is the direction of the cable. Whether to start automatically between different programs, this can also be set.

This is an editing area on this side, enter the numbers, here is an external switch interruption area, under normal circumstances, each coil loop coil requires at least two procedures, the previous program is used to enamelled wire Import the storage ring, the latter program or multiple programs will wind the enameled wire imported into the storage ring and wind it onto the product. For example, this product, the product just demonstrated in the video, he also has two programs, the first program is 5. The program number we assigned to him is 5, and the second program is 6. We jumped through program 5 and jumped to program 6 through this jump, and the action of this product program 5 was to complete the storage line. The movement from the spool storage to the storage ring. 6 is to complete the movement of the enameled wire from the storage line to the product.

So how do we specify the number of this different program, for example, a product requires a storage process and a winding process, our ring coil winding machine, which can provide 1000 such programs, we define the start Step 1, then define the end step 2. At this time, we set the steps and then press the input, then all our settings will jump between 1 and 2, for example, the first program is the outer diameter of 30, pay attention to the decimal point here. Second, the outer diameter and inner diameter of the wire storage program and the winding program are the same, we copied it, and then the inner diameter is 20, we also copied it. In the wire storage process, we do not need to set the wire enameled wire Diameter, because our cable does not need to run, but we need to set it in the winding process, for example, 0.9, then we should pay attention to this place, the total number of turns for the storage line, the total parameter refers to the enameled wire The length of the winding on the storage ring, for this toroidal coil winding machine, its unit length is 135 mm, which means that if your enameled wire unfolded length is 1350 mm, you should set it to 10 turns, One unit is 135 mm, and those 10 units are 1350 mm.

Second, relative to the winding process, this total number of turns refers to the number of turns of the enameled wire wound on the magnetic ring, which is the actual number of turns. For example, I want to wind around 80 times. For general products, the winding angle and the winding angle are both 0. After we let it wind around for a full turn, we do n’t need him to wind backwards and let him continue to the front. It is such a situation. Then we give him the speed, high speed, for example, 10, low speed 3, we need to return to the previous parameter setting and press the minus sign, we also set the high speed of the storage line to 10, and then the high speed of the bypass is 50%, This is a percentage. Then we set the low speed to 3 and the number of slow turns to 1, and pay special attention to the distinction between storage and winding. How to distinguish in the control system of the ring coil winding machine is distinguished by the keys in the switch parameter area . As soon as we set it in the program, it is in the current program. If we set it to be a wire storage action, then the light of the wire storage button is lit. If we want to set it as a winding process, we put This indicator can be turned off. After that, we press Enter and press Return, and our setting is completed.

Some introductions to the buttons, such as jump section, we jumped directly from the wire storage process to the winding process, and the jump section retreated, and it appeared when there were more processes, and then reset back to the initial state, the stop button is used When winding, let the machine stop. The start button starts with one press, pauses with two presses, and restarts with another press.

Then the left and right buttons are used to adjust my cable drive wheel. For example, when I press it, they are equivalent to the two yellow buttons in front of the toroidal coil winding machine. Then, when we test, sometimes we need to manually It is also possible to drive the storage ring. There are two keys here, too. Our storage ring can also be tested by turning the handle and turning the handle. This place is a counter, and whenever there is copper wire passing, when passing the laser amplifier, look at the passing amplifier, so that the loop coil winding machine controller will count.