Research and design of enamelled wire tensioning force control system for REPOSAL ® winding machine

With the development of our society and the progress of science and technology, the demand for high frequency and high voltage special power supplies in all walks of life is increasing day by day. The main core process in the production and manufacturing of high frequency and high voltage power supplies is the winding of interlayer insulated high voltage pack coil, and the technical level of interlayer insulated high voltage pack coil winding depends on the technical level of coil winding machine. But at present, the domestic high pressure coil winding machine has a low degree of automation, poor processing quality and production efficiency, and can not realize the automatic arrangement of enameled wire and insulated tape. In addition, the tension control technology of the wire is backward, the acceleration of the transmission speed, the change of the radius and the radial runout and axial movement of the winding spindle during the winding process will lead to the sudden change of the tension force of the wire, resulting in the turn to turn row of the interlayer insulated high voltage pack coil deviating from the ideal value, and the low quality of the wound interlayer insulated high voltage pack coil. In this context, the company began to develop high pressure coil winding machine and enameled-wire tension control system, the main research content is as follows:

Firstly, the process of layer wound high pressure packet winding machine is analyzed, the mechanical structure of layer wound high pressure packet winding machine is determined, and the related concepts of tension control of enameled wire are introduced. Secondly, an automatic wiring control system is designed, and the influence of the lagging Angle on the quality of the interlayer insulated high pressure pack coil is studied, and the trajectory of the wiring is analyzed. In view of the high requirement of motor control algorithm in the process of enameled wire winding, the multi-motor cooperative control is analyzed, and the parameters are selected by MATLAB simulation and optimization according to the actual requirements of the project, and the multi-motor cooperative control scheme of the multi-motor of the multi-motor coiler is designed. Then, taking the insulation layer rewinding system of the high pressure packet winding machine as the research object, the mechanical model of the system is analyzed dynamically.

The fuzzy control idea is introduced and the control scheme of fuzzy enamelled wire tension is designed according to the concept of enamelled wire tension control. Control parameters were selected, different enamented wire tensioning forces were selected as control targets according to the actual requirements of the project, and the feasibility and advantages of the scheme were verified by comparison with the traditional PID control method. Finally, the hardware system design and hardware selection of the winding machine are introduced, and the software environment of the winding machine is introduced, and the man-machine interface matching the system is designed to facilitate the observation and control of the operator.

Through the analysis of the simulation curve of the fuzzy enamelled wire tension system, it is proved that the fuzzy PID-based enamelled wire tension control system can quickly adjust the tension fluctuation of the enamelled wire in the process of insulating tape winding. During winding, the torque of the unwinding rod, the torque of the electromagnetic brake rod and the rotational speed of the main speed can buffer the change of the tension of the insulated enameled wire and compensate the tension of the interlayer insulated HV coil. By comparing and analyzing the fuzzy PID control with the traditional PID control, it is proved that the fuzzy PID control scheme has faster setting time and lower steady-state error than the conventional PID control scheme in the steady state and acceleration stage, and the system can keep the tension of the enameled-wire constant under different reference wire tension and transmission conditions.

In recent years, with the rapid development of science, technology and economy in our country, the demand for high frequency and high voltage special power supply is increasing. As the top priority of high frequency and high voltage special power supply system, the internal interlayer insulated high voltage pack coil is an important part. The winding quality of enameled wire and insulated tape in interlayer insulated high voltage pack coil directly determines the reliability of high frequency and high voltage power supply in special high frequency and high voltage power supply system, and the winding quality of interlayer insulated high voltage pack coil largely depends on the performance of the layer wound high voltage pack coil winding machine. The requirement for the performance of the high-voltage coil winding machine is getting higher and higher. A high voltage coil winding machine with excellent performance should meet the requirements of safety, intelligence, high efficiency and other control requirements, need to have high stability hardware equipment and easy to operate software, and the performance of modules such as enameled wire tension control should also have enough design redundancy. At present, China's layer wound high pressure pack coil winding machine industry backward development, intelligence and stability is poor, high-end layer wound high pressure pack coil winding machine equipment mainly relies on imports, the price of imports is very expensive. In this case, it is of great practical significance for our company to study the winding machine of layer wound high pressure pack.

