The advantages of Type R transformer and the status quo of type R transformer winding machine

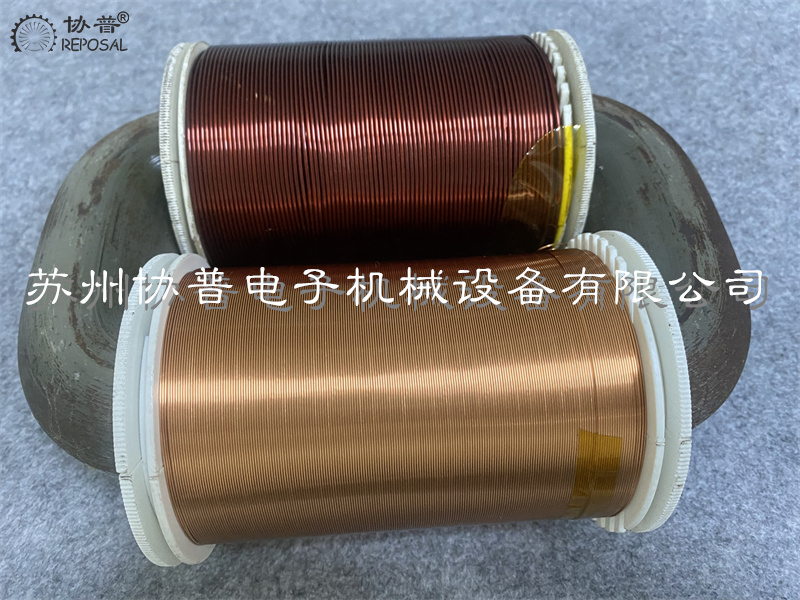

R-Core

transformers, when they first appeared, really made people bright. Its iron

core is made of high-quality cold-rolled silicon steel strip, which has been

delicately manufactured to form a unique waist circle, and the cross-section

shows a full circle, which can be made in one go without cutting. Of course,

this of course is not only a unique process, but the design will give the type

2 transformer a series of interesting advantages. Below we explore these

advantages in detail and make a comparison with other types of transformers.

Let's first talk about a feature of type r transformers. The core of the R-type transformer is a rectangle, and because the whole silicon steel sheet is converted into an iron core, its cross-section is actually circular. Compact shape design: The appearance design of the R-type transformer is quite simple, and the typical standard core has the characteristics of thin, small and light. This compact design means that the R-type transformer performs well in terms of space occupancy, making it particularly suitable for applications with space constraints.

The

R-type transformer has a very small magnetic leakage: due to the uniform

arrangement of its coils, the magnetic leakage is very small, and the magnetic

gap has little effect on it. The total flux of magnetic flux leakage is reduced

to a very low degree, which allows the two-star transformer to work even in

close proximity to other sensitive equipment without interfering with other

sensitive equipment.

Type

R transformer, its two winding arrangement is very uniform. The coil winding of

the Type R transformer is carefully designed to ensure a balanced distribution

of current inside the coil. This helps to reduce resistance losses and improve

efficiency.

In

addition, there is a particularly different advantage relative to the ring

transformer is the R-type transformer, its two windings, it is wound on the

skeleton, and it is a double-layer skeleton cladding structure, so its

insulation performance is particularly good, and the ring transformer, its coil

is actually wound on the iron core above, in the actual process, the iron core

above it, it will wrap insulation film, However, the thickness of the

insulation film is relatively small, so its insulation strength cannot be

compared with this R-type transformer. So this means that R-Core transformers

can operate safely in high-voltage environments and are more reliable.

In

addition, it has another feature, that is, its size structure will be

relatively compact, and its dimensions in the xyz three directions are

different, so it can be installed in a small space according to the needs of

many different ways ah, can be installed horizontally, sideways and

longitudinal installation, which provides a lot of options for the installation

personnel. Make Type R transformers suitable for various spatial layouts.

