REPOSAL® machine for radiofrequency ablation catheter

A radiofrequency ablation catheter is a medical device used to treat arrhythmias through which radiofrequency energy is delivered to a specific part of the heart to dissolve the cardiac tissue causing the arrhythmia. Its market size is growing and is expected to maintain a steady CAGR in the coming years. The market size of China's radiofrequency ablation catheter has reached a certain amount since 2020, and is expected to reach a higher market size by 2027.

There are several players competing for market share in the radiofrequency ablation catheter market, including well-known medical device companies such as Medtronic, Biotronik, and MicroPort Scientific. These companies maintain their market position through continuous innovation and product optimization in the design and manufacturing of RF ablation catheters.

By improving the transmission and distribution of radiofrequency energy, the ablation efficiency can be improved and the damage to surrounding normal tissues can be reduced. Three-dimensional navigation system and real-time imaging technology are used to make the ablation process more accurate and controllable. Research and development of catheters with multiple electrodes capable of simultaneous ablation at multiple points, or by integrating different sensors and monitoring devices, such as pressure sensors and temperature sensors, to optimize the ablation process. New materials and improved catheter design are used to improve catheter flexibility, durability and biocompatibility. For example, special cooling techniques are used to reduce heat damage, or catheters made of biodegradable materials are developed to reduce foreign body reactions in patients. Reducing the risk of complications during surgery through technological innovations, such as the development of cooling systems and pressure monitoring functions, as well as improving the operability and comfort of catheters, makes the procedure smoother and safer.

In addition to radiofrequency ablation, other types of ablation techniques, such as microwave ablation, cryoablation and pulsed electric field ablation, are also being explored to provide more treatment options and better therapeutic outcomes. Optimize the manufacturing process of ablation catheters to improve the quality and performance of catheter coils by improving manufacturing processes, such as RF catheter winders, while reducing production costs and increasing production efficiency.