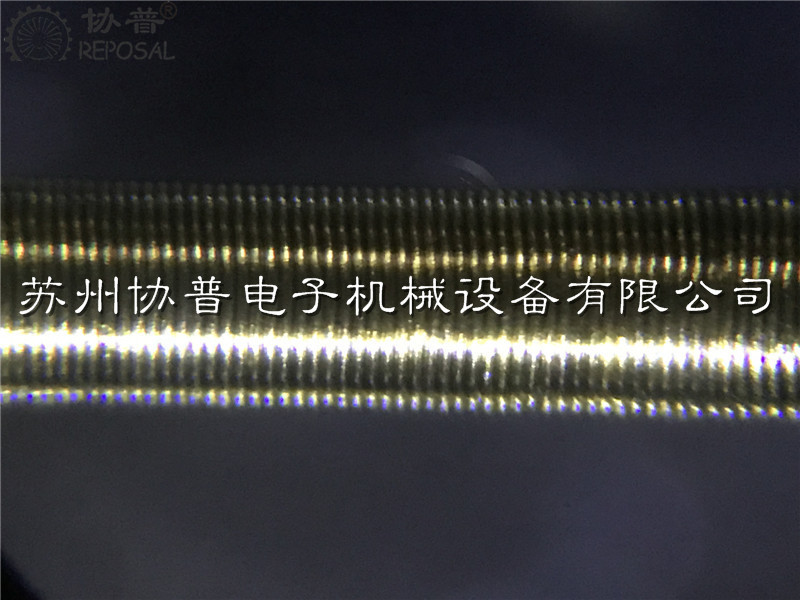

Most of the coil material of the high pressure coil winding machine is metal enameled wire and insulating paper, which has a certain elastic coefficient. The acceleration of the coil conveying speed and the change of the radius of the coil will change the tension of the enameled wire. The constant enameled wire tension control is an important index to ensure the stability of the system. For example, in the process of winding up and unwinding of the layer wound high voltage packet coil, the Angle speed of the winding rod remains constant, and the change of the coil radius will cause the fluctuation of the tension of the wire. Too much tension will lead to the thinning of the wire or even fracture, and too little tension of the wire will lead to uneven material arrangement or wrinkles, affecting the quality of the insulation between layers of the high voltage packet coil of the high frequency and high voltage power supply. Therefore, the performance of tension control of enameled wire directly affects the quality of high frequency and high voltage power supply in the production process of layer wound high voltage coil winding machine. Compared with foreign companies, the tensioning force of the enamelled wire of the existing domestic lamellar coil winding machine is generated by mechanical friction, and the tensioning force of the enamelled wire is unstable, which will cause the defects of sparse arrangement of the enamelled wire and the insulation tape, and the outer diameter of the interlamellar insulated coil. In addition, the overall development level of China's domestic high-voltage coil winding machine is low, compared with Europe and the United States and other developed countries, there is a certain gap in processing quality and production efficiency. It is reflected in the following aspects:

1. Manual operation is required when wiring, adding inter-layer insulation layer and end insulation layer.

2. In the production and processing process of the layer-wound high pressure packet coil winding machine, the motor starts quickly when the winding starts, and the motor needs to reverse and wind the next layer when the winding reaches the edge, so as to reciprocate, the tension of the enamel wire fluctuates greatly, leading to the irregularity of the interlayer insulated high pressure packet coil, and the quality of the interlayer insulated high pressure packet coil is poor.

Three. The mechanical structure of the domestic winding machine is simple, and it can not wind the complex interlayer insulated high pressure pack coil.

In summary, it can be seen that the performance of the foreign layer wound high pressure packet coil winding machine is good, but the price is expensive, and the domestic layer wound high pressure packet coil winding machine is poorly developed and lacks core technology compared with foreign countries. In this situation, it is necessary to apply advanced technology in the independent research and development of domestic layer wound high-voltage coil winder, and improve the control performance of the manufactured high-frequency high-voltage power winder in order to better apply in industrial production. Therefore, the company combined with the advanced technology at home and abroad, designed the enamelled wire tension control system, the enamelled wire tension control and wire layout control technology, improve the core competitiveness of the domestic lamellar high pressure coil winding machine.

The layer wound high voltage pack winding machine is a special equipment for winding the layer insulation high voltage pack winding of high frequency and high voltage power supply, and has been widely developed and applied in the world. The foreign high-voltage coil winding machine started early, after years of development and research, has formed a complete system of high-voltage coil winding machine. The safety and production efficiency of the winding machine can be greatly improved by satisfying the quality of the interlayer insulated high pressure pack coil. Especially in Europe and the United States and other countries developed the layer wound high pressure coil winding machine, mechanical structure integrity, high degree of automation, good winding quality, good safety performance, in the global scope has a high market share.

The automatic layer-wound high pressure packet coil winding machine developed by developed countries in Europe and the United States can realize synchronous winding of enameled wire and insulation tape, with high winding precision, stable control of enameled wire tension and high production efficiency. After meeting the processing requirements of high speed, high precision, enameled wire and insulating paper tape winding at the same time, the wiring system has been designed. The geometry of the winding can be selected according to the structure of the interlayer insulated high voltage pack coil, and the AC servo motor is used as the driving core, and the excellent acceleration and positioning performance of the servo motor is used to achieve the purpose of accurate control of the feed wire, with high intelligence and stable working performance.

In terms of the control of the tensioning force of enameled wire, since the 1990s, foreign professional industry practitioners have studied the factors affecting the tensioning force of wire enameled wire, and studied the relationship between the tensioning force of wire enameled wire and the retracting reel. Since entering the 21st century, more practitioners and experts in the industry have begun to study the tension control of enameled wire. It is also applied to the high-voltage coil winding machine of the layer wound, and the track tracking control of the equipment is realized under large interference. By adding a flattening machine including an accumulator and a tensioning device to replace the traditional energy storage device, the winding speed can be changed under a certain tension fluctuation of the enamelling wire without affecting the winding quality.

In fact, China began to develop in the 1970s of the last century, through the imitation of foreign layer wound high pressure packet coil winding machine and the exploration and research of many industry practitioners, so that China's layer wound high pressure packet coil winding machine has obtained a rapid development, but also achieved certain results. However, due to the monopoly of the core technology in foreign countries, there is a certain gap between China and foreign countries, which is reflected in the manufacturing process and control scheme.

At present, the domestic high-voltage coil winding machine industry mainly lags behind foreign countries in that the insulation tape part needs to be manually wound, which makes the quality of winding products greatly dependent on the operator's proficiency, and the production efficiency is low. On the other hand, there is no good control scheme for the tension disturbance of enamel wire generated during the winding of insulated tape in China, which greatly affects the quality of the winding of interlayer insulated high voltage pack coil. Therefore, it is of great significance to develop a control system which can automatically arrange enameled wire and insulated tape and keep the tension of enameled wire constant during the process of winding insulated tape.