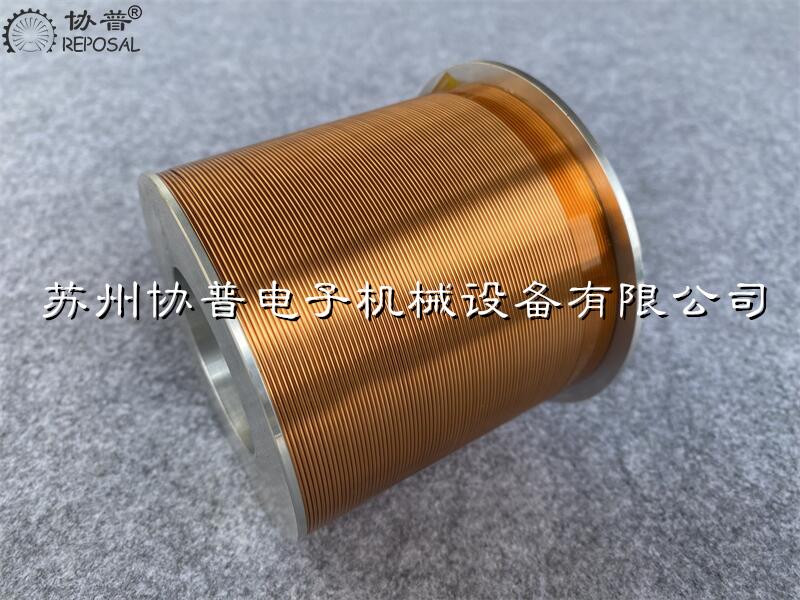

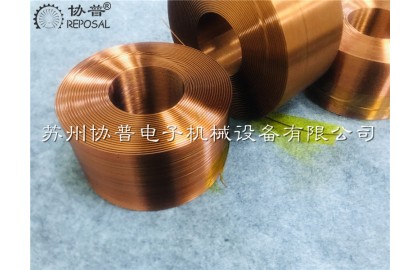

Another

point is that its special design of an iron core, the iron core of the R-type

transformer, it is wound into a rectangle from inside to outside, but it is a

high-quality cold rolled silicon steel strip from inside to outside that is the

whole width and narrowness, from fine to thick and then to fine, its

cross-section is actually round, it optimizes the magnetic flux path, greatly

reducing the iron loss. Improve the overall efficiency.

Low

temperature rise: Due to its compact design, the temperature rise of the R-type

transformer is relatively low. This helps extend the life of the equipment and

reduces the need for cooling systems. High efficiency: Low loss and optimized

design guarantee high efficiency of type R transformers. This is essential to

save energy and reduce operating costs.

Then

let's take a look at a feature of toroidal transformers.

The

core of a toroidal transformer consists of a cold-rolled silicon steel strip of

the same width wound in an involute pattern from the inside out into a ring.

Different windings are then wound in a radial fashion around this core ring. So

its structure is very simple. However, this structure will bring a relatively

large loss, so this feature will make the toroidal transformer power density

performance is relatively general.