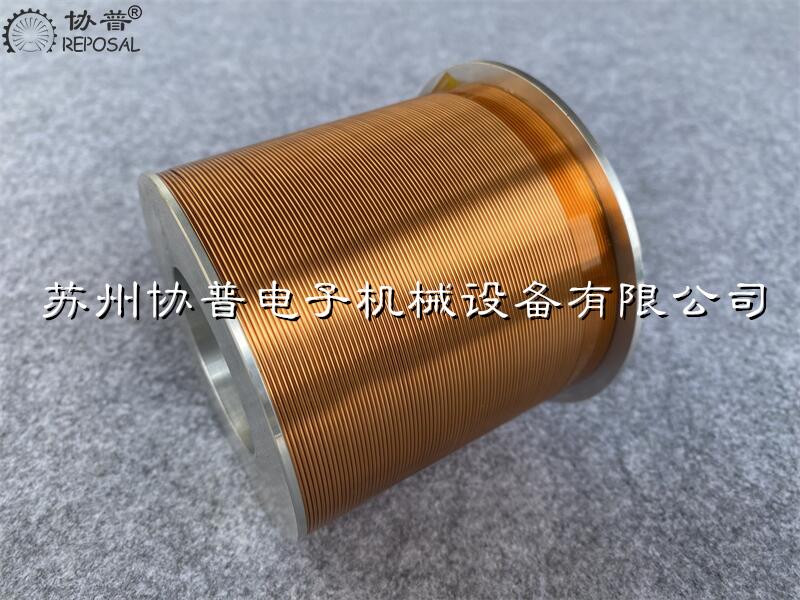

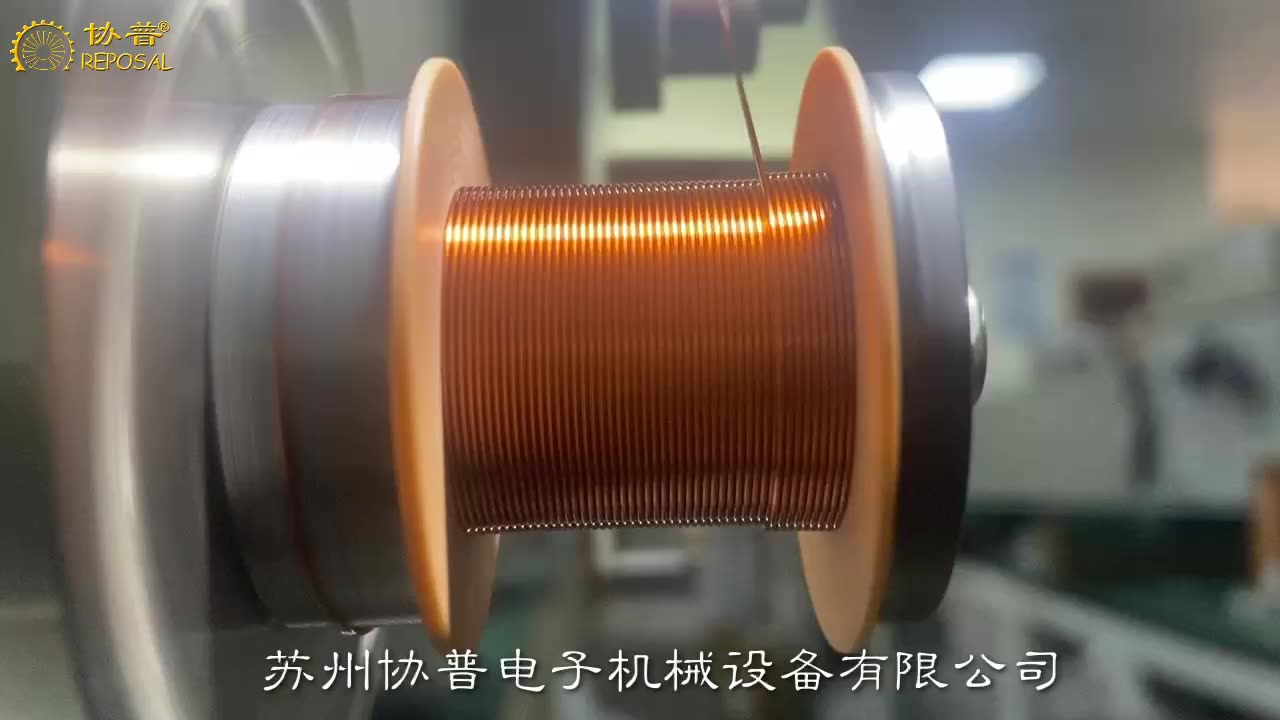

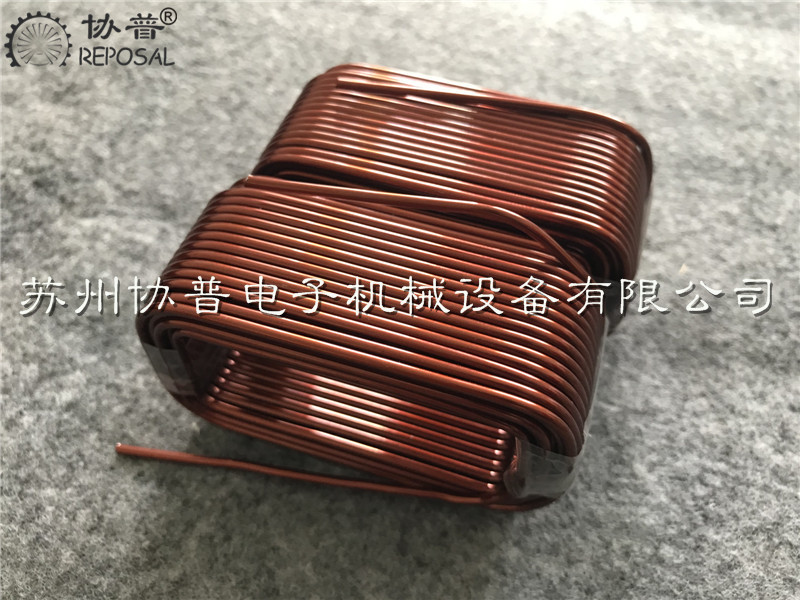

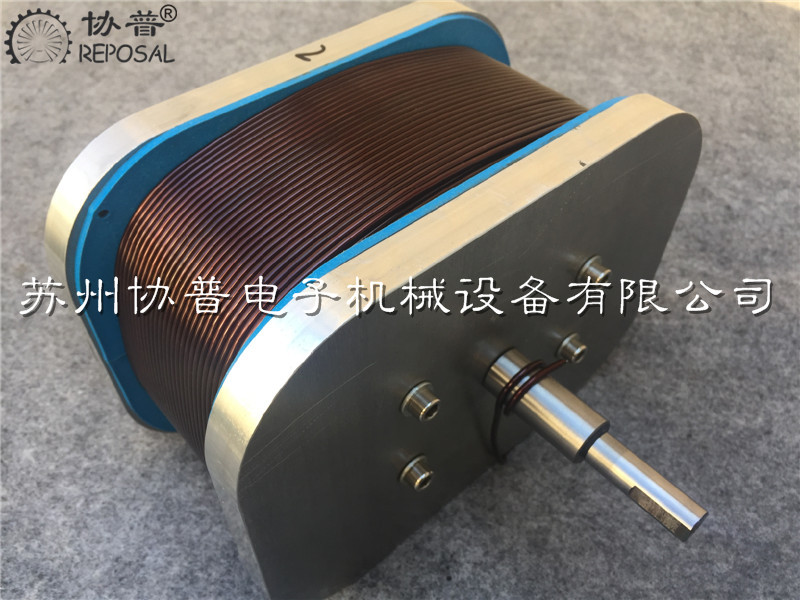

In terms of the above innovation and optimization, the coil winding of ablation catheter plays a crucial role in the production of radiofrequency ablation catheter, which directly affects the performance and therapeutic effect of the catheter. As a professional precision winding solution provider, REPSOAL® has successfully developed a radiofrequency ablation catheter winding machine with the support of several medical device companies after several iterations.

