REPOSAL® machine research on tension control of transformer winding machine

In modern society,

electricity is like a surging torrent, injecting strong impetus into our life

and production. With the rapid development of China's science and technology

and economy, the demand for electricity is increasing day by day, and the

demand for transmission and distribution transformers, as an important

cornerstone of the power system, is also rising.

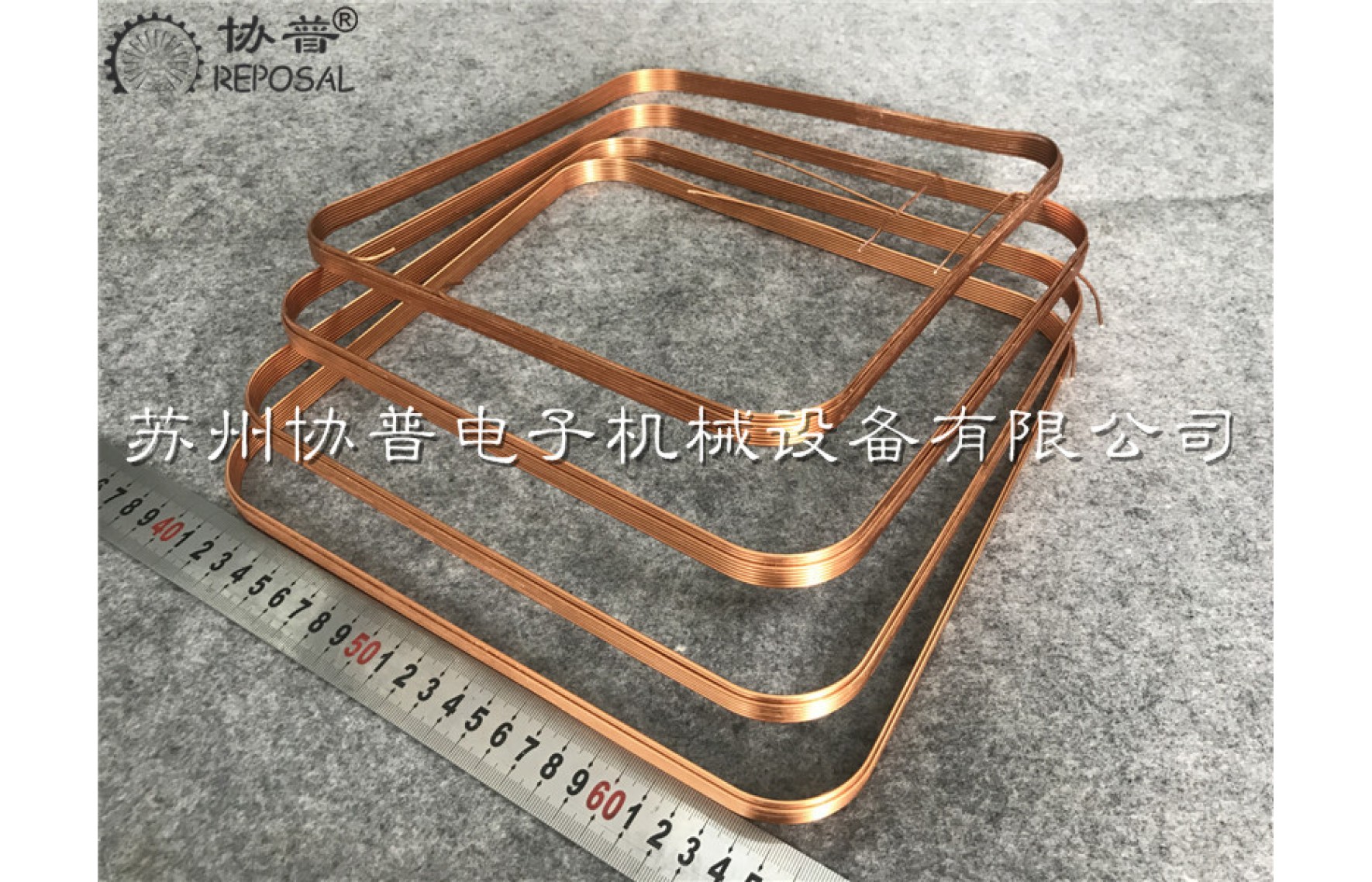

The transformer is

the "heart" of the power system, and the winding coil inside it is a

key component of this "heart". The winding quality of the enameled

wire and insulating tape in the winding coil directly determines the

reliability of the transformer. The quality of this winding depends to a large

extent on the performance of the transformer winding machine.

With the sharp

rise in demand for transformers, the performance requirements for transformer

winding machines are becoming more and more demanding. A high-performance

transformer winding machine must not only meet the requirements of safety,

intelligence and high efficiency, but also have high-stability hardware,

easy-to-use software and excellent tension control.