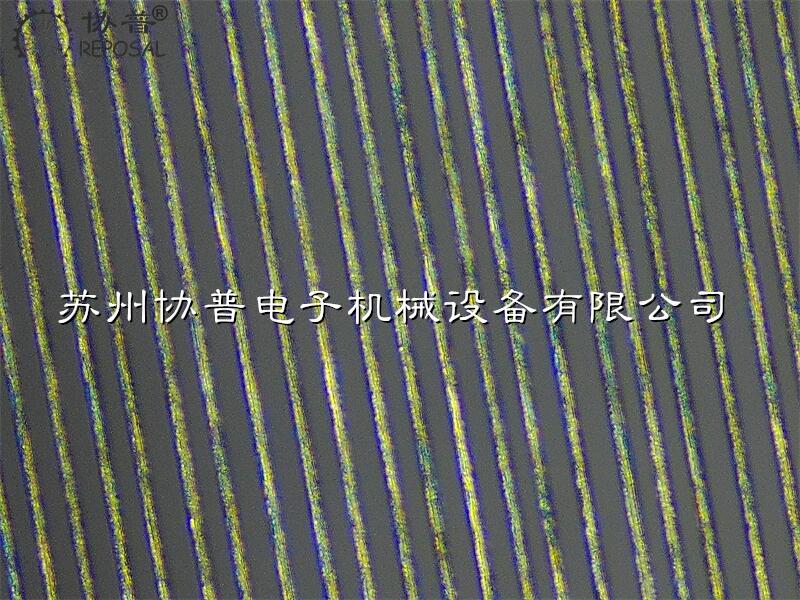

Another

is when the ring transformer is wound, it is the enamelled wire is wrapped

around the core ring in a radiating way, but its inner and outer circle, that

is, the circumference of the inner circle and the outer circle of the ring, it

is actually different, so in the actual process, there is no way to wind the

enamelled wire evenly. Specifically, when the enameled wire is wound on the

inside, it will accumulate more, and when it is wound on the outside, because

the circumference of the outer circle will be larger than the circumference of

the inner circle, so the winding of the enameled wire will be sparse, which

will directly lead to the local current density imbalance, increasing the

resistance loss of the coil.

Large

magnetic leakage: due to the toroidal transformer, its coil wiring supplier can

not be uniform, so its magnetic leakage is also more, and sometimes the

transformer needs to be placed in the metal mold to reduce the influence of

magnetic leakage, which will increase the complexity of manufacturing and

installation.

Usually

when we manufacture a ring transformer, its insulation layer is wrapped in a

layer of insulation film on the ring core, it is no skeleton, so its insulation

performance will be much worse than the double-skeleton R-type transformer,

which makes it difficult to meet the safety standards in high voltage

environments.

And

another point is that when it is installed, because its shape is circular, that

is to say, when it is installed, the length and width must be equal, and then

there is only one thickness difference, which is relatively speaking, the

choice in space use will be less, so generally speaking, it is relative to

R-type transformer, it needs more installation space.

With

a more detailed understanding, we can better understand the advantages of Type

R transformers over ring transformers, especially in terms of efficiency, space

utilization, insulation performance and flexibility. These factors will have a

significant impact on different applications, and choosing the right type of

transformer is crucial to the performance of the power system.

