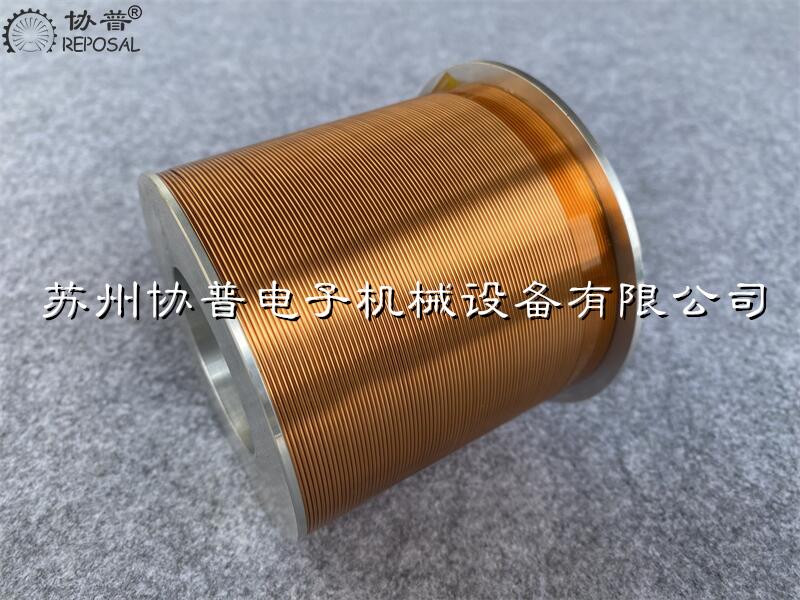

REPOSAL ® winding machine to overcome guidance fiber wire winding process difficulties