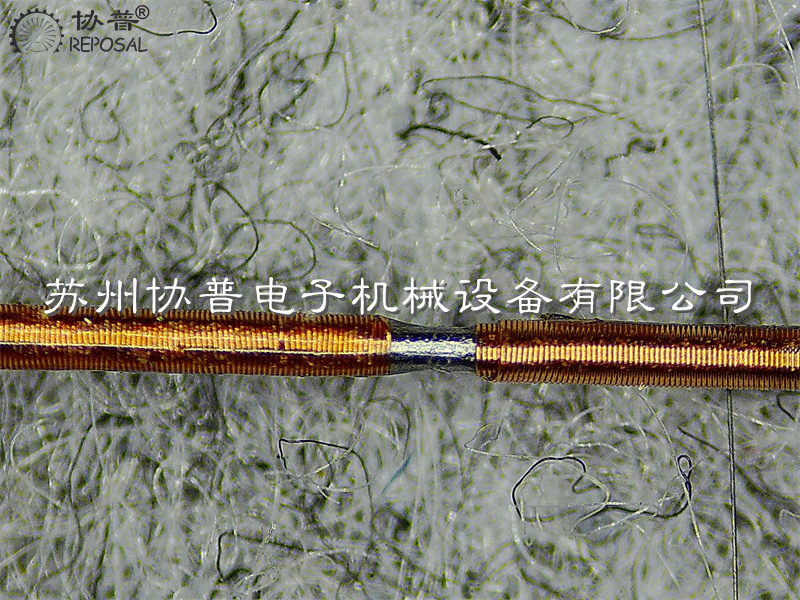

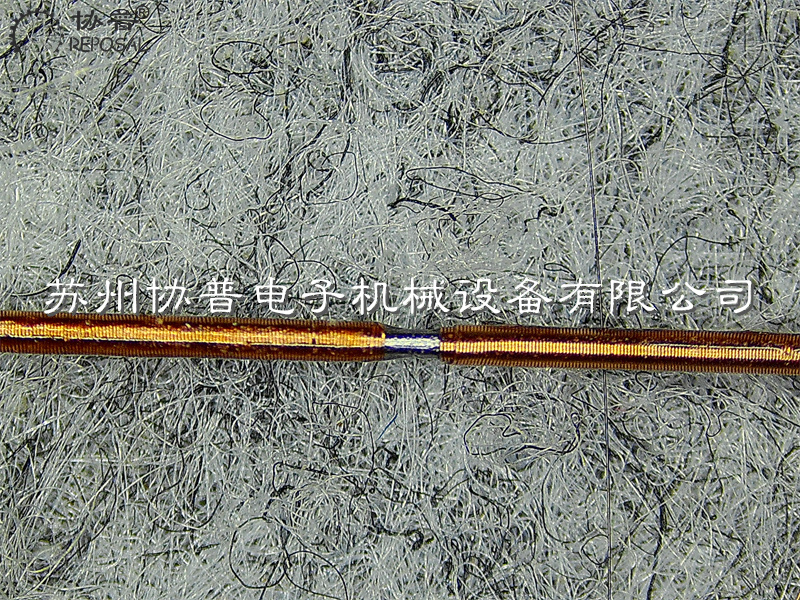

The tensioning force control of enameled wire is the key technology to control the equipment of the high pressure coil winding machine. The tensioning force control of enameled wire is not suitable to seriously affect the winding quality of the high pressure coil winding machine. When the tensioning force of the enameled wire is too small, it will lead to the winding defects of the enameled wire or insulation tape, such as relaxation, accumulation and folding. The tension of enameled wire is too large, which will cause the enameled wire or insulation tape to deform, stretch too much, and even break. The control of the tension force of enameled-wire directly affects the density between layers of the winding of high frequency and high voltage power supply.

At present, there are three main schemes for the tension control of enameled wire: manual tension control, semi-automatic tension control and automatic tension control. Manual control is to adjust the excitation current of the clutch and brake in different stages (generally by stepping on the pedal) in the winding process to meet the tension control of the enameled wire at different stages; The semi-automatic enameled wire tension control is to detect the reel speed through the proximity switch installed on the reel, calculate the current roll diameter by accumulative calculation, and adjust the tension of the enameled wire according to the change of the electric signal caused by the change of roll diameter. Automatic enamelled wire tension control is the tension detector to directly measure the tension of wire enamelled wire, and then convert the tension data of wire enamelled wire into an electrical signal to amplify the feedback to the controller. By comparing the signal with the tension value of wire enamelled wire set by the controller, the difference is calculated, and finally the actuator is controlled to adjust the tension of wire enamelled wire.

In the 1980s, most of the domestic control of the tension force of the enameled-wire winding machine was manually controlled, and with the increase of the demand for high-frequency high-voltage power supplies and the improvement of product quality requirements, this method was gradually replaced. Since the beginning of this century, many domestic industry practitioners have carried out in-depth research on the winding automatic enameled wire tension control system and developed different technical routes.

PLC is used to receive the feedback signal of the tension force of the enameled wire and the analog signal of the sensor, and the winding speed of the fine enameled wire is further controlled, and the control is accurate and stable during the winding process.

In view of the technical problems existing in the winding process of non-continuous coil, PID algorithm is used to realize the winding of non-continuous coil.

To solve the problem of line deflection and vibration in triaxial fiber winding machine, a constant enameled wire tension control system was developed, and an intelligent algorithm was added to adjust and optimize the winding parameters, which improved the processing quality of the triaxial fiber winding machine.

This paper studies the tension adjustment system of enameled wire in winding machine. In order to meet the demand of tension fluctuation of wire enameled wire in winding process, the pendulum rod type tension adjustment mechanism is adopted, and a precision Angle encoder is installed at the end of the pendulum rod to feedback the position of the pendulum rod in real time. In this way, the tension force of wire enameled wire is adjusted, and the work of winding bobbin is performed. The deformable PID control algorithm is used to adjust and optimize the parameters. The experiment proves that the winding effect of the winding machine is good.

However, due to the complexity of the mechanical structure of the high frequency and high voltage power supply winding equipment and many influencing factors, the tension control system of the coated wire has strong nonlinearity and coupling under different conditions, which is still the difficulty of the equipment control of the high voltage coil winding machine. The control of constant enamelled wire tension is an important index to ensure the quality of coil winding for the layer wound high pressure coil winding machine. Therefore, the research and development of the constant enameled-wire tension control system suitable for industrial production is of practical significance to the industry of layer wound high-voltage coil winding machine.

Based on the analysis of the research status of the domestic outer coil winding machine, aiming at the backward control technology and low degree of automation of the domestic high frequency and high voltage power supply winding machine enameled wire tension control system, the layer wound high voltage coil winding machine enameled wire tension control system is designed. The system can automatically wire the enameled wire and the insulation tape, and carry out accurate tension control of the insulation tape. The main research contents of the company include the following aspects:

This paper analyzes the production and processing process of the layer-wound high pressure packet coil winding machine, and designs the wiring system based on the mechanical structure of the layer-wound high pressure packet coil. The influence of the wiring lag Angle on the quality of the interlayer insulated high pressure packet coil is studied. In view of the high requirement of motor control algorithm in the process of wiring, the multi-motor cooperative control structure was analyzed, parameters were selected according to the actual requirements of the project for MATLAB simulation, the best algorithm was selected, and the multi-motor cooperative control scheme of the winding machine was designed.