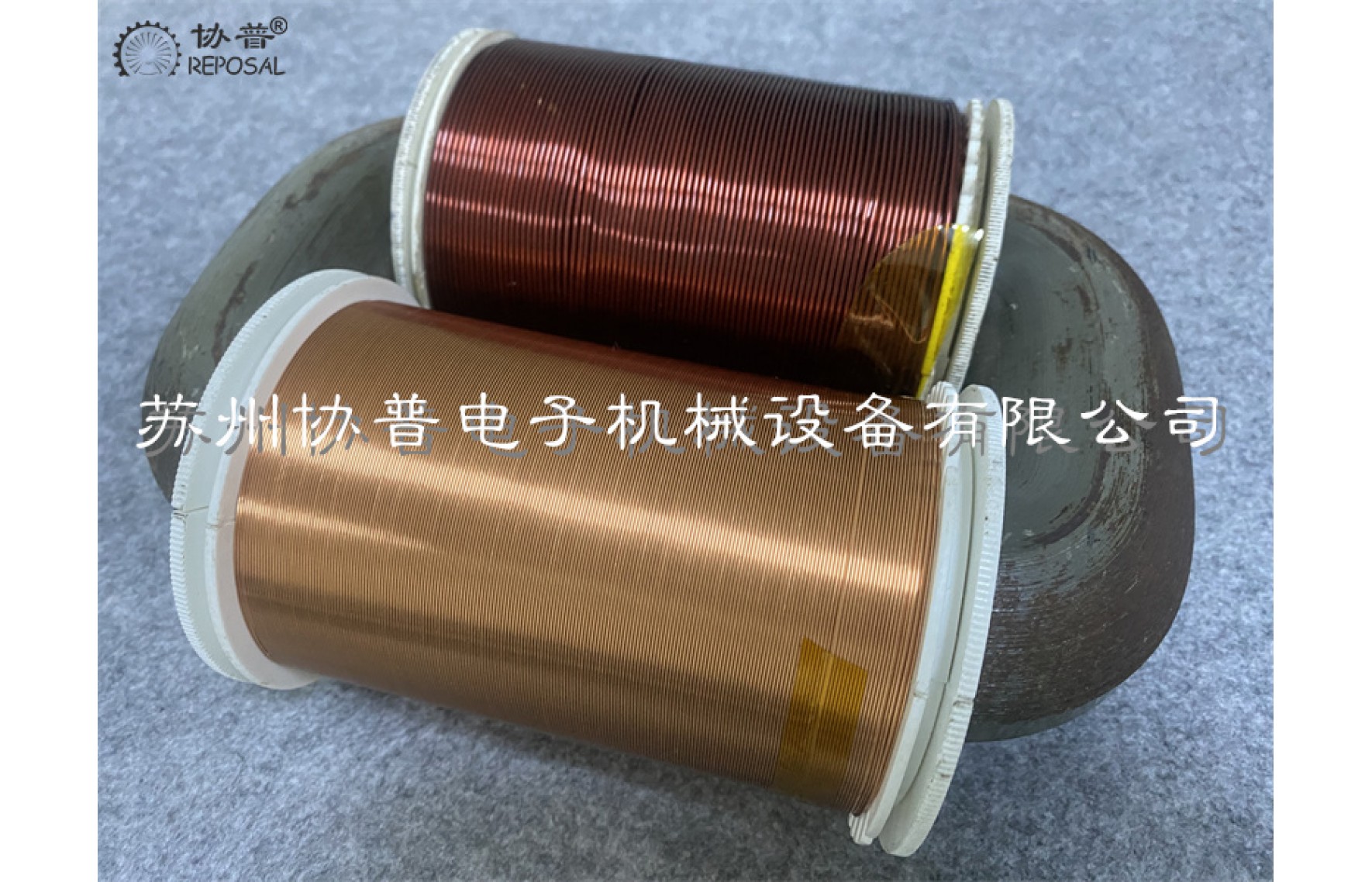

R-Core

transformers are widely used in a variety of electronic equipment, including

monitors, printers, computer terminals, photocopiers, fax machines, satellite

broadcast receivers, hi-Fi loudspeakers, measuring and testing equipment, power

equipment, flow metering equipment, medical electronic equipment, financial

equipment, industrial equipment, elevator lifts, signal equipment and so on.

The use of R-type transformer can greatly improve the quality and efficiency of

the product.

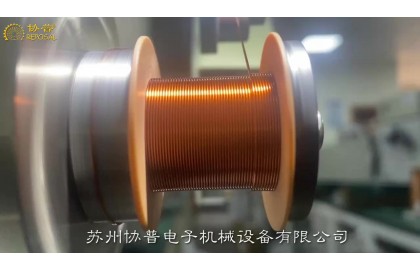

Although

R type transformer is widely used, but in fact the production of manufacturers

are not many, the reason is limited by the R-Core transformer winding machine,

so far, there are many R-Core transformer winding machine is the principle of

manual wiring, so its winding production efficiency is relatively low, Up to

now, many factories are using manual winding in the winding of R-shaped

transformers.

