REPOSAL® Toroidal transformer Taping Machine Instructions

Toroidal transformer Taping Machine Instructions

Related Post

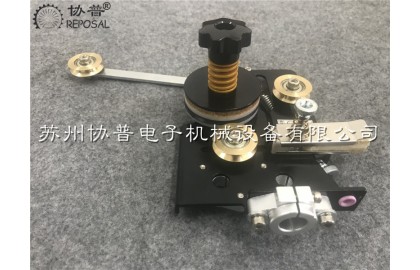

Instructions for use of standard winding machine tensioner

Instructions for use of standard winding machine tensioner

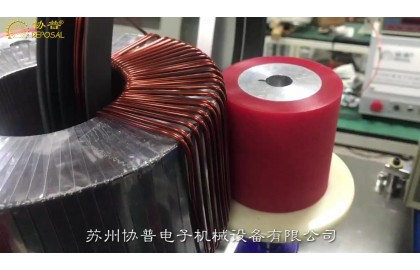

Ring wrap tape machine

Ring wrap tape machine

We will now demonstrate the operation of the loop coil strapping machine again, take the product, put it in, and then buckle this storage ring. Note that the insulating tape must pass between the two blades of the scissors After the fixed storage coil count is reached, the toroidal coil wrapping machine will rely on it to cut the insulating tape. Then, one end of the tape can be passed through any position of the bearing evenly distributed on the storage ring. After passing through, take the head of the insulating tape and hold it with the head, and then press and start with the right hand. The entire loop coil is covered with insulating tape It's done automatically.

Toroidal transformer winding machine

Toroidal transformer winding machine

The company has the advantages of R&D and production of electronic transformers and transformers in the whole factory equipment. Different from many assembly manufacturers in the industry, we have accumulated many years of experience in R&D and production in the winding machine industry and developed a new generation of toroidal coil series winding The equipment is widely used in the manufacturing industries of toroidal transformers, transformers, voltage regulators, inductance coils, etc., and has been well received by the industry; Suzhou REPOSL will continue to understand user needs and strengthen technical research and development and after-sales service levels, and provide customers with more professional and high-quality products and service.

Technical features of our toroidal transformer winding machine:

Using CNC digital intelligent program controller, stable work, simple operation, with a number of industry-first advanced and practical functions.