Second, the design of the tension control system of enamelled wire in the layer wound high pressure pack winding machine. The mechanical model of the system is modeled, and the fuzzy PID control method is designed to control the tensioning force of the enameled wire by studying its mathematical logic, control principle and characteristics of various winding modes. According to the actual requirements of the project, different enamented wire tensioning forces were selected as the control targets to carry out MATLAB simulation experiments, and compared with the traditional PID control method, to verify the feasibility and advantages of the system.

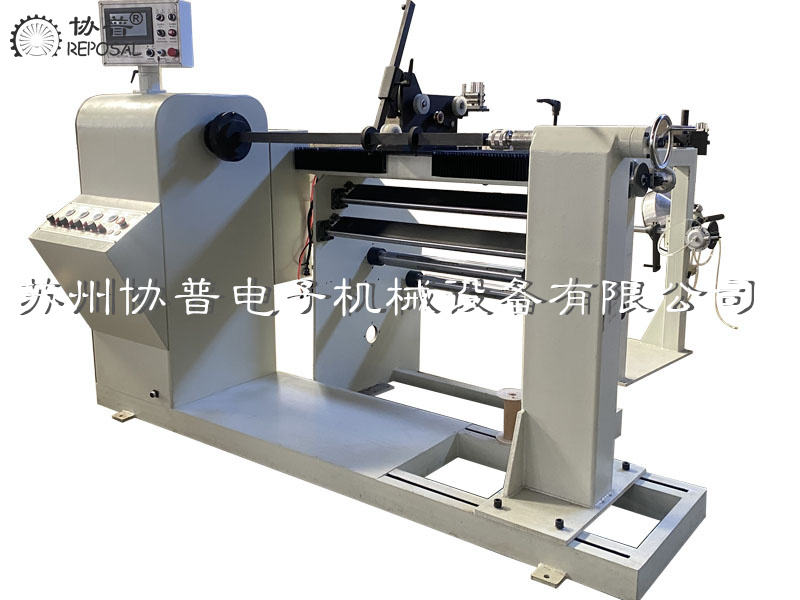

Third, the software and hardware design of the high pressure pack winding machine. Design the hardware system of the high pressure pack winding machine, select the hardware and make the statistics of the signal point table. The software flow chart is designed for the control system of wiring control and enamelled wire tension. Finally, the man-machine interface of the winding machine is designed to facilitate the operator to observe and control.

