Research and development of horseshoe hollow cup motor coil and winding machine

Research and development of horseshoe hollow cup motor coil and winding machine

In recent years, China has paid more and more attention to hollow cup motor and automatic winding technology, and has made good progress and breakthroughs in the research and development and manufacturing of winding machine equipment.

One of the key reasons for the impact on the performance of the motor is the rotor coil in the motor, the rotor in the hollow cup motor has no iron core, small inertia, excellent functionality and a wide range of applications. In addition, in the research and development of coil winding equipment, the saddle-shaped coil arrangement is regular, and the utilization efficiency of magnets is high.

Compared with the old traditional motor with an iron core, the energy conversion efficiency is significantly higher than the latter, and the reaction speed will be much faster, and the hollow cup motor has high efficiency, fast response speed and stable performance. Because the hollow cup motor has no lag, additional electromagnetic interference is low, very high motor speed can be achieved, and the speed setting is sensitive at high speed, so it has relatively stable and stable performance. In addition, the energy density of the hollow cup motor is much greater than that of other motors, and the weight will be much less than that of an iron core motor with the same power.

Now according to the forming method of the coil, in the hollow cup motor coil, its production technology can be roughly divided into two process routes: winding production technology and one molding production technology.

Compared with the two methods, the first winding production technology is more complex, and the efficiency of winding the coil is relatively low. In order to improve the winding efficiency of coil production, the winding machine can be added to the production process of one molding. According to the hollow cup coil shape and winding method, the common hollow cup winding method can be divided into three kinds of parallel straight winding, saddle winding and oblique winding. The first parallel straight winding is generally used for hollow cup motor winding with relatively few turns. The last two are the two coil winding processes commonly used by the relatively advanced hollow cup motor manufacturers abroad.

