Ring wrap tape machine

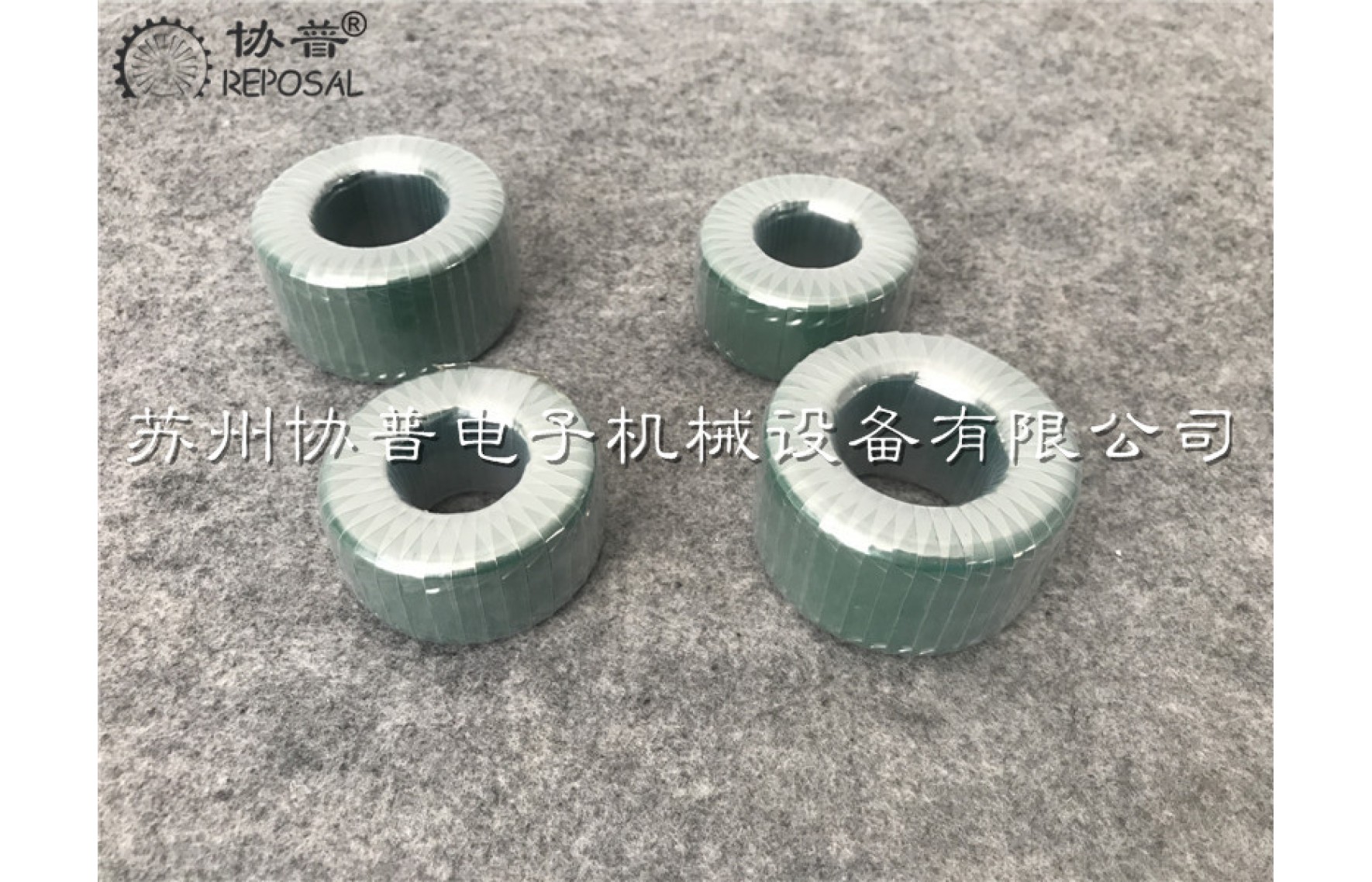

We will now demonstrate the operation of the loop coil strapping machine again, take the product, put it in, and then buckle this storage ring. Note that the insulating tape must pass between the two blades of the scissors After the fixed storage coil count is reached, the toroidal coil wrapping machine will rely on it to cut the insulating tape. Then, one end of the tape can be passed through any position of the bearing evenly distributed on the storage ring. After passing through, take the head of the insulating tape and hold it with the head, and then press and start with the right hand. The entire loop coil is covered with insulating tape It's done automatically.

Related Post

REPOSAL® successfully developed an ultra-precision flow tube metering heating wire winding machine

On August 6, the first ultra-precision flow tube metering heating wire winding machine independently developed by Suzhou REPOSAL® Electronic Mechanical Equipment Co., Ltd. successfully completed the test, and the performance of each index reached the level of the industry in advanced foreign countries.