However, at

present, the development of China's transformer winding machine industry is

still facing many challenges. The level of intelligence is relatively low, the

stability needs to be improved, and most of the high-end equipment relies on

imports, and the price is high.

REPOSAL® machine

is well aware of these challenges and has been working hard to improve the

performance and quality of its products. It continues to increase R&D

investment, is committed to improving the intelligent level and stability of

the winding machine, and strives to contribute to the development of the

industry.

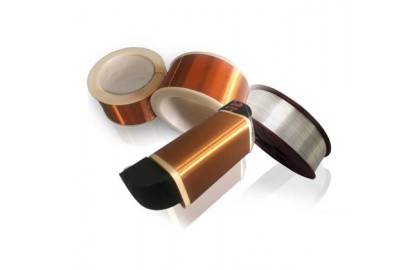

When the

transformer winding machine is working, its coil is usually metal wire and

insulating paper, because they have a certain elasticity, the change of coil

conveying speed or roll radius will lead to the change of winding tension. For

example, in the winding and unwinding process, if the angular velocity of the

roll is constant, the change in the radius of the coil will cause tension

fluctuations. If the tension is too large, the coil may become thinner or even

break; If the tension is too small, the material will be unevenly arranged or

wrinkled, which will affect the quality of the transformer winding coil.

Compared with

foreign countries, China's existing domestic transformer winding machine has

deficiencies in tension control. Its tension is usually generated by mechanical

friction, which is not stable enough, which can easily lead to problems such as

sparse arrangement of wires and insulating tapes, and out-of-tolerance of the

outer diameter of the coil. In addition, compared with developed countries in

Europe and the United States, there is a gap in the overall development level

of China's transformer winding machine in terms of processing quality and

production efficiency.

The specific

performance is as follows: First, the processes such as wiring and wiring,

adding insulation layers rely on manual operation, which is inefficient and unstable

in quality. Second, the motor frequently starts, stops and reverses during the

winding process, the tension fluctuates greatly, the coil winding is irregular,

and the quality is difficult to guarantee. Third, the mechanical structure of

the domestic winding machine is relatively simple, and it is not competent for

the winding task of complex coils.

The development of

foreign transformer winding machines is relatively mature. The T-600AH

automatic transformer winding machine from Trishul.Engineers in India can wind

wires and insulating tapes synchronously, with high precision, stable tension

and high efficiency. The EFECO 800 automatic winding machine from

Tuboly.Astronic AG in Switzerland is even more excellent, with high-speed,

high-precision winding and an intelligent cable routing system. The products of

companies such as MTM in Canada, LAE in Italy and UPI in Korea also have high

intelligence and stability.

In terms of

tension control research, many scholars have been exploring it in depth since the

90s of the last century. Bastogne T, Koc H and other scholars have pioneered

theoretical research and modeling simulation. Entering the 21st century, more

scholars are getting involved.

REPOSAL® machine

actively pays attention to the relevant research results at home and abroad,

and applies beneficial theories and technologies to the improvement of its own

products.

The winding

electronically controlled tracking system proposed by Mahawan B et al. in 2001

can still realize the trajectory tracking control of equipment under large

interference. In 2008, Wen P et al. designed a tension control scheme that

allowed the winding speed to be changed under a certain tension fluctuation

while maintaining quality. In 2010, Ponsart J C et al. applied the observer

theory to a transformer winding machine to improve the accuracy of tension

control. In 2017, Mahesh Ghate et al. optimized the tension system for a

specific winding machine and showed good robustness. In 2020, Ma Quanjin et al.

designed a dual-PID tension control system to address the tension fluctuation

problem in a 3-axis fiber winding machine applied with filament winding

technology.

Since the 70s of

the last century, China has begun to develop transformer winding machines, and

has achieved certain results through imitation and the efforts of scholars.

However, due to the monopoly of foreign core technologies, there is still a gap

with foreign countries, especially in terms of manufacturing processes and

control schemes.

At present, the

domestic transformer winding machine is mainly in the semi-automatic stage. For

example, F. of Dongguan Zongheng Electromechanical Technology Co., Ltd. TWloo

CXL transformer winding machine for small and medium-sized transformer coil

winding. The ZBR.800/1000/1200 multi-head automatic wiring winding machine of

Jiangxi Yibo Automation Equipment Co., Ltd. can realize automatic wire

arrangement.

REPOSAL® machine has been committed to promoting the

development of domestic transformer winding machine in the direction of full

automation and intelligence, and constantly optimizing its own manufacturing

process and control scheme.