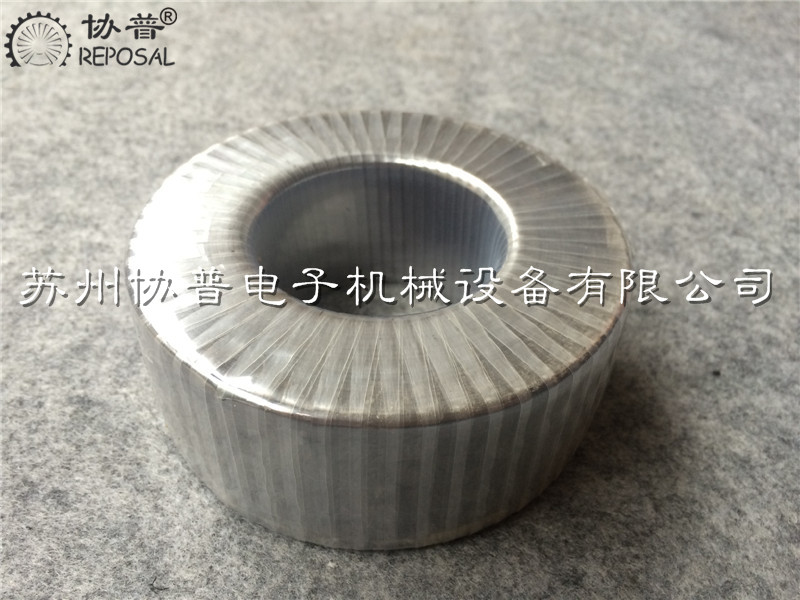

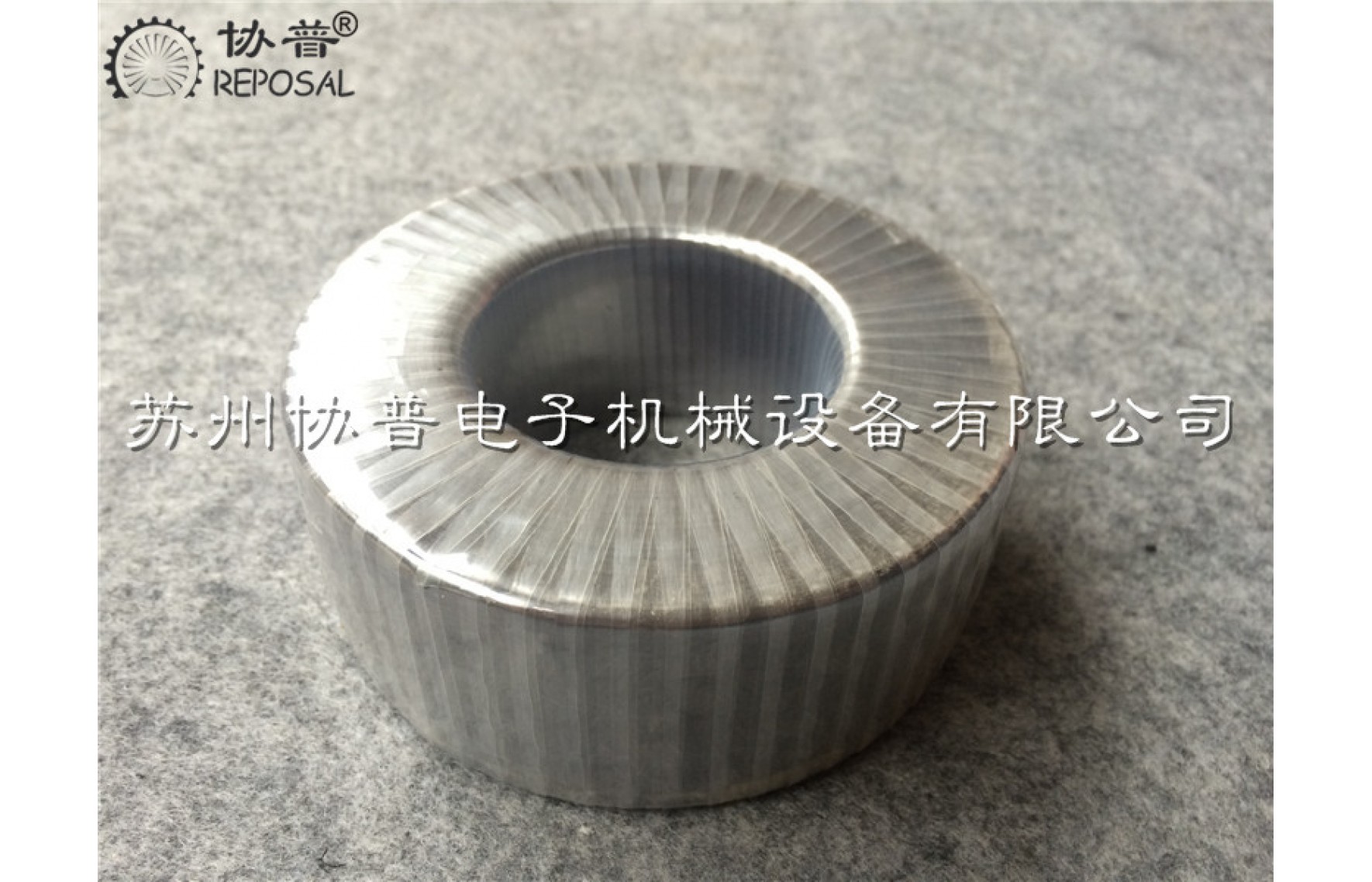

The core components such as the thread storage ring and the thread belt are made of high-quality steel through multiple processes, which are durable and not deformed.

It adopts advanced control circuit and has fault alarm function. The function switches are all controlled by two lines, which is easy to maintain and replace.

The operating speed is set separately in the storage and winding state, which can automatically realize the fast storage and low-speed winding operation. The automatic operation function can also be used in the taping machine mode. The operation is simple and the use efficiency is high.

When processing multi-winding products, multiple storage and multiple winding procedures can be preset, which is suitable for products with multiple windings but different wire diameters/numbers of turns, or products with insufficient wire storage in a single time, eliminating repeated installation Clamping and manual operation improve production efficiency.

Multiple sets of wire density can be preset, and the device can automatically change the preset wire density when winding. When processing multi-winding products, each winding with different turns can be evenly arranged at a preset angle.

Double frequency conversion proportional drive, automatic operation or pedal speed regulation can be selected.

The speed can be adjusted steplessly, and the appropriate winding speed can be set according to the process requirements of different products.

Features:

The gear winding machine has the characteristics of large winding torque, high opening size of the gear ring roof ring, a large amount of wire storage and a large range of suitable winding diameters. It is the most versatile

Winding model; suitable for products with thick winding diameters, neat wiring requirements and multiple parallel windings, such as small toroidal transformer secondary windings, high-power 驽

Technical features of our toroidal transformer winding machine:

Using CNC digital intelligent program controller, stable work, simple operation, with a number of industry-first advanced and practical functions.

The core components such as the thread storage ring and the thread belt are made of high-quality steel through multiple processes, which are durable and not deformed.

It adopts advanced control circuit and has fault alarm function. The function switches are all controlled by two lines, which is easy to maintain and replace.

The operating speed is set separately in the storage and winding state, which can automatically realize the fast storage and low-speed winding operation. The automatic operation function can also be used in the taping machine mode. The operation is simple and the use efficiency is high.

When processing multi-winding products, multiple storage and multiple winding procedures can be preset, which is suitable for products with multiple windings but different wire diameters/numbers of turns, or products with insufficient wire storage in a single time, eliminating repeated installation Clamping and manual operation improve production efficiency.

Multiple sets of wire density can be preset, and the device can automatically change the preset wire density when winding. When processing multi-winding products, each winding with different turns can be evenly arranged at a preset angle.