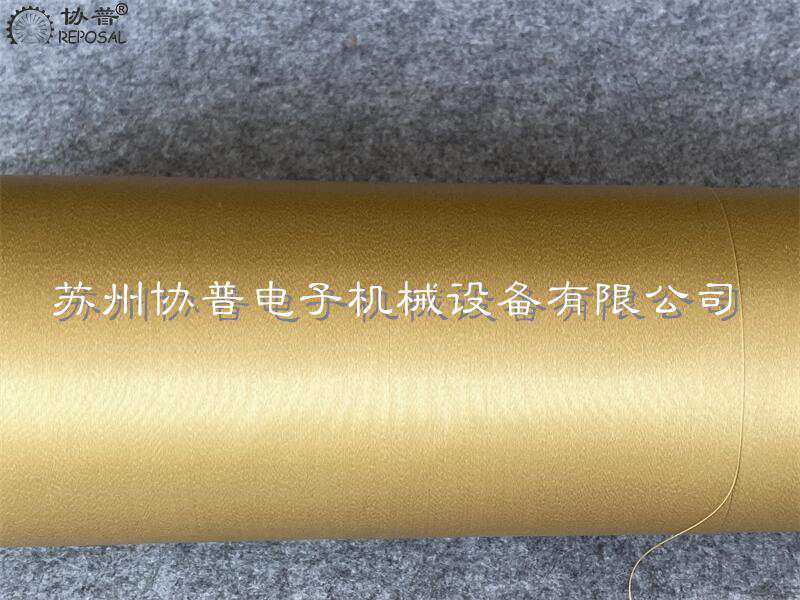

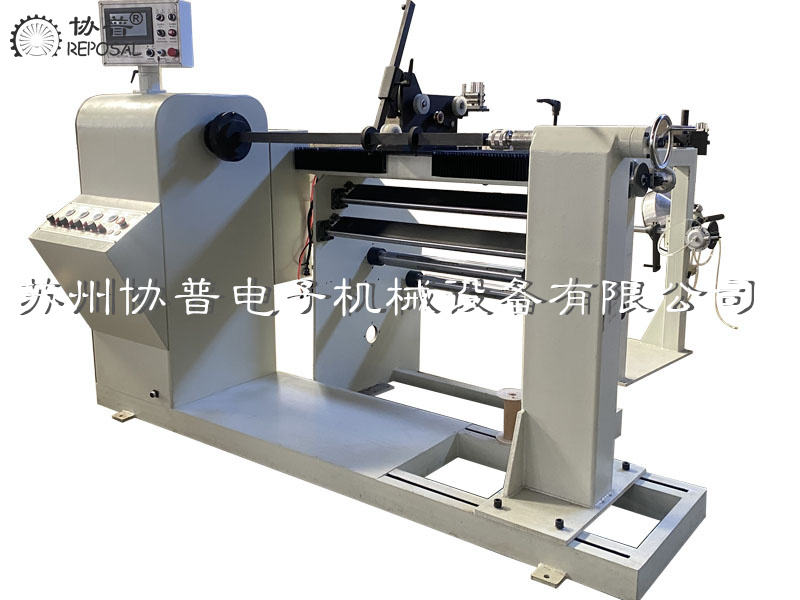

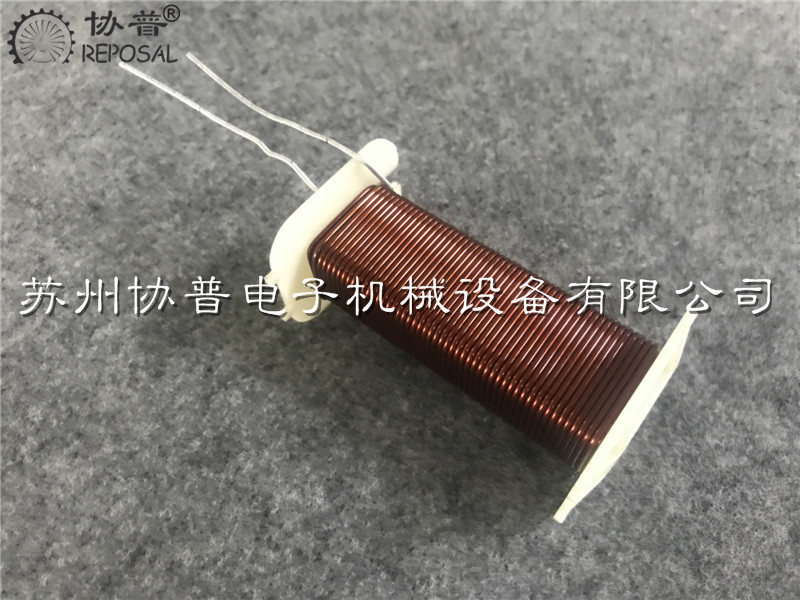

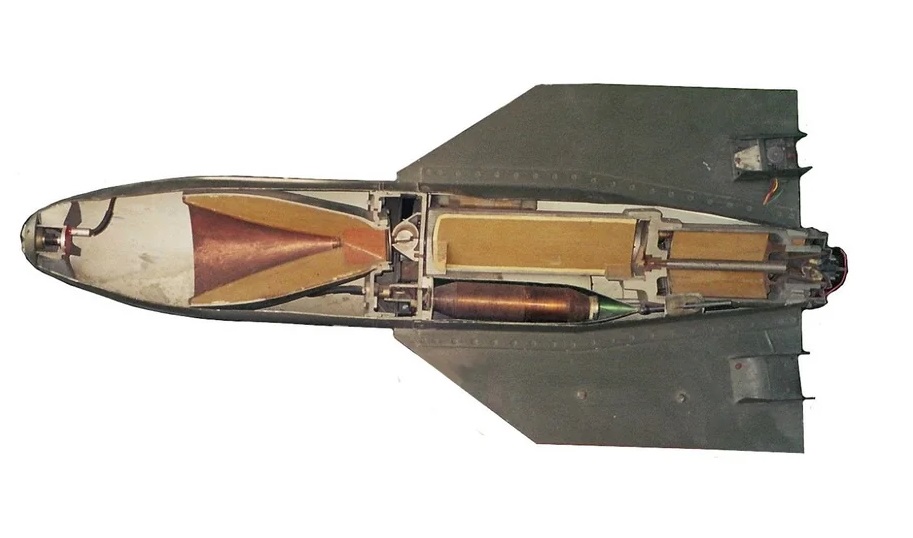

Optical fiber has many advantages, large communication capacity, long transmission distance, low fiber loss, anti-electromagnetic interference, no radiation, long life and so on, so it is widely used in the field of communication, especially. Guidance communication has an excellent application prospect, but the guided fiber wire package needs to be wound long distance without defects, but because the surface of the fiber is smooth, brittle and easy to break, as well as the residual stress generated by the micro bending will make the signal attenuation, so it is more difficult to wind than other fibers, making long distance fast fiber automatic winding without defects has become a major issue. REPOSAL® winding