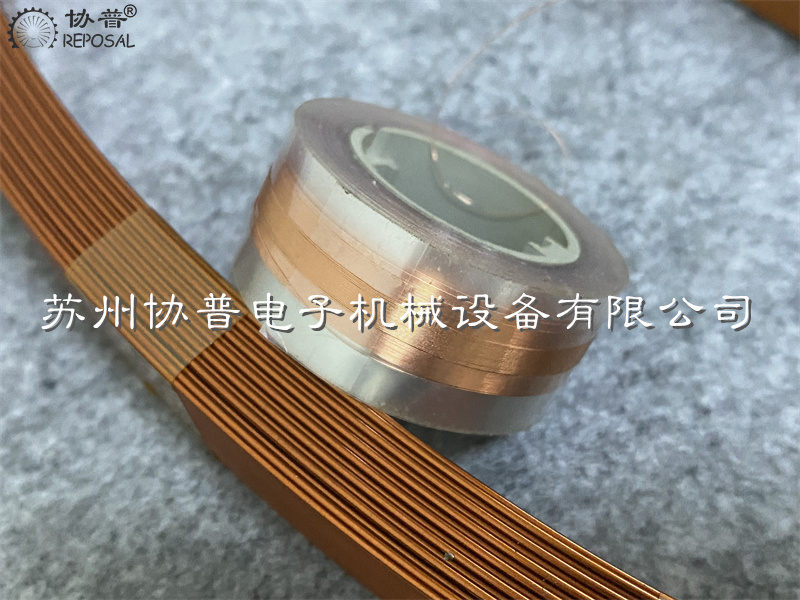

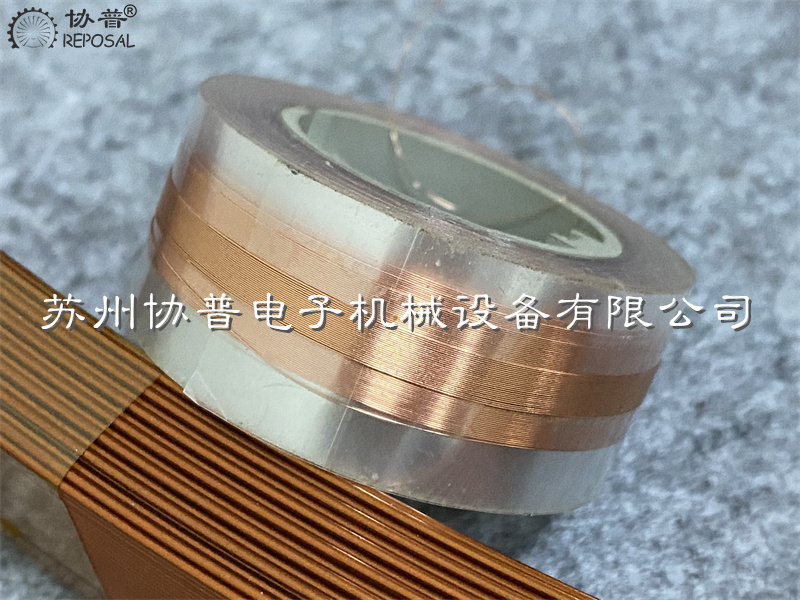

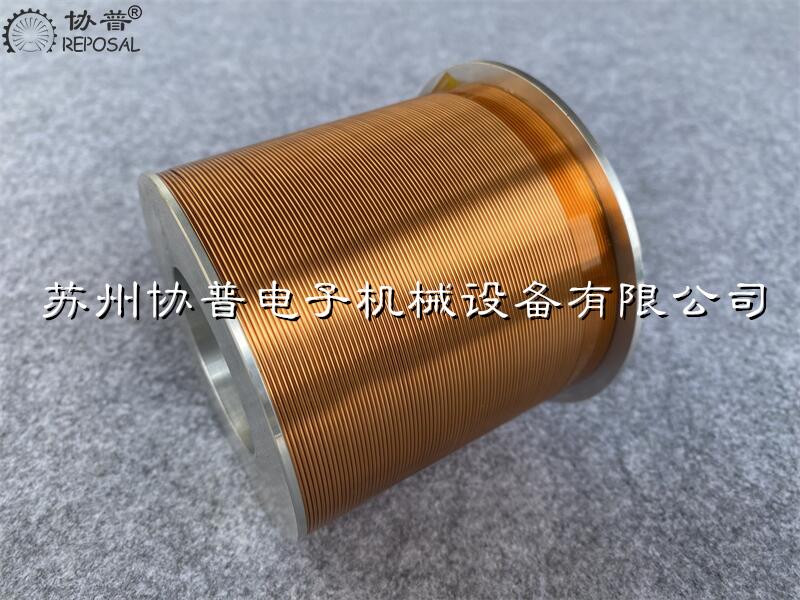

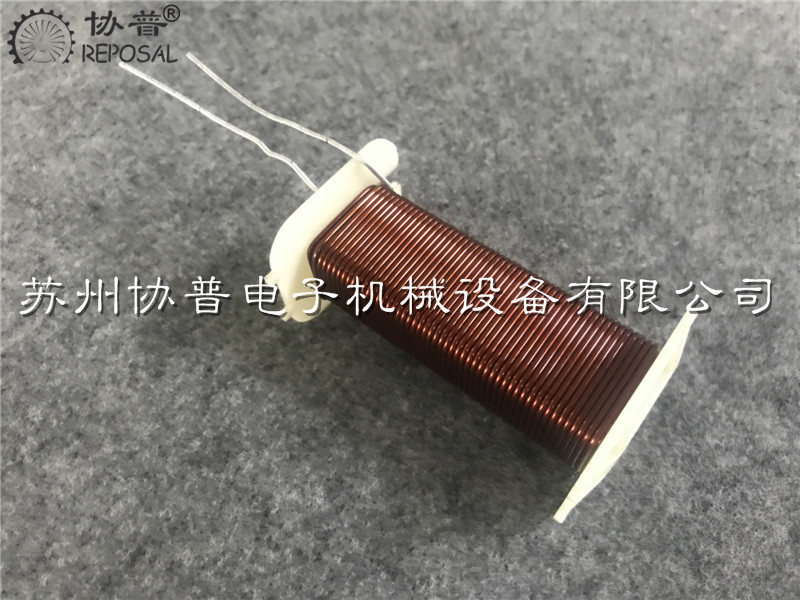

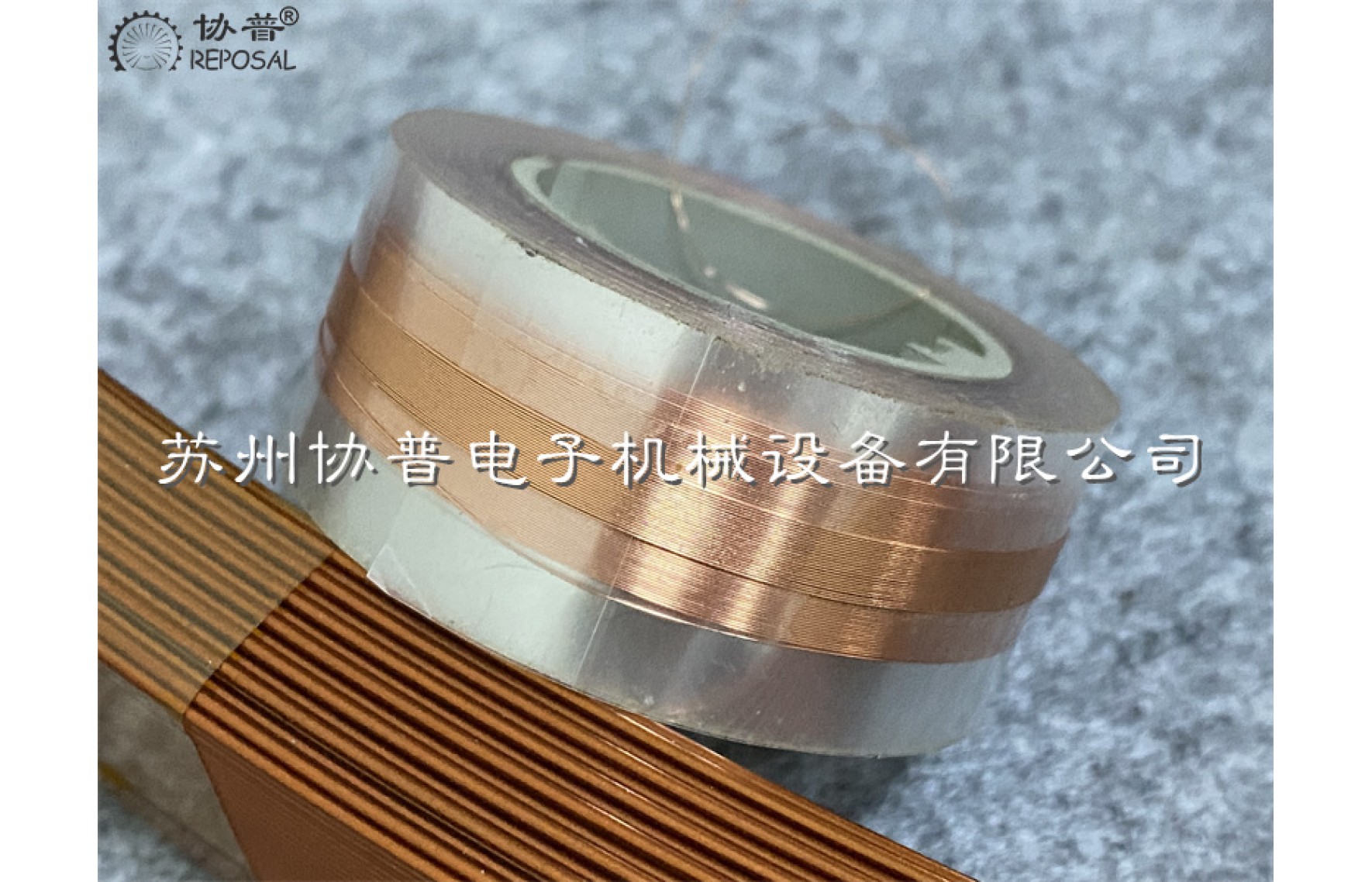

In the structure of the high frequency and high voltage power supply winding interlayer insulation type high voltage packet coil, it is necessary to leave an insulation gap between the enameled wire layer and the enameled wire layer, and then arrange the insulating paper tape in the insulation gap, the insulating paper tape is called the insulation layer. Therefore, the high frequency and high voltage power supply winding interlayer insulated high voltage pack coil is usually wound in layers, especially the high frequency and high voltage power supply high voltage winding interlayer insulated high voltage pack coil, the conductor is usually a small cross-section of aluminum or copper, the enameled wire is wrapped in layers of insulation paper, and the two ends of the enameled wire layer also need to be filled with insulation tape. This makes the process of the high-voltage coil winding machine different from the general winding equipment.