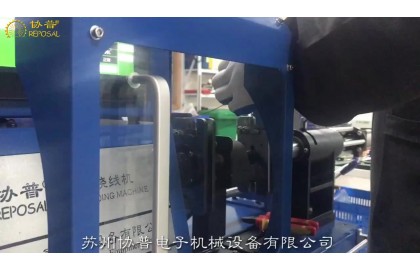

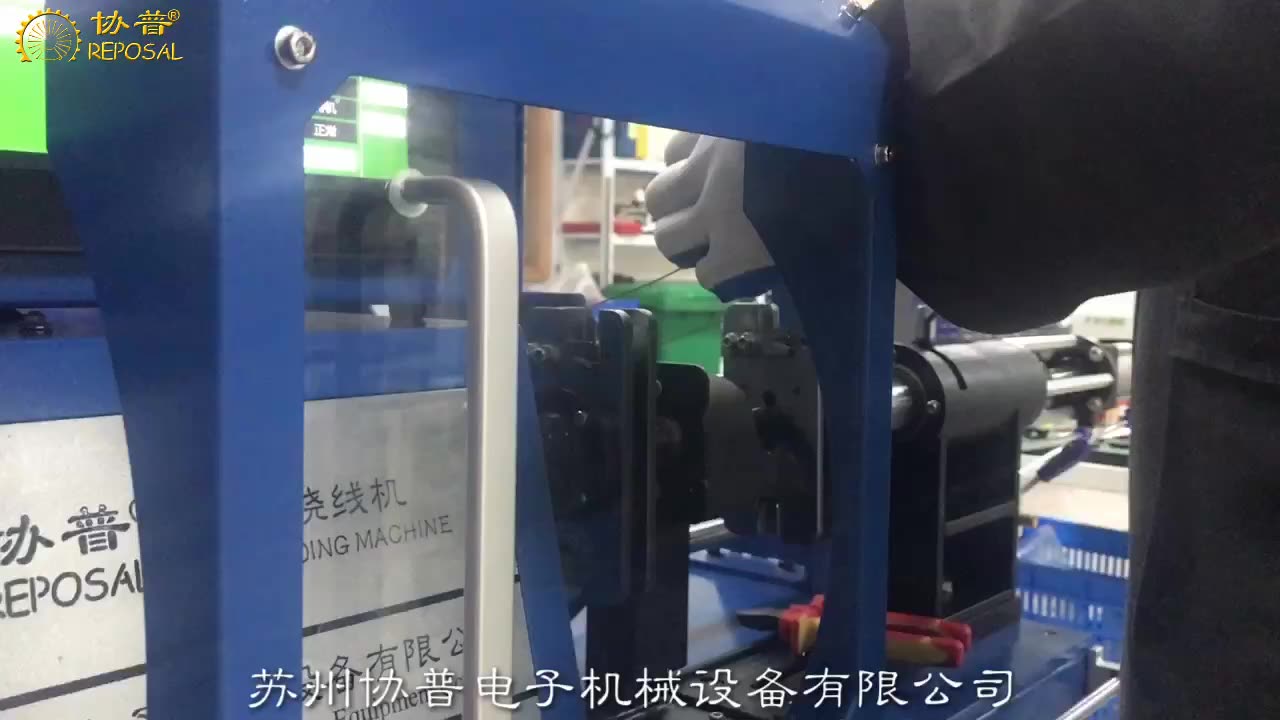

Because of the spread and wide application of new and efficient technologies, the quality quality and manufacturing output of hollow cup motors will face higher requirements and challenges. Due to these challenges and requirements, our analysis draws the conclusion that it is necessary to use the relatively important technology in the hollow cup motor, that is, focus on the structural design of the winding enamel wire coil and the coil winding process, develop and manufacture the saddle-shaped hollow cup coil automatic precision winding machine, break free of the two key constraints of the winding coil design and production. In order to improve the performance of the coil manufacturing and the efficiency and stability of the winding machine, it provides reliable technical and hardware support for the preparation of high performance hollow cup motor coil

Through the research and development of hollow cup coil winding machine, we can fill the shortage of precision winding machine in the domestic market, so as to achieve the purpose of improving quality while reducing cost and increasing efficiency in the production of high-quality hollow horse coil coil, further promote the development of hollow cup coil motor, and enhance the competitive advantage of hollow cup motor localization. In other aspects, the development of the hollow cup coil motor industry, in turn, can also promote the rapid development of mechanical and electrical products, which has realistic and important significance for the development of the winding machine industry.

Compared with the inclined wound coil, the wound saddle coil has better characteristics.