Double frequency conversion proportional drive, automatic operation or pedal speed regulation can be selected.

The speed can be adjusted steplessly, and the appropriate winding speed can be set according to the process requirements of different products.

Features:

The gear winding machine has the characteristics of large winding torque, high opening size of the gear ring roof ring, a large amount of wire storage and a large range of suitable winding diameters. It is the most versatile

Winding model; suitable for products with thick winding diameters, neat wiring requirements and multiple parallel windings, such as small toroidal transformer secondary windings, high-power 驽

Outer diameter: 193mm

Inner diameter: 95mm

Height: 90mm

Enameled wire diameter: 2.5mmX370

Video instructions for use of toroidal transformer winding machine

Suzhou REPOSAL Electronic Mechanical Equipment Co., Ltd. specializes in providing: toroidal transformer winding machine, current transformer winding machine, voltage transformer winding machine, ring voltage regulator winding machine, inductance coil winding machine, iron core chamfering machine , Parallel winding machine and other coil processing equipment and winding machine accessories.

The company has the advantages of R&D and production of the entire plant of electronic transformers and transformers. It is different from many assembly manufacturers in the industry. We have gathered many engineering and technical personnel in the winding machine industry. After many years of research and development and production experience, we have developed a new generation of series winding. Equipment, especially toroidal winding equipment, is widely used in manufacturing industries such as toroidal transformers, transformers, voltage regulators, inductive coils, etc., and has received many praises from the industry; Customers provide more professional and quality products and services.

Toroidal coil winding machine operation video-Machine operation

Below we introduce the structure of this toroidal coil winding machine. This part is the controller and this part is the clamping base. We control the product clamping by opening and closing the handle. This position is the storage ring. The enameled wire is stored on the storage ring first, and then wound around this product. This position is a manual winding handle. Turn this handle. The steel plate can be driven manually. The steel ring has an opening. This position is an opening. The opening is opened and closed by sliding the handle up and sliding to the left. . This position is called the crimping plate, and this position is called the baffle. After the line is removed, its degree of tightness is determined by the tension of the belt. The tension of the belt is adjusted by the tension adjustment knob. When adjusting the tension of the belt, first loosen this And then rotate the handle. When rotating the handle, there is an idler wheel. When the idler wheel goes in, the tension of the belt will increase, so that the winding of the enameled wire will become tighter.

Storage-and-recall-of-winding-machine-process-parameters

The company's CNC winding machine supports the storage of 1000 sets of winding process data. After you complete the winding process data of a coil, it will be automatically saved. When you debug the next product, you only need to start the setting from the next program number The parameters are enough. When you need to produce the original product, you can also call it very conveniently. The video below illustrates the storage and recall of the company's winding machine process data.

Let's introduce the process program of REPOSAL automatic winding machine.

Store and recall.

It can be stored in Xiepu's automatic winding machine controller.

1000 different process procedures.

How do we switch.

Press the starting step.

Press 1 and press enter.

Then press the end order.

Press 1 to enter and press to reset.

Then we set the order by part and press the input.

We will find that we continue to press enter.

Press the words after entering.

It will be set within the scope of Procedure 1.

Starting point means to start from where.

We can specify by this arrow.

We can also enter numbers directly.

For example, this is 36.5.

We can enter 37.

This is the starting point.

Then we can specify the width for him.

The width we are talking about is how big the line is.

Winding back and forth within a range.

Then we can set his enameled wire diameter.

For example, the diameter of the enameled wire is 0.4 mm.

Setting-of-technological-parameters-of-winding-machine

The company's CNC winding machine controller has been continuously improved, with complete functions and stable performance. It can accurately set the main parameters such as starting point, wire diameter, width, high speed, low speed, etc., and also include such as start slow speed, stop Auxiliary parameters such as slow speed, stop at both ends, these commonly used parameters are designed in the user parameter setting area. The following video explains the parameter setting process of our company's CNC winding machine in more detail:

Now we introduce the setting of process parameters of Xiepu winding machine.

The controller of Xiepu winding machine is divided into these major functions.

This part is called the digital parameter area.

It represents the current state of the machine.

For example, the red light here corresponds to the standby state.

It means that this machine is in standby state.

The following states are running, slowing, positioning, speeding.

This is a status area to monitor the current status of the machine.

This is a numeric parameter area.

The digital parameters need to be some numbers that we need to set.

at this place.

This is a switch parameter.

For example, when the cable direction starts.

Whether from left to right or right to left.

This is the cable direction.

There is also the winding direction.

For example, when we are standing on the right side of the machine.

See if the spool is rotating clockwise or counterclockwise.

Then choose the direction.

Then there are some special functions.

For example, parking at both ends, automatic stopping, automatic homing, etc.

These functions may need to be turned on.

This is a parameter of the nature of the switch.

So this is a switch parameter area.

This part is an editing area.

It is our numbers and clear, copy, confirm, etc.

This is in the editing area.

Then this is an interrupt area outside the interrupt area.

For example, we need to specify the automatic mode.

Or retreat, jump, stop, start.