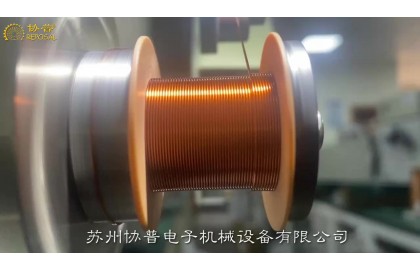

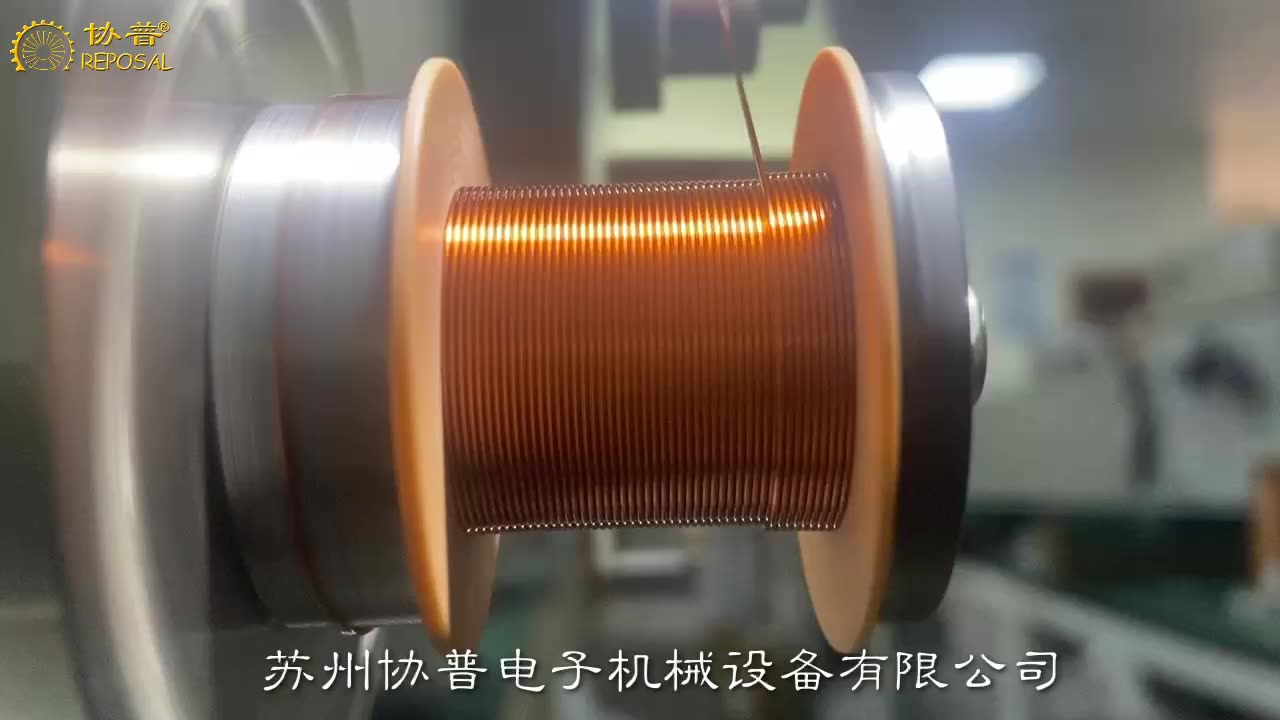

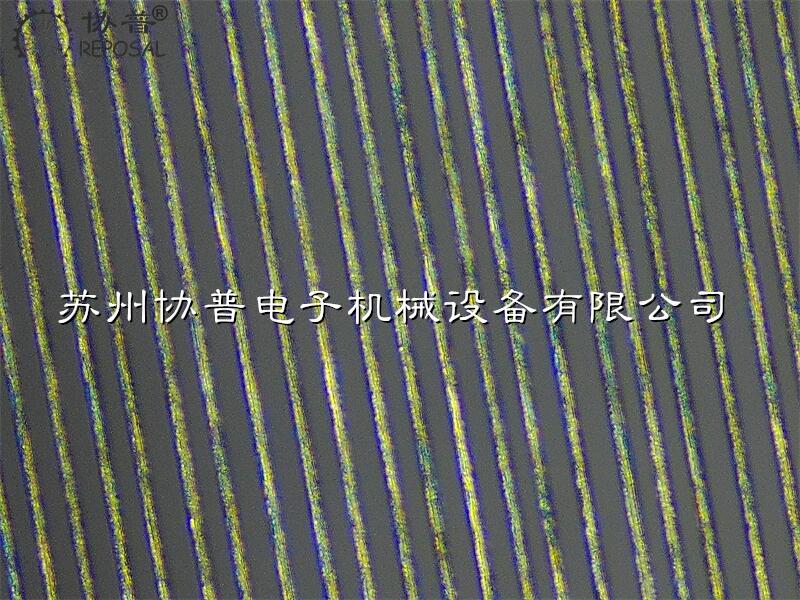

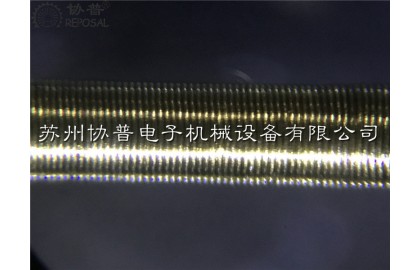

First, the enameled wire is uncoiled and sent to the spindle die frame through the enameled wire winding mechanism. During the transmission of the enameled wire, the rod is oscillated to adjust the coupling between the tensioning force and speed of the enameled wire. The spindle motor drives the spindle to wind the enameled wire on the spindle die frame. Then the insulating tape begins to uncoil and is sent to the spindle mold through the insulating tape winding mechanism. During the transmission of the insulating tape, multiple rolling rods in the insulating tape winding mechanism cooperate with each other to adjust the tension of the insulating tape enameled wire. Finally, the first layer of enameled wire and insulated tape is wound and wired through multiple motors on the spindle of the high-frequency and high-voltage power supply. After the winding of the insulated HVDC coil between the first layer is completed, the motor reversal of the enameled wire part is controlled to wind the insulated HVDC coil between the next layer.

The control of the tension force of enameled-wire directly affects the densification between layers of the winding wires of high frequency and high voltage power supply. In actual projects, machining accuracy, sensing device performance, control system closed loop, controller of the wire tension control function is perfect and other factors have great influence on the wire tension control, different factors have different effects on the wire tension control. In the production process of the high pressure coil winding machine, the influencing factors of the tension control of enamelled wire are as follows:

one Coil diameter change: In the process of winding up and unwinding the winding machine of high frequency and high voltage power supply, the radius of the coil will change in real time. If the angular speed of the coil stick remains unchanged, the tension of the enameled wire will increase when the winding diameter changes, and the tension of the enameled wire will decrease when the winding diameter increases.

two The tension of enameled wire fluctuates when rewinding reel starts and stops, acceleration and deceleration: In the production process of the lamellar coil winding machine, the shaft will frequently start and stop, acceleration and deceleration operations, which will cause continuous fluctuations in the tension of the enameled wire. The tension of the enameled wire needs to be adjusted by the speed of the rewinding rod and the tension mechanism of the enameled wire.

Three. The manufacturing accuracy of the winding machine has a great influence on the control of the tensioning force of the enameled wire, the deformation degree of the rod barrel, the installation accuracy of the bearing, the dynamic balance treatment of the rotating parts, and the transfer accuracy of the key parts. Only when the manufacturing level of the high pressure coil winding machine reaches a certain precision, the controller will have an obvious effect on the stability of the tension force of the enameled wire.

The positive and negative rotation of the motor: in the layer-wound high pressure packet coil winding machine, because the characteristics of the layer-wound high pressure packet coil winding machine need to carry out frequent positive and negative rotation operation on the spindle motor, which will produce large enameled wire tension disturbance, it is necessary to choose a motor with high stability and fast response speed as the actuator.

Five. Hardware performance: The tensioning force sensor of enameled wire is an important hardware in the process of tensioning force control of enameled wire. It is mainly used to obtain the tensioning force data of enameled wire and insulated tape during the process of winding and laying. The controller and the tensioning force mechanism of enameled wire are the main devices for adjusting the tensioning force of enameled wire. The performance of these devices has a great influence on the control system of the whole high-voltage coil winding machine, which is embodied in the stability performance, response speed, position accuracy, efficiency characteristics and so on.

In the process of automatic wiring, in order to realize the close arrangement and layering between the turns of the layer insulated high voltage pack, the close cooperation between the wiring control technology and the multi-axis control technology is needed. Firstly, we will design the scheme of the wiring control system, and study the lagging Angle of wiring and the trajectory of wiring. Then the multi-motor cooperative control algorithm is compared and analyzed, and the best control algorithm is selected. Finally, the multi-motor cooperative control scheme of winding machine is designed.

The relative adjustment of the arrangement mechanism and the position of the winding and the accurate control of the lag Angle are the key factors to ensure the density of the winding layer in the process of the winding machine. We will study the working principle of the wiring mechanism, design the automatic wiring control scheme of the winding machine, and study the lagging Angle of the wiring and the trajectory of the wiring.

A rotary encoder with high precision is installed on the spindle of the high frequency and high voltage power coil winding machine, which is used to measure the rotation Angle of the spindle when the winding machine is running, and the detected data is amplified and transmitted to the controller. After fine processing, the controller sends a pulse signal to the wiring motor to drive the wiring mechanism. The spindle is aligned with the speed of the wiring mechanism to realize the speed coupling of winding and wiring.

The control of the tension force of the enameled wire is controlled by the winding spokes of the enameled wire mechanism and the rolling mill of the oscillating mill. The control of the tension force of the enameled wire of the insulating paper tape is controlled by the winding mill of the insulating tape mechanism, the electromagnetic brake mill and the main speed bar. In the actual winding process of the high pressure coil winding machine, the enameled wire mechanism and the absolute edge tape mechanism of the winding machine need to keep the tension of the enameled wire constant during the transmission of the enameled wire and the insulation tape, and cooperate with the wiring mechanism to arrange the wiring layer on the main shaft when the enameled wire and the insulation tape are transmitted to the main shaft. In the process of wiring layer of the winding machine, in addition to the close cooperation of each device, it is also necessary to process the signal feedback from the encoder.

