Introduction of winding method of electric heating tube

Pipeline heating is a relatively common heating load in the industry. It is commonly used in plastics, rubber, petroleum pipelines, heating equipment, water heaters, molds and other equipment. The traditional pipeline heating uses resistance bands or electric heating tubes for heating, resistance heating Although the cost is relatively low, the thermal efficiency is low, only below 60%, and it is relatively easy to break. Frequent repairs and replacements affect the production capacity of the overall equipment and bring great inconvenience to users. With the development of variable frequency power electronics, electromagnetic induction eddy current heating can be used to solve this problem. Since the principle of electromagnetic heating is non-contact heating, and the thermal efficiency is as high as 95%, it is favored by many users. However, the whole equipment of electromagnetic heating involves a wide range of knowledge, not only understanding electricians, but also understanding electronics. The method of making coils, heating and winding, has brought a lot of difficulties to many users. Here, I will introduce you to pipeline electromagnetics. The winding method of the coil makes the winding technology of the advanced electromagnetic tube no longer difficult, and everyone understands the application technology of electromagnetic induction heating, and the technical support of the REPOSAL® winding machine.

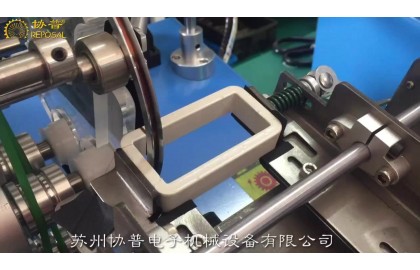

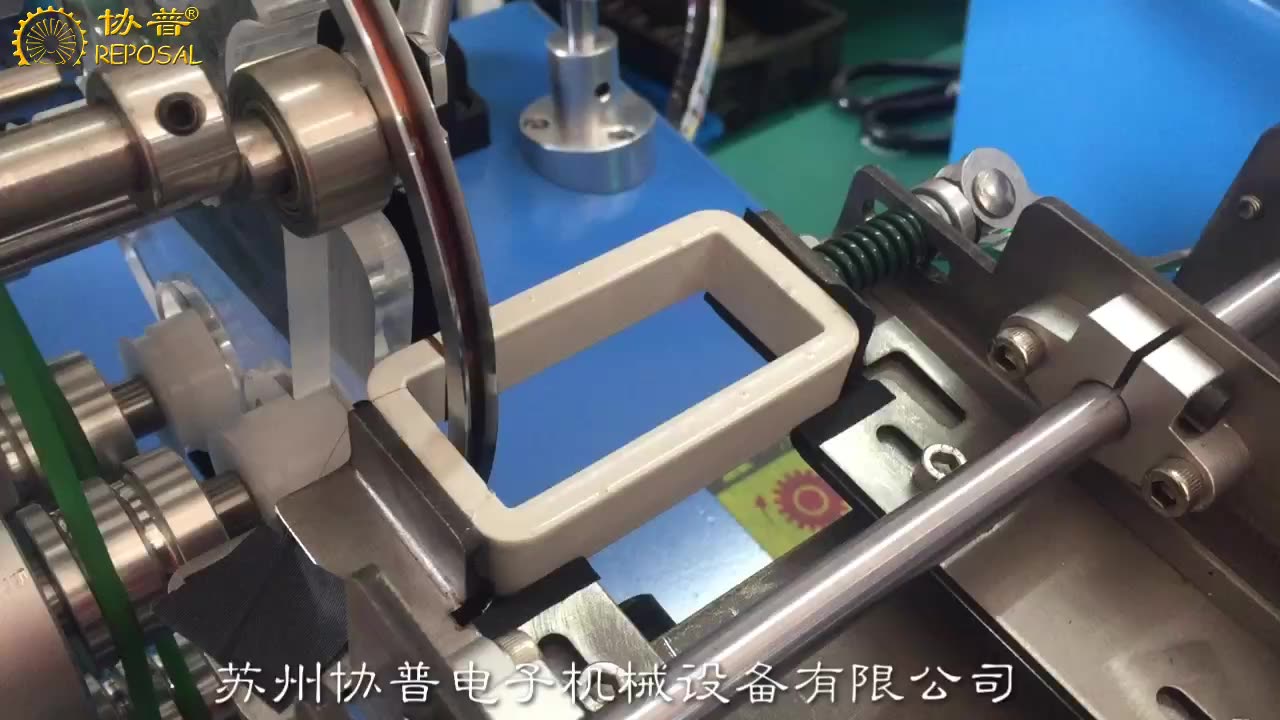

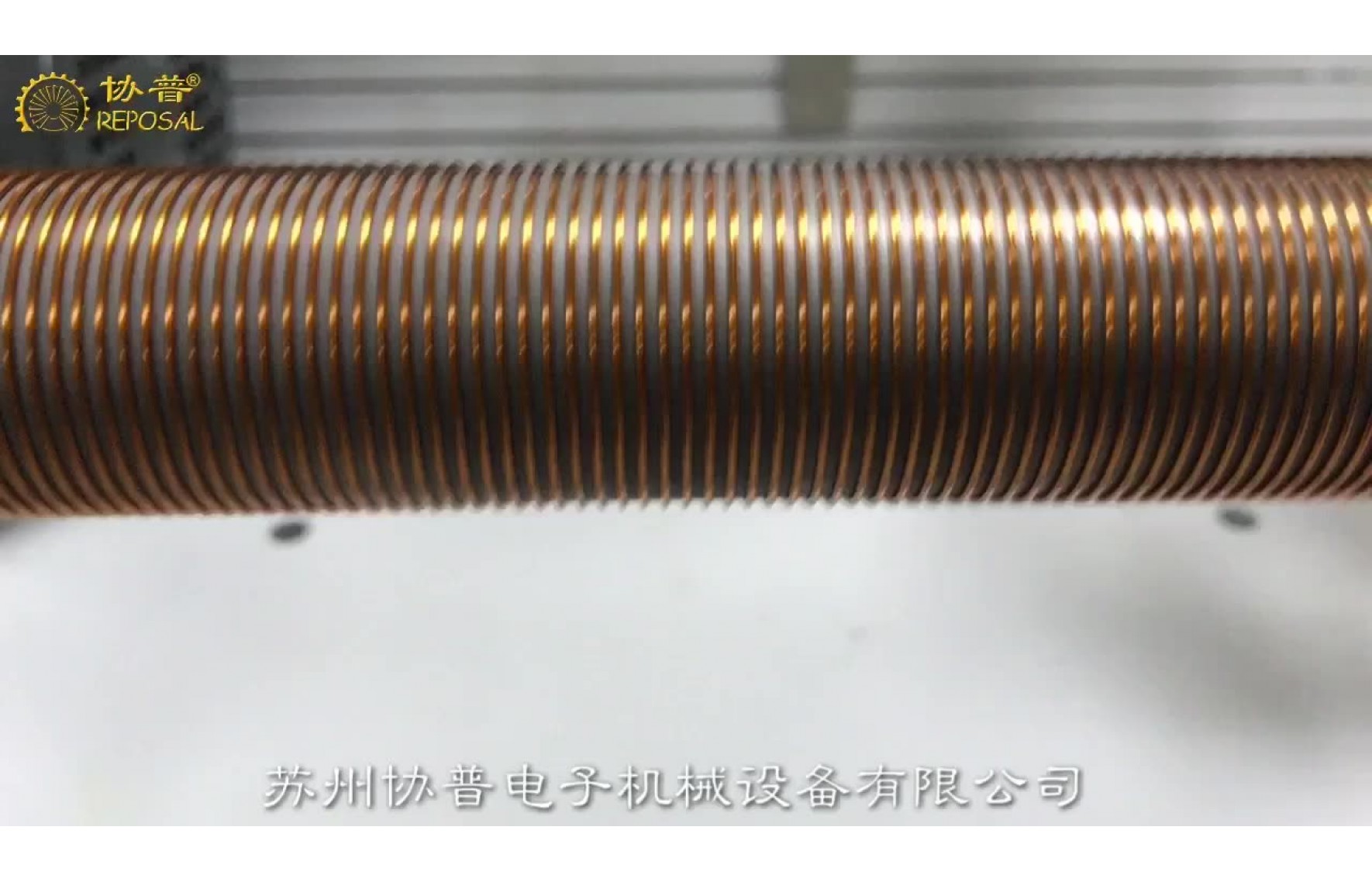