However, there is still a breakthrough in the layout of

insulating tape and tension control in China, which greatly affects the quality

and production efficiency of the winding coil. Therefore, it is of great

significance to develop a control system that can automatically arrange wires

and insulating tapes with constant tension.

Tension control is a key technology for transformer

winding machine equipment. If the tension is too small, the wire or insulating

tape will slacken, accumulate and wrinkle; Excessive tension can cause it to

deform, stretch excessively, or even break. For transformer winding machines,

the tension control condition directly affects the compactness between the

layers of the winding wires.

At present, there are three main schemes of tension

control: manual, semi-automatic and fully automatic. The manual control needs

to be adjusted manually in stages, the semi-automatic control adjusts the

tension by detecting the change of the roll diameter, and the fully automatic

control is adjusted by directly measuring and feeding back the tension data by

the tension detector.

In the 80s of the last century, manual tension control

was mostly used in China, which was gradually replaced due to the increase in

demand. Since the beginning of this century, domestic scholars have conducted

in-depth research on the automatic tension control system for rewinding and

unwinding.

In 2005, Yang Tao and others from Tianjin Polytechnic

University used a PLC design scheme to accurately control the winding speed of

fine enameled wire. In 2010, Shi Yaoyao et al. studied the discontinuous coil

process and realized winding through the PID algorithm. In 2018, Zhiyong w et

al. established a constant tension control system for the problem of triaxial

fiber winding machine. In 2020, Song Chenliang et al. optimized the tension

adjustment effect of the winding machine through the pendulum tension

adjustment mechanism and the deformed PID control algorithm.

REPOSAL® machine has never stopped exploring tension

control solutions, and constantly tries to innovate to enhance the

competitiveness of products.

However, due to the complex structure of transformer

winding equipment and many influencing factors, the tension control system has

nonlinearity and coupling in different situations, which is still a difficult

point in equipment control. Constant tension control is very important to

ensure the quality of winding, so it is of practical significance to study the

constant tension control system suitable for industrial production.

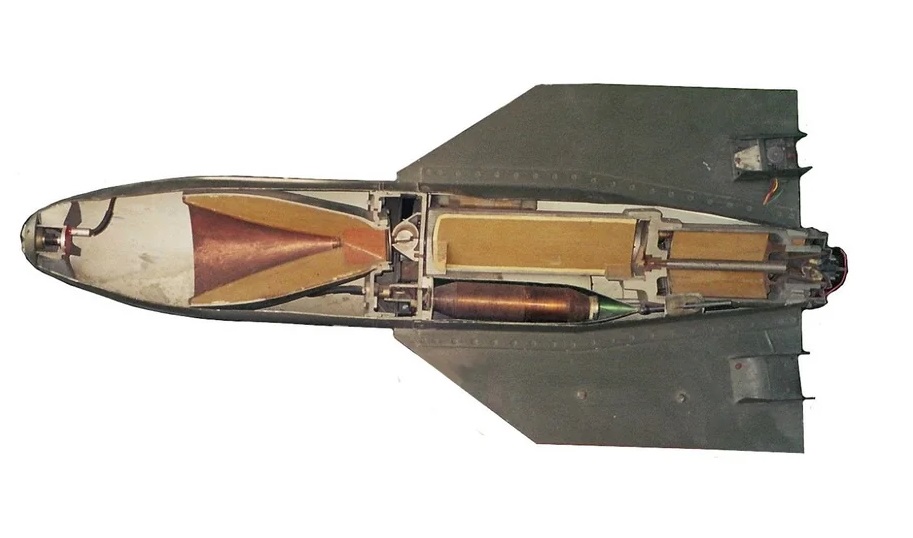

In the winding coil structure of distribution

transformer, insulating paper tapes need to be arranged between the wire

layers, so the transformer winding coils are usually wound in layers. The

winding process is more complicated, the pilot wire is unwound and sent to the

spindle mold base, during which the oscillating roller adjusts the tension and

speed, and the spindle motor drives the spindle winding. Then the insulating

tape is unwound and sent to the spindle mold base, and multiple coil rolls

cooperate to adjust the tension. Finally, a plurality of motors work together

to drive the spools and other spools for the first layer of winding and arrangement,

after the completion of the wire motor reversal, the pressure roller shears the

insulating paper, the glue sprayer glues, and then the next layer of winding.

Taking Switzerland EFECO 800 transformer winding machine

as an example, its mechanical structure mainly includes spindle mold base,

winding spindle, glue spraying machine, etc. The winding spindle includes a

spindle motor, a reducer, etc., which drives the spindle to rotate and the foot

switch controls the start and stop. The wire winding mechanism has pay-off

wheels, adjusting handwheels, etc., and the insulating tape winding mechanism

has tension feedback devices. The wiring mechanism is composed of a wire spool,

a wire trolley, etc., which can achieve accurate wire arrangement.

