REPOSAL®successfully releases hot micro flowmeter winding machine

REPOSAL®successfully releases hot micro flowmeter winding machine

----------solve the problem of heat pipe coil winding process

Flowmeter is one of the commonly used instruments in industrial production, the most common such as all kinds of water meters in life, gear water meters, electromagnetic water meters, ultrasonic water meters, etc., according to the different industry applications, chemical, petroleum, pharmaceutical, food and other industries are also widely used, can measure the volume or quality of various fluids through the pipeline in a given time. Easy to measure in each fluid automation control.

However, in medical, aerospace, military and other fields, we may need to measure tiny fluid flows, and in microfluidic processes, micro-thermal flow meters are also necessary, which can measure very small fluid flows, thereby helping researchers control the flow of fluid in microfluidic devices and optimize device performance.

Another example is the flow control of pure oxygen fluid in the ventilator, the flow control of the medical dosage ratio, the flow equivalent is very small, and at the same time, it requires extremely high measurement accuracy, so the thermal micro-flow meter should appear according to demand.

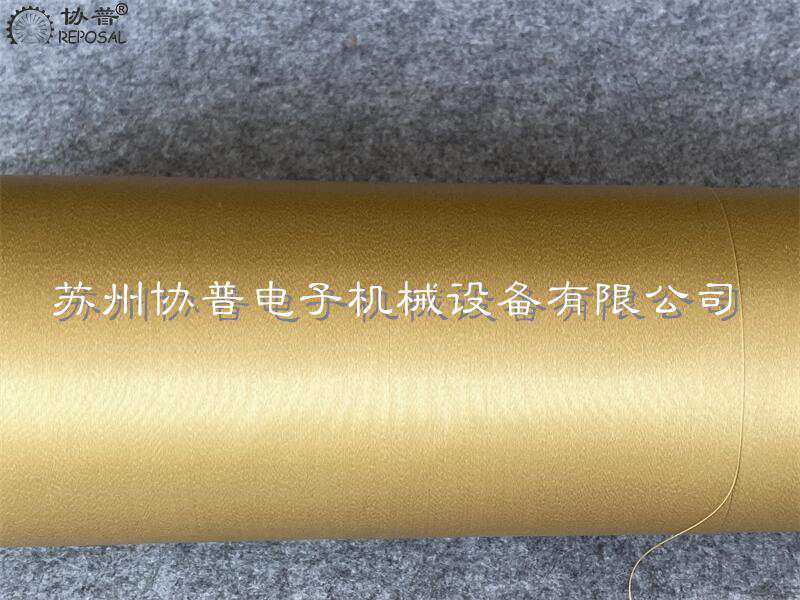

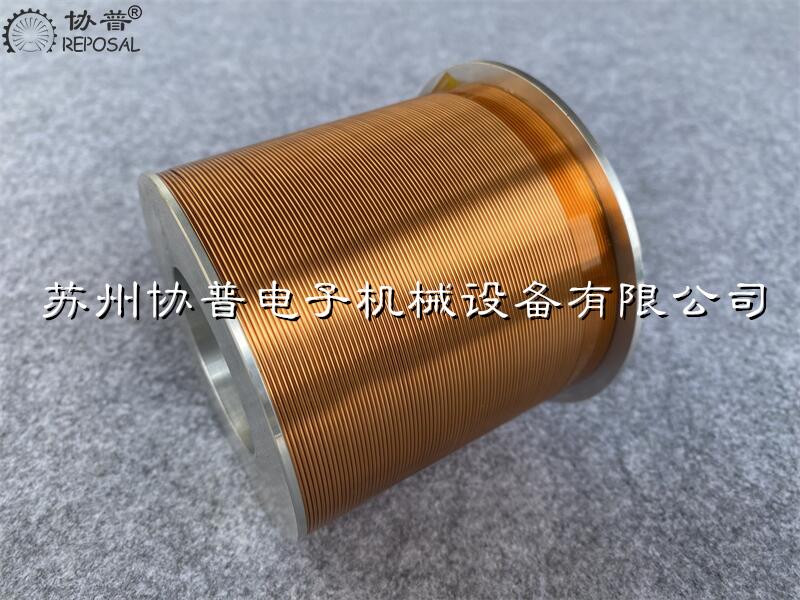

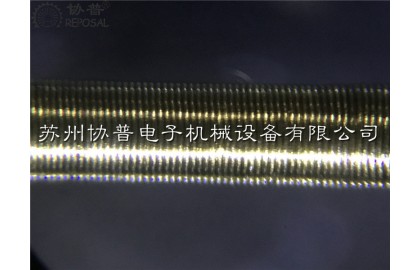

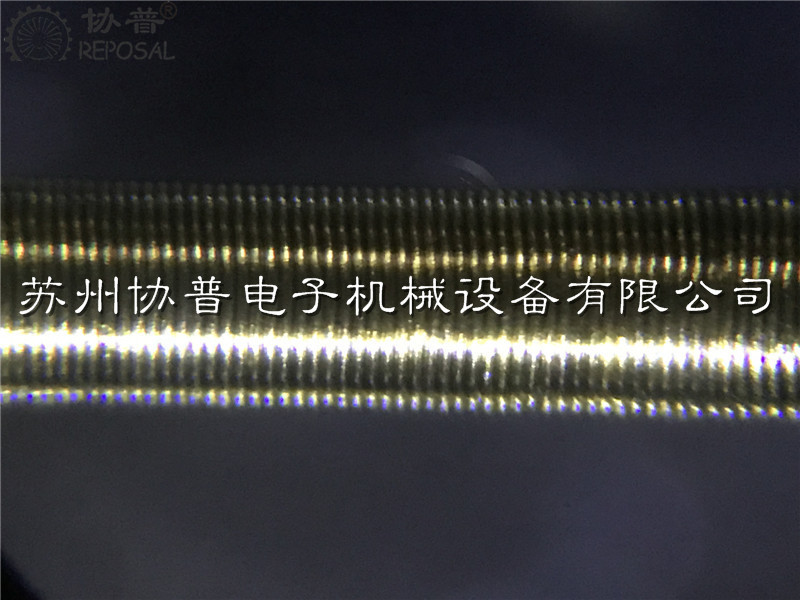

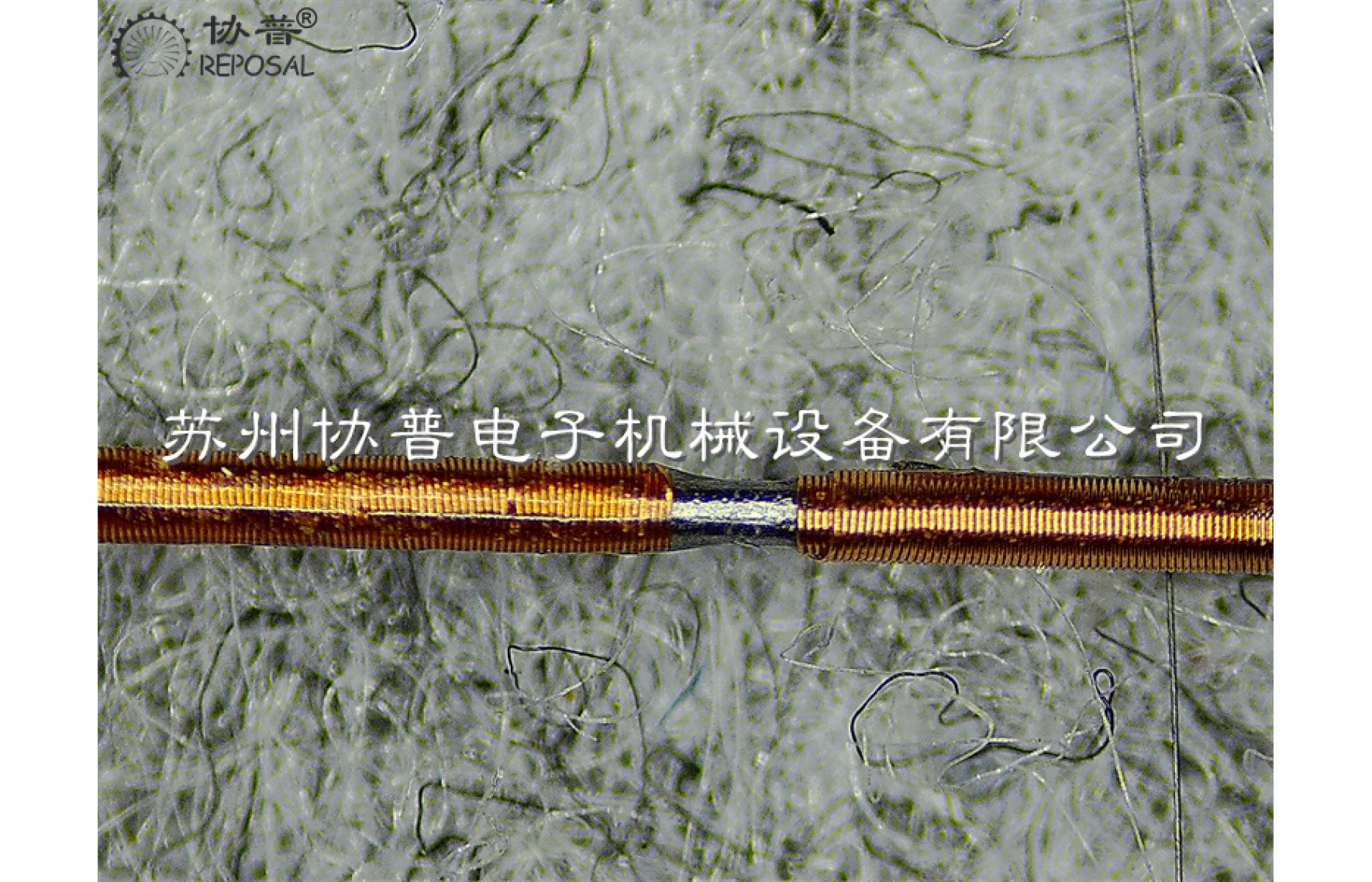

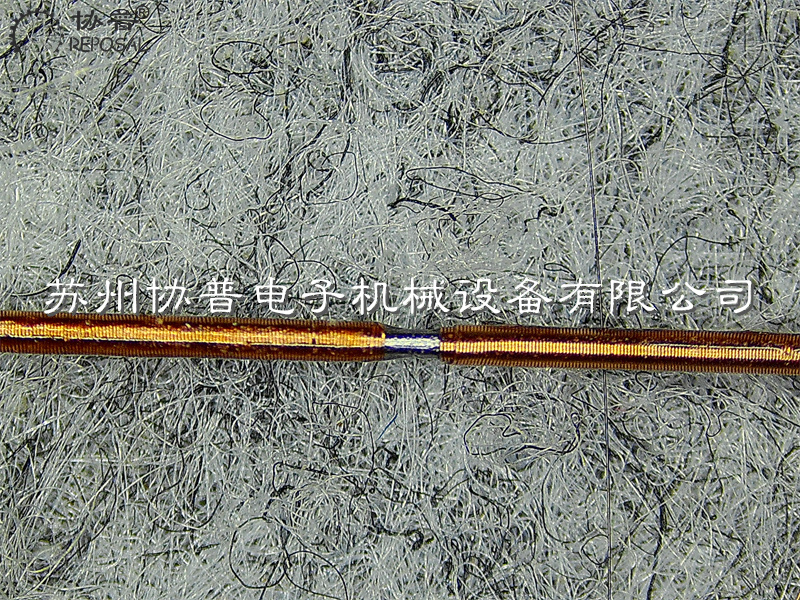

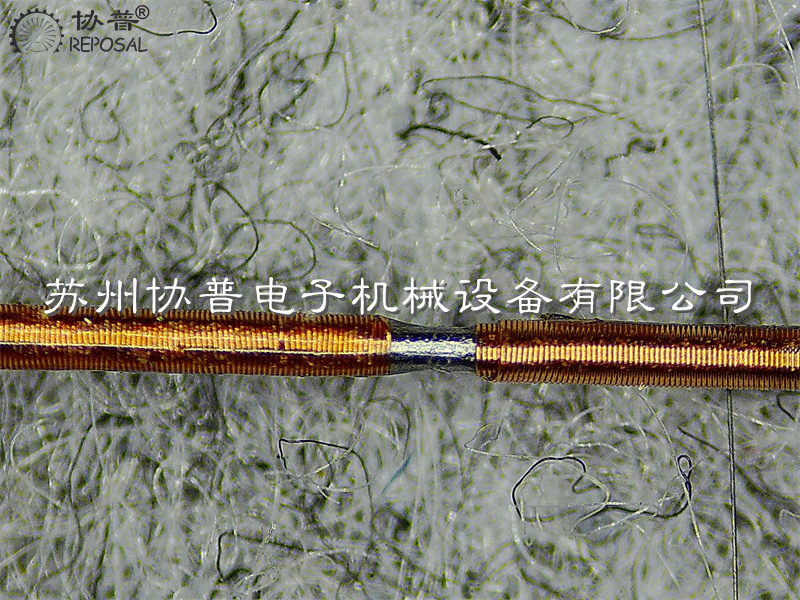

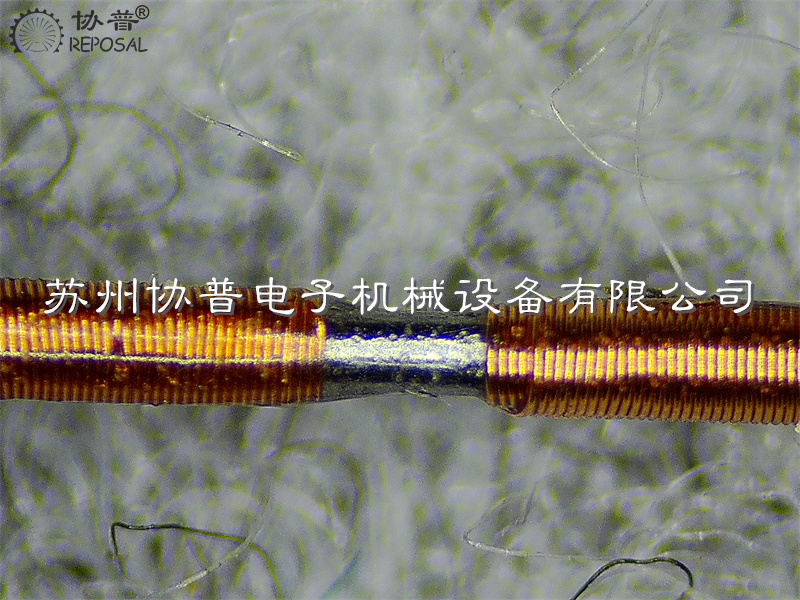