This type of winding machine of Xiepu has a stroke of 1.5 meters, adopts pneumatic quick assembly and quick disassembly, convenient operation, mature and stable structure, easy maintenance, easy operation of the system, complete functions, and strong expandability.

At present, according to the customer's request, the heating coil with a stroke of up to 1.5 meters is wound on this machine. Because the equipment is structured in place, the winding has a satisfactory effect. The customer currently plans to add a mica tape winding function on this basis.

Winding method of electromagnetic induction heating coil

1. Material preparation:

1.1 One set of special winding machine for Xiepu's 1.5m long stroke

1. 2A hollow Wuxi steel pipe with a diameter of 32mm is 1.5 pieces long.

1. 330mm glass wool blanket insulation material, 2 meters long and 1 meter wide

1.4 16mm2 national standard mica glass fiber high temperature wire, 50 meters

1.5 Glass fiber cloth, width 100mm, 1 roll

1.6 digital electric bridge

1.7Several 100A wire ears

2. Detailed explanation of modification method:

2.1 Choose a layer of 30mm glass wool blanket insulation material outside the heated pipe, and wrap it around, no more layers! It's exactly a circle, about 1.5 meters in length.

2.2 Wrap the insulation material with glass fiber cloth, lightly wrap it, and don't press it too tightly!

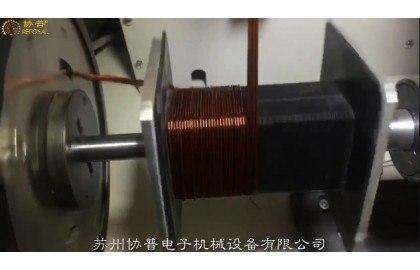

2.3 Wind up the prepared 50m 16mm2 national standard mica glass fiber high temperature wire, and ensure that the lead wires on both sides are about 1.5~2 meters. The space should not be too dense, because the coil is also heated when it is working, so ensure a certain interval to dissipate heat.

2.4 Use the digital bridge to measure the inductance, and adjust it to L to measure the inductance of the 2mH file. The inductance of about 200-250uH can complete the coil production.