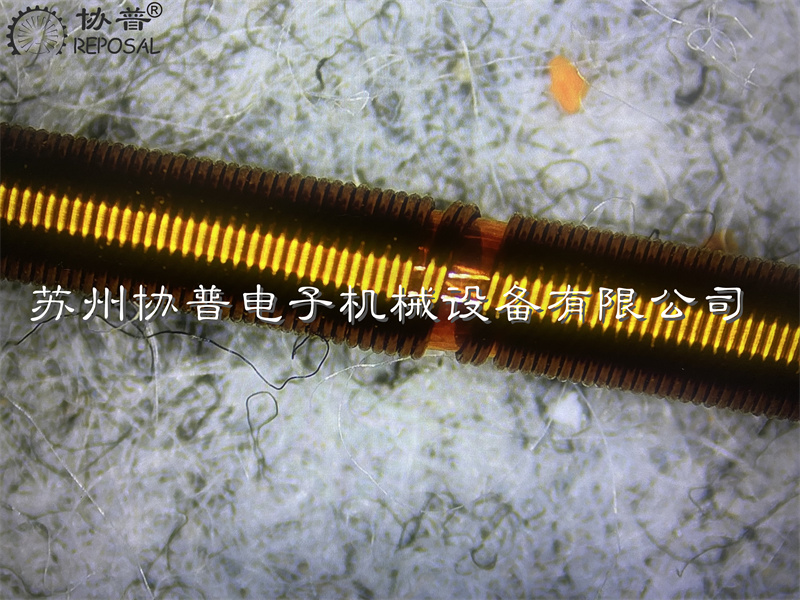

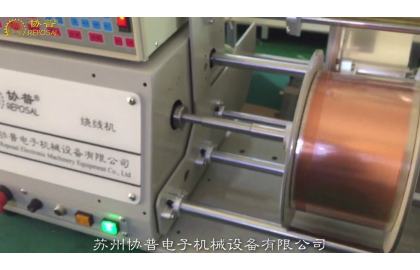

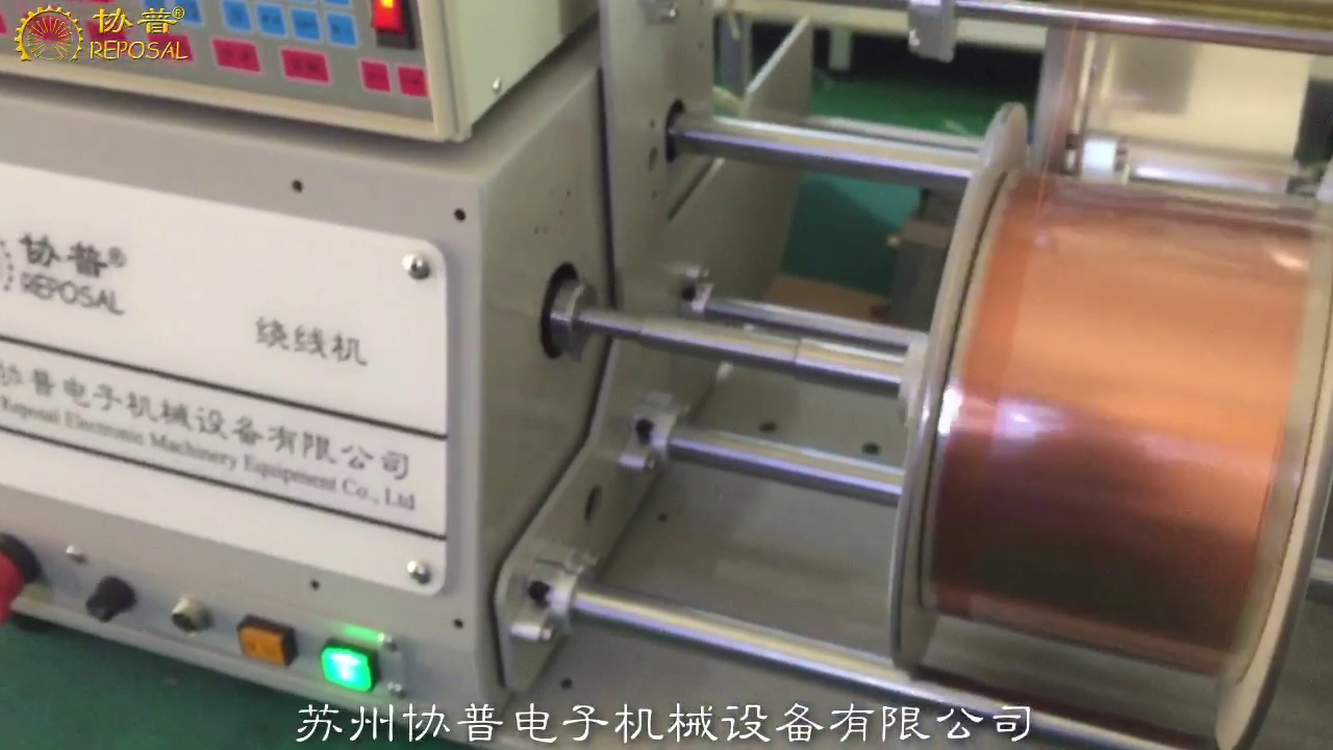

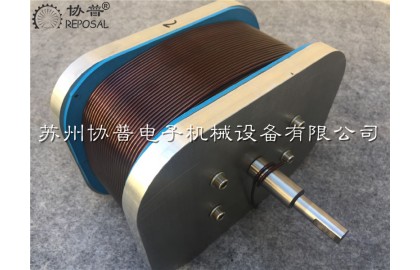

Radiofrequency ablation catheter winding machine is a winding equipment specially designed for the production of radiofrequency ablation catheter. It combines the production process of radiofrequency ablation catheter, develops the corresponding mechanism and control system, and is easy to operate. The user interface and operation process of the radiofrequency ablation catheter winding machine are very convenient for operators to quickly get started and maintain. In the process of drawing, folding, double-strand winding, latching and curing, the optimized process route and precise process management ensure that the produced RF ablation catheter coil has a high degree of consistency and stability.

Through deep cooperation with medical device companies, our radiofrequency ablation catheter winding machine has gone through many iterations, which has greatly improved the product competitiveness of our partners. According to the feedback of our partners, the winding process of the radiofrequency ablation catheter winding machine has improved the efficiency of radiofrequency energy transfer to the target tissue. The precise winding process ensures the efficient transfer of energy, thereby improving the efficiency and consistency of ablation. The uniformity of the precision wound coil affects the temperature distribution of the ablation area, avoiding local overheating or heat deficiency, which is essential to ensure the ablation effect and reduce complications. The stability of the winding process ensures the reliability of the operation. The high-quality winding process withstands stretching and bending during surgical operations, reducing the risk of breakage or functional failure. High-quality winding processes have a longer service life and are able to maintain stable performance through multiple operations, thereby reducing medical costs and improving resource efficiency. The quality of the winding process also affects the precise control of the ablation process. The high-precision winding process helps physicians to more precisely control the size and shape of the ablation area to achieve optimal treatment results.

Moreover, the RFA catheter winder is designed with operational safety in mind, reducing potential risks during operation and protecting operators and products from damage. It can adapt to different types of radiofrequency ablation catheter production requirements, and has good flexibility and scalability. The structure and design of special winding machines are often more simplified and easier to maintain and maintain, thus reducing long-term operating costs.

The advantages of radiofrequency ablation catheter winding machine are mainly reflected in professional design, high efficiency production, precise control, quality stability, easy operation, material saving, safety, strong adaptability, low maintenance cost and technological innovation. These advantages make the radiofrequency ablation catheter winding machine an indispensable key equipment in the production process of radiofrequency ablation catheter.