The thermal micro flowmeter is mainly made of the principle of capillary heat compensation. In the thermal micrometer, the fluid passes through a small pipe, and on the outer wall of the pipe, the thermal micrometer winding machine is used to wind a very small electric heating coil, which usually uses a fine platinum resistance wire, with a diameter between 0.02 and 0.05mm. When the fluid flows through the platinum resistance heating coil, the temperature of the fluid increases slightly. At this time, another set of platinum resistance coils wound by the thermal micro-flowmeter winding machine can sense a higher resistance, and the controller converts this resistance value into a flow value.

The diameter of the platinum resistance coil in the micrometer is very small, and the texture is fragile, and it will heat up after being energized. When the fluid passes through the capillary of the flowmeter, the flow will take away the heat of the platinum resistance coil wound by the hot micro-flowmeter winding machine, resulting in a decrease in the temperature of the platinum resistance coil. In order to keep the temperature of the platinum resistance coil stable, the micro flowmeter will provide a certain current according to the measurement needs to maintain the temperature of the hot wire at a constant operating temperature. By measuring the change in current provided to the hot wire, the mass flow rate of the fluid can be obtained.

Thermal micro flowmeter has many advantages, the main advantage is high accuracy, can measure the flow range of small small fluid, the accuracy can usually be within 1%. Moreover, it is small in size and can be easily designed into module units for convenient arrangement. It can also directly output electrical signals, and the communication with the data collector is convenient.