2.5 Finally, tie the two ends of the coil with a cable tie to prevent the coil from loosening and falling off. No protective measures are needed on the outside of the coil, because the outside of the coil is originally wrapped by mica, which is an insulating material and will not pose an electric shock hazard to the human body. Special attention should be paid to the fact that there should be no metal materials within 200mm outside the cable, otherwise it will heat up! If you really need to shield the magnetic field, you can wrap it with an aluminum plate about 100mm from the back of the line, but it can’t be completely wrapped. Leave more than 10mm and fix it with an epoxy plate. It must not form a loop, otherwise it will be caused during working hours. Sparks, in severe cases, may cause safety accidents.

2. 6 Finally, connect the A B C terminal on the electromagnetic heating controller to a three-phase 380V power supply, connect the L1 and L2 terminals to both ends of the coil, and short-circuit the R/S terminal or press and hold the red button to start. When working, the current value is displayed, and it is generally qualified between 43-45A. Press the green button again to see the working frequency between 10-18kHz is qualified. If the frequency is too low, reduce the number of turns of the coil, otherwise increase the number of turns of the coil. Make the controller work within the range of ideal working parameters. After completion, after leaving enough leads, the excess wires can be cut off. The Jiangxin electromagnetic heater should be placed in a well-ventilated place. If it is placed in a cabinet, an exhaust system must be made and good air convection must be ensured.