For transformer winding machines, the tension control

directly affects the compactness between the winding lines. In practice, the

machining accuracy and the performance of the sensing device will have an

impact on the tension control. For example, the change of reel diameter, the

start-stop and acceleration and deceleration of the reel, the accuracy of

equipment manufacturing and assembly, the forward and reverse rotation of the

motor, and the hardware performance.

There are three ways to test tension. Directly using the

tension sensor to measure, the operation is simple but the limitation is large;

Floating roller tension detection, the measuring device is flexible but the

accuracy is low; Floating roller/feedback composite tension detection, high

accuracy but complex method.

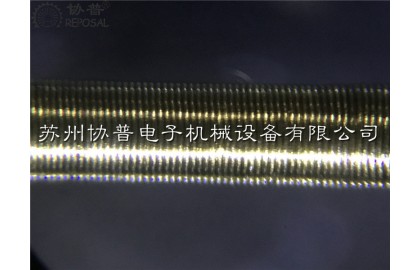

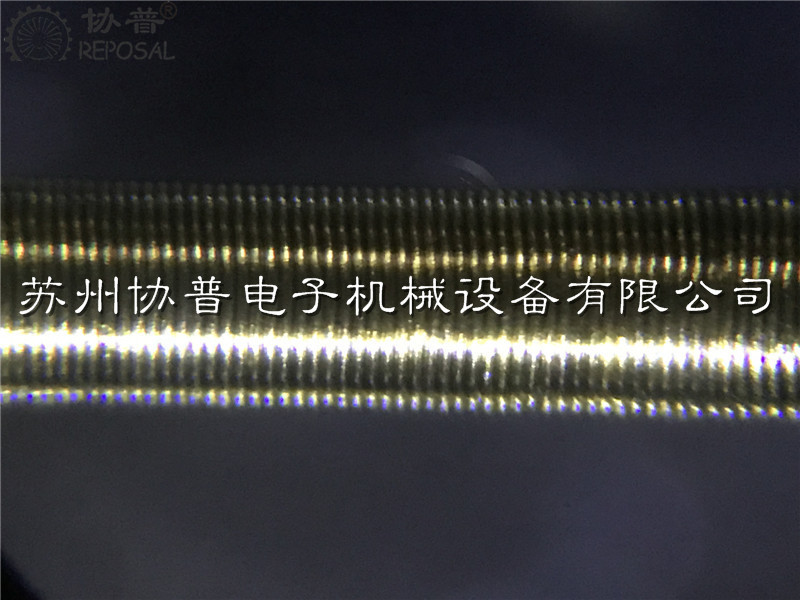

In the process of arranging the transformer winding

machine, the adjustment of the wiring mechanism and the winding position and

the control of the wiring angle are the key to ensure the compactness of the

winding wire.

The cable arrangement mechanism measures the angle

through the rotary encoder on the spindle and transmits the data to the

controller, and the controller drives the wire motor after processing to

realize the speed coupling of winding and wire arrangement.

In the actual winding, the tension of the wire and the

insulating tape should be kept constant and cooperate with the wire

arrangement. In the automatic wiring control scheme, the main controller

controls the motor unit to work together, the spindle and the wiring mechanism

cooperate with the layered winding, the encoder feeds back the data in real

time, and adjusts the speed of each axis according to the control algorithm to

ensure the accuracy of the wiring.

The angle of the cable is very important, too large or

too small will affect the effect of the line. When winding, the line is

adjusted according to the change in angle, the feed rate is brought in, and the

overall trajectory is followed. Since winding is carried out in layers, divided

into wire layers (odd layers) and insulating layers (even layers), the wire

laying process can be divided into multiple stages and cycles.

The automatic wiring of the transformer winding machine

has high requirements for the motor control algorithm, which requires the

coordinated operation of the motors of each shaft and the close cooperation of

the drive actuator to jointly complete the automatic winding and arrangement of

the transformer coil. The common multi-motor cooperative control structures

include parallel synchronous control, master-slave motor control,

cross-coupling collaborative control, adjacent cross-coupling control and

deviation coupling step control, each with its own advantages and

disadvantages.

In conclusion, transformer winding machines are very

important in the power field. Although China has made certain achievements in

this field, it still needs to make continuous efforts to strengthen independent

research and development, improve the technical level, narrow the gap with

foreign countries, promote the development of the industry, and contribute more

to the power industry. REPOSAL® machine will continue to uphold the spirit of

innovation and enterprising, and make unremitting efforts to improve the

overall level of China's transformer winding machine.