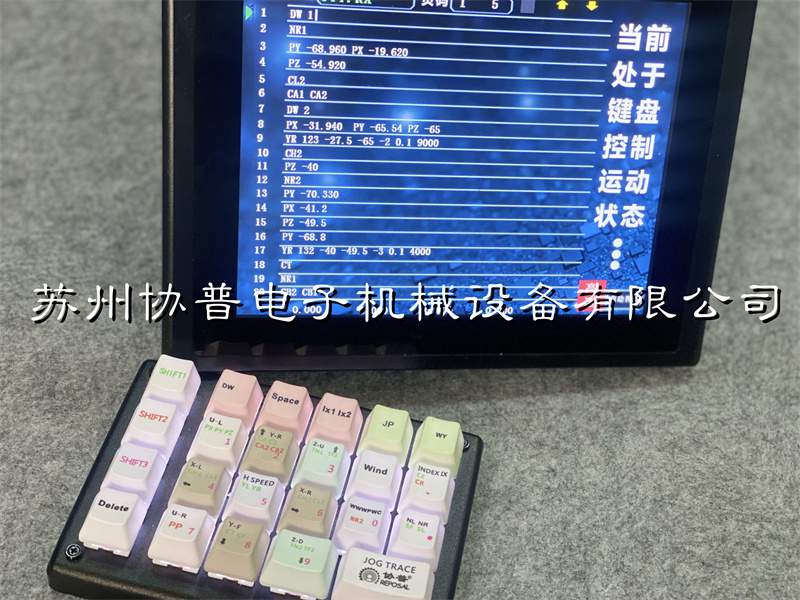

However, its manufacturing difficulty is high, especially the platinum resistance heating coil, the need for hot micro-flowmeter winding machine, in a very small diameter capillary wound diameter 0.02-0.05 platinum wire, the small diameter of the platinum wire itself is more fragile, the capillary also needs to overcome the radial displacement caused by the tension of the platinum wire during the winding process, and requires orderly arrangement. The tension is stable and the resistance is consistent, so the process is extremely difficult, and the current micro-precision winding technology of this hot micro flowmeter winding machine has been supported by sensor companies in Japan, the Netherlands and Germany for a long time.

The domestic precision winding mechanism manufacturing system from low-end to high-end, there are huge challenges, because there are shortcomings in the manufacturing equipment link, not only the problem of individual equipment such as hot micro flow meter winding machine, but the entire precision winding machine industry is lack of independent development conditions, the industry is keen to imitate foreign industry technology for a long time, and the user long-term superstition imported equipment, It is also one of the conditions for domestic winding machine enterprises to lack independent development, so the cost of domestic thermal micro-flow meters has been high.

Therefore, REPOSAL®, as a domestic technology company focusing on special precision winding, has paid attention to this field for many years, and was invited to domestic technology companies and research institutes in related fields to develop hot micro flowmeter winding machines on the agenda.

At present, the most advanced process of the hot micro flowmeter winding machine has been mastered by REPOSAL® is the capillary winding 0.02mm platinum wire with a diameter of 0.35, which is in a whole row state, and its process efficiency and winding program are also advanced compared with foreign peers. We have successfully developed a thermal micrometer winding machine, and domestic users do not have to superstitious about the advanced nature of imported thermal micrometer winding machines.

Domestic microflow sensor enterprises have developed for so many years, has formed a understanding with foreign winding machine suppliers, years of cooperation may be difficult to break instantaneously, it is also out of this consideration, ShEP from some subdivision characteristics of strong winding machine types, such as optical fiber winding machine, tripping titanium plate winding machine, scanning electron microscopy coil winding machine, polarization wire grid winding machine, Hot micro flow meter winding machine, looking for a breakthrough.

Of course, whether it is external or internal reasons, can reflect a problem, that is, China's precision winding machine industry does have a lot of room for progress, not the release of a winding machine can prove that domestic precision winding machine has risen.

At present, REPOSAL®'s thermal micro flowmeter winding machine is widely used in cardiopulmonary bypass, ventilators, blood gas analyzers and other medical equipment thermal micro sensors, but also used in the monitoring of vehicle exhaust emissions, aircraft fuel tank oil level monitoring, and engine fluid flow control and other automatic control fields.