In the automatic wiring control scheme, the main controller controls the cooperative operation of the electric unit through the drive module, and the electric unit controls the winding mechanism of the enameled wire and the insulating tape. The main shaft and the wiring mechanism cooperate with each other to do the translation of the X, Y and Z axes in the space of the main shaft, and simultaneously wind the enameled wire and the insulating tape in layers. Finally, the coders feed back the data such as the number of layers wound, the total length of the coil wound, the lag Angle and the spatial position of the coil in real time, and adjust the acceleration and deceleration of each axis according to the logic of the control algorithm, so as to ensure the accuracy of the automatic wiring system.

In the process of winding interlayer insulated high voltage packet coil, the tension force of enameled wire in the longitudinal axis is greater than the support force and friction force between diameters, resulting in wire tension, even fracture or jumper. Too small lag Angle will cause the component force of the tension force on the enameled wire in the direction of the longitudinal axis to be too small, resulting in a large gap between the turns of the interlayer insulated high voltage pack coil. Therefore, in order to obtain tightly arranged interlayer insulated HVDC coils, it is necessary to limit the variation range of line lag Angle.

The automatic wiring process of the high-voltage coil winding machine has higher requirements for the motor control algorithm. The high frequency and high voltage power supply winding machine needs strict control logic and motor control algorithm with high synchronization rate, small error and fast response speed in order to realize the close coordination between winding and wiring, accurate control of lagging Angle and wiring trajectory, and tight arrangement of interlayer insulated high voltage pack coil. Therefore, it is necessary for the axis motor to cooperate and drive the actuator to cooperate with each other to complete the automatic winding and arrangement of the insulated high-voltage coil between the layers of the high-frequency and high-voltage power supply. We analyzed several common multi-motor cooperative control structures in the market, provided the parameter simulation environment, carried out MATLAB simulation, selected the best motor cooperative control algorithm by comparison, and designed the multi-motor cooperative control scheme of the layer wound high pressure pack coil winding machine.

We have completed the design of the automatic wiring system of the high pressure pack winding machine, analyzed the optimal range of the lag Angle of the wiring, and studied the winding trajectory of the high pressure pack winding machine in detail. Due to the high requirements of motor control algorithm in the process of wiring up, several multi-motor cooperative control algorithms were compared and analyzed, and experimental parameters were selected according to the actual requirements of the project to carry out MATLAB simulation experiments, which verified that the bias coupling control algorithm has advantages such as small synchronization error and fast response speed. The multi-motor cooperative control scheme of the winding machine is designed based on the deviation coupling control.

After verification and optimization, we first designed the rewinding and rewinding system of the insulation layer of the high pressure packet coil winder, and carried on the mathematical modeling of the system. Then through the study of the changing law of the speed, acceleration and winding radius of the insulated tape during the winding process, the control scheme of the tension force of the enameled wire and the design of the fuzzy controller are completed. The results show that the torque of the unwinding rod, the torque of the electromagnetic brake rod and the speed of the main speed rod can buffer the change of the tension of the insulated wire and compensate the tension of the enameled wire of the interlayer insulated high voltage pack coil. The adjusting ability of the control system based on fuzzy PID for the tension of enameled wire and its inhibiting effect on the tension fluctuation of enameled wire are verified. In addition, the speed step interference is introduced to carry out simulation experiments. The experimental results show that the fuzzy PID wire tension control scheme has faster setting time and lower steady-state error than the conventional PID wire tension control scheme, and the system can maintain stability under different reference wire tension forces and transmission speeds.

Aiming at the problem of backward control technology and low degree of automation, the company has designed a complete set of control system for the tensioning force of the enamoured wire of the laminated high pressure coil winding machine. Through MATLAB simulation experiment, it is verified that the system can control the tension force of the insulated tape accurately, and the control performance of the system is stable and the degree of automation is high. The company's conclusions are as follows:

First, the design of the automatic wiring control system of the high-voltage coil winding machine, the analysis of the lag Angle range of the wiring and the planning of the wiring trajectory are completed. In view of the high requirements of motor control algorithm in the process of winding machine wiring, experimental parameters are selected to carry out MATLAB simulation experiments. The experimental results show that the deviation-coupled motor control algorithm has advantages of small error, fast response speed and high synchronization rate, and the design of motor coordination scheme based on deviation-coupled control is completed. Increasing the coordination between shafts ensures the quality of interlayer insulated high voltage pack coil arrangement.

Secondly, the winding system model of the insulation layer of the high pressure packet winding machine is established, and the changing rules of the linear velocity, acceleration and winding radius of the insulation belt are obtained. Aiming at the problem that the continuous fluctuation of the tension force of the wrapped enameled wire will occur due to the reduction of the radius of the unwinding rod and the periodic swing during the winding process, multiple sets of simulation experiments were carried out under different reference tension forces of the enameled wire. The experimental results show that The torque of the unwinding rod, the torque of the electromagnetic brake rod and the speed of the main speed rod can buffer the tension of the insulated wire and compensate the tension of the insulated wire in the interlayer insulated high voltage pack coil. The adjustment ability of the fuzzy PID-based control system for the tension of the enameled wire and the inhibiting effect on the tension fluctuation of the enameled wire are verified.

Third, to solve the problem of large enameled wire tension disturbance caused by frequent shaft start-stop and acceleration and deceleration in the production process of the winding machine, step speed interference was introduced under different reference enameled wire tension forces, and multi-group comparative simulation experiments with traditional PID control were conducted. The experimental results showed that, in the steady state and acceleration stages, The fuzzy PID wire tension control scheme has faster setting time and lower steady-state error than the conventional PID wire tension control scheme. The system can maintain stability under different reference wire tension and transmission speed.

Fourthly, the software and hardware design of the high-voltage coil winding machine is completed. The hardware control system composed of Befo controller, servo motor, position and enamelled wire tensioning force sensor is designed according to the control requirements of the high pressure coil winding machine. The software flow chart and the monitoring interface of the upper computer are designed.

The research results given by the company in the layer wound high pressure packet winding machine are not limited to the laboratory. The layer wound high pressure packet winding machine developed by the company has not only been tested by the prototype, but also has been put on the market and has been unanimously affirmed, breaking the foreign monopoly on the core technology, and realizing the autonomous control of the automatic layer wound high pressure packet winding machine technology.