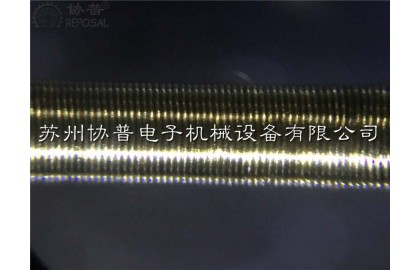

At present, the ultra-precision flow tube, a metal tube with a diameter of 0.4mm, a wall thickness of 0.1mm, an inner diameter of 0.2mm, and a special metal wire of 0.03mm are wound. There are single-layer winding, double-layer winding, and double-layer butt-joining winding. Flow tube is required There is no deformation at both ends and the metal wires are arranged neatly. This process technology has been monopolized by foreign companies for a long time, and the price is high, which severely restricts the research and achievement of ultra-precision flow meters in China.

Ultra-precision flow tube metering heating wire winding machine is an important symbol of independent innovation ability. The research of this equipment has broken through many key technologies of precision winding technology and optimized the process and mechanical structure. In the next step, Suzhou REPOSAL Electronic Machinery Equipment Co., Ltd. will further optimize the design and production process, reduce the cost of the whole machine, make it better to market, and accelerate the application and industrialization of localized precision winding machines.

REPOSAL® Toroidal transformer Taping Machine Instructions

Toroidal transformer Taping Machine Instructions

Analysis of winding tension of loop winding machine

Analysis of winding tension of loop winding machine

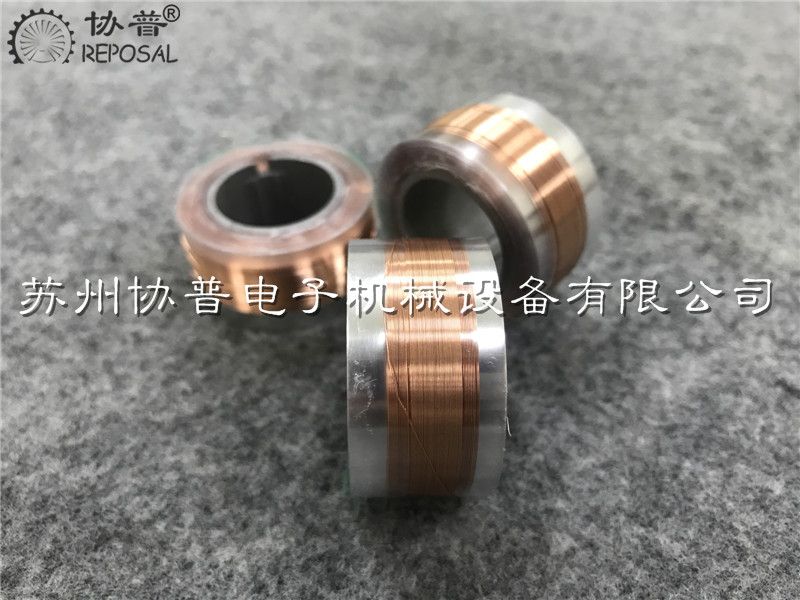

Toroidal winding machine-Toroidal coil winding machine-Enameled wire is wound radially on the closed toroidal structure (for details, please refer to the toroidal winding machine tutorial): With the rapid development of the domestic power industry, the demand for current transformer coils Increasingly, the development of current transformer coil winding equipment is imminent. In order to meet the needs of the market, we have developed a current transformer toroidal coil winding machine based on imported equipment. During the design and testing process, we found that, The key to the design of toroidal winding machine is the control of winding tension.

This automatic winding machine is composed of a frame, a pay-off mechanism, a winding head, a tape head, a clamping device, and a control system.

loop winding machine, automatic winding machine,

1, the working principle of toroidal winding machine

Firstly, the wires are evenly wound on the wire storage ring, and then the wires wound on the wire storage ring are wound on the skeleton by a shuttle. The skeleton is driven by the servo motor to rotate, so that the wires are evenly arranged on the skeleton when the wire is wound to a certain amount , And then wind the tape on the frame through the wire storage ring, and then wind it.

2, analysis of winding tension

Through our continuous practice, we have discovered that during the entire winding process, using appropriate force to wind the wire tightly on the skeleton is the key to the quality of the winding. Therefore, we will focus on the factors that affect the winding tension.

1. The grinding moment of the rotating part of the thread bobbin

2. The moment of inertia caused by the acceleration of the thread bobbin part (including the wire wrapped in the bobbin).

The main part of the frictional torque is generated by the tension mechanism, which prevents the wire shuttle from moving and tightens the wire to generate winding tension.

Due to the influence of the winding ring surface and its deviation from the center position in the winding gear, even if the winding is at a constant speed, the movement speed of the thread shuttle is small and uniform, which generates the moment of inertia caused by acceleration, which affects the winding tension.

The movement speed of the thread shuttle can be regarded as composed of two speeds: one is the speed Vo equal to the speed of the pulley on the winding gear, and the other is the speed at which the thread shuttle releases the amount of wire. The former is a constant, and the latter is calculated as follows ( see picture 1)

loop winding machine winding tension analysis 1

So in order to reduce the acceleration of the thread bobbin, it is required:

1. The frame profile H should be small, and the profile should be as close as possible to the center of the winding gear, that is, the value of 1 should be small.