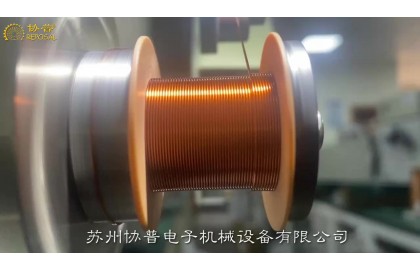

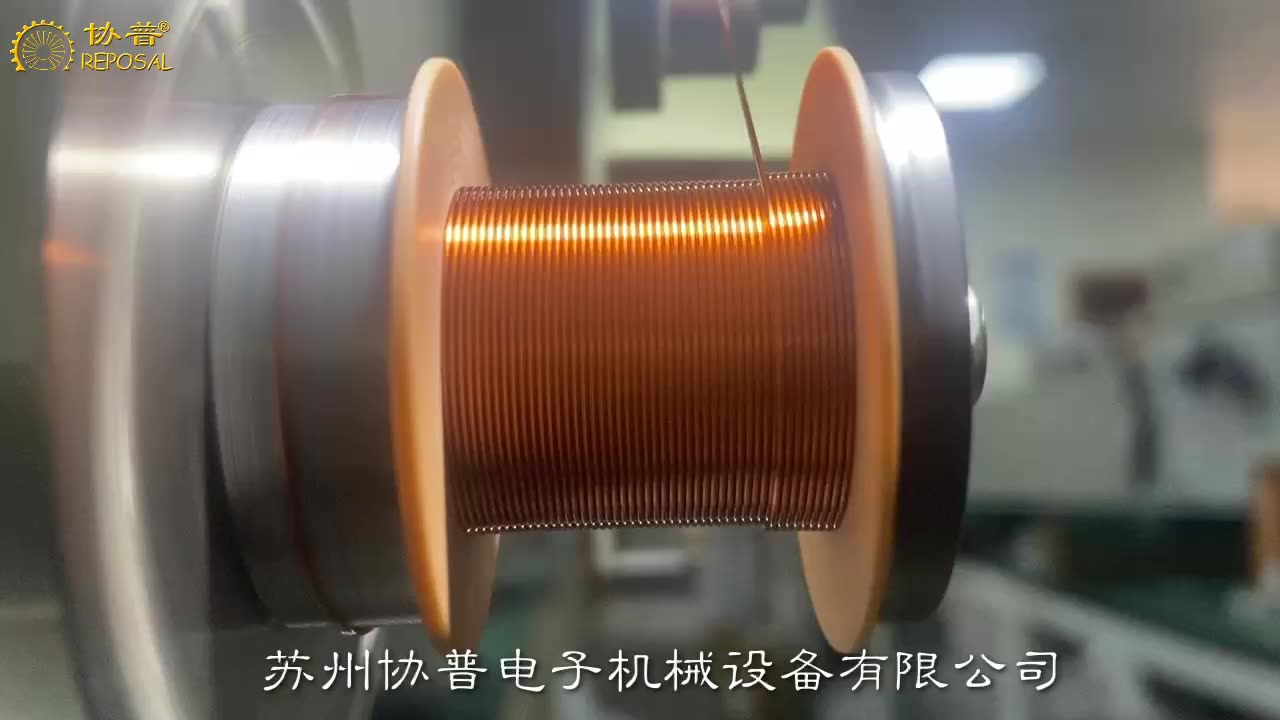

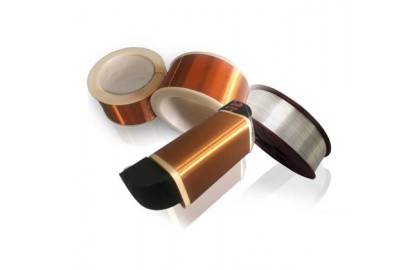

The winding of saddle-shaped hollow cup coil has a relatively regular winding geometry, and the enamelled wires are arranged neatly. Because of the existence of the enamel coating, the enameled wires do not interfere with each other in space. At both ends of the coil, the probability of their overlapping is relatively low, and the winding thickness of the coil winding is therefore controlled to be relatively small. Less finished air makes it easy to install at the same time can reduce material costs, can greatly improve the applicability.

On the motor with high power density, in order to effectively reduce the magnetic gap and increase the length of the cutting magnetic field, the saddle-shaped enamelled wire winding method is used, and the magnetic force line is successfully cut under the same circumstances. In this way, the enamelled wire used in the saddle-shaped winding coil actually uses less than the inclined winding coil, so the total length of the enamelled wire will be less. Therefore, the internal resistance of the motor coil is small.

Therefore, based on the above analysis, we can see that the two ends of the coil wound by the saddle-shaped coil winding method are thinner than the middle, and this coil shape makes the magnetic gap of the coil magnetic field smaller and can make full use of the stator magnetism. Moreover, for motors with the same power, the utilization rate of permanent magnet performance using the saddle-shaped coil winding method is higher, so the requirements for permanent magnets are relatively small, and it is easier to meet the output power of the motor at a low cost and high efficiency. Simply put, the same magnet is more efficient to use.

In addition, in the winding equipment used in the winding process, the inclined winding coil appeared earlier, so the technology is more mature, but the saddle-shaped coil winding because the winding process is relatively complex, so the research and development of the market started late, mature winding machine is relatively rare, and the company has studied the saddle-shaped coil winding for many years, has achieved excellent results, in this aspect of the technology is more mature.