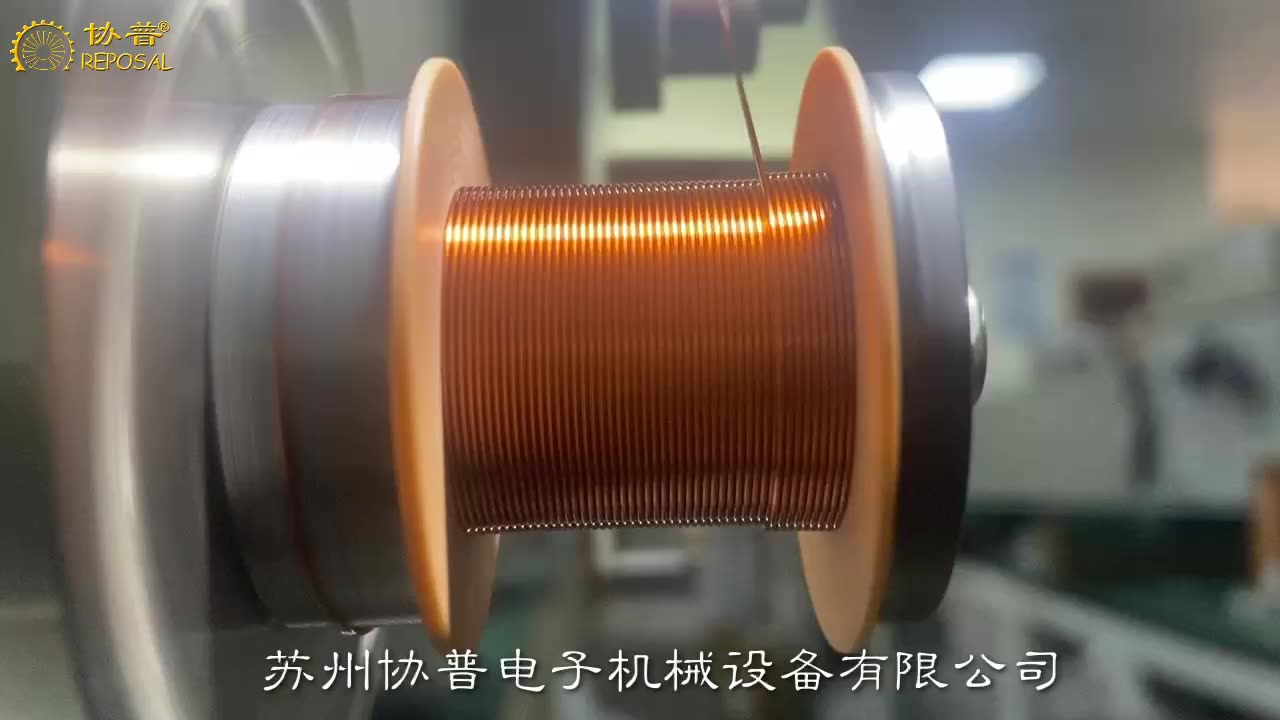

In response to this situation, we have launched an automatic R-Core transformer winding machine with high precision, complete functions, easy to use, stable and cost advantages, which has been widely recognized by customers since its launch. Our R type transformer winders have the following features:

1.

R-Core transformer winding machine special controller, high precision, stable and

reliable, easy to operate, computer (single chip microcomputer) control, full

key operation, working state digital display.

2.

1000 sets of process data can be stored and called, and it has the function of

button and foot start and stop, and the speed can be increased and decreased

during the winding process.

3. Handle built-in start-stop switch, which can improve efficiency, especially convenient for debugging.

4.

The configuration of a first-line brand laser amplifier, long life, high

precision, low failure rate, stable and reliable counting, laser amplifier

installation structure optimization, can be far away from the coil skeleton end

face accurate and reliable detection of the number of turns, fundamentally

solve the probe collision roller and skeleton movement brought about by the

count unreliable problem.

5.

R-Core transformer winding machine press wheel adopts step bearing design,

which can effectively control the axial movement of the skeleton in the

rotation process.

6,

the controller has complete functions: abnormal alarm function, such as

overload, reverse wiring direction, speeding and so on.

7.

Linear acceleration and deceleration function can be set at the beginning and

end of winding, which can eliminate the sudden acceleration and deceleration

effect and avoid disorderly or broken lines.