2. The thread hook flat diameter R should be as small as possible.

3. The winding speed ω cannot be too high (this is in conflict with improving production efficiency).

The approximate curve of the speed Vx and acceleration а of the mountain thread shuttle is obtained by the graphical method, and the description is as follows (see Figure 2 and Figure 3):

loop winding machine winding tension analysis 2

1. When the small pulley on the winding gear is at the 0° position, the speed of the thread shuttle is equal to the speed of the small pulley V0, when the speed of the thread shuttle gradually increases from 0-60°, there is a positive acceleration at this time. =600-180`) when the thread shuttle moves at a constant speed, the speed is Vm>Vo. When а=180°~263°, the speed of the thread shuttle gradually decreases. At this time, there is a negative acceleration a = 263°. The speed of the thread shuttle is equal to the pulley speed V. When а=263°~345°, the speed of the thread shuttle continues to decrease. Small, that is, it is lower than V and has a negative acceleration. When а=345°, the speed of the thread shuttle is the minimum Vo, when а=345°~360°, the speed of the thread shuttle increases gradually and there is a positive acceleration.

2. When the winding gear rotates at a constant speed, the speed of the thread shuttle will be zero if it is small, so the friction tension mechanism always acts as a brake to keep the wire tensioned.

3. If Vp is the average linear velocity of the thread bobbin; Vo is the linear velocity of the pulley on the winding gear; L is the perimeter of the wire of the potentiometer, then

4. When the winding speed ω is not large: the wire bobbin diameter R is small, and the potentiometer profile size H is also small. When the profile is as close as possible to the center of the winding gear, the acceleration change is small and large, and the inertia caused by the acceleration The torque is much smaller

General debugging method of winding machine

General debugging method of winding machine

Some people look at the winding machine and feel a bit like a lathe, but in fact the winding machine has to wind a neat coil. Compared with the smoothness of the lathe, it is much more complicated, so we will find that the lathe has a long time ago The national standard has quantitative standards for its various indicators, but the winding quality of the winding machine has many condensing factors and it is difficult to quantify.

It is precisely because of the above reasons that at first I feel that the winding machine should be very easy to debug, but after the facts, I will be a little frustrated. Although the winding machine debugging is indeed more complicated than imagined, but if we master the basic laws After that, it's not difficult to practice more.

First of all, we must have a preliminary understanding of the structure of the winding machine, otherwise, we are not familiar with the structure of the winding machine, and there is no professional technical personnel training. Automatic debugging of the winding machine will be incompetent.

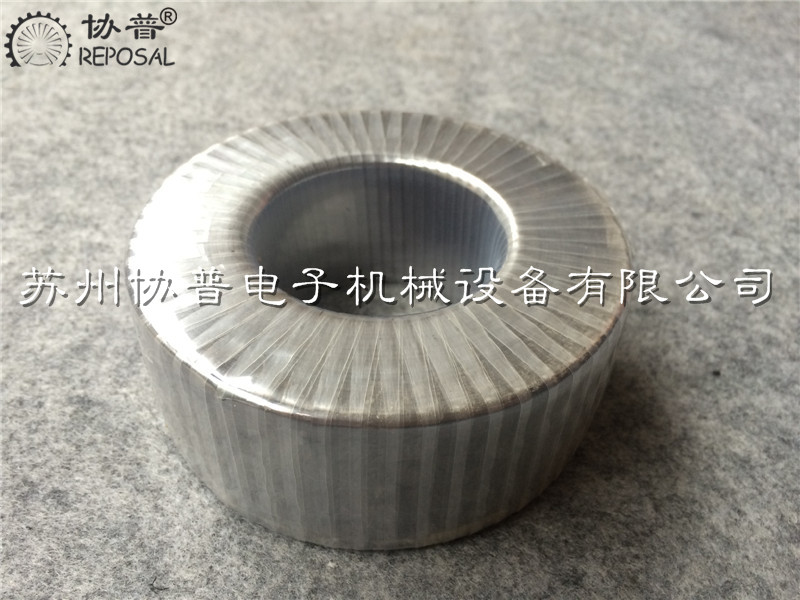

Gear type ring coil wrapping tape machine

Gear type ring coil wrapping tape machine

Compared with the belt-type loop coil tape belt machine, the gear-type loop coil tape belt machine has a larger processing range and more storage capacity. Our company's gear-type loop coil belt tape machine can be coated with polyester film and polymer Imide, cloth tape, glass fiber tape, etc.

We now open the clamping seat of the gear-type ring coil tape belt machine, the storage ring opens, and then put the product on, the storage ring buckles, the clamping seat merges, and then pay attention to the insulating tape must pass through the middle of the scissors, etc. Cut it off with scissors at once, and then go in from any bearing above the storage ring from the outside to fix the tape head behind the storage ring. The first few laps are slow because they are in storage. Ok, the product is finished, now we take it off, and then close the storage ring, the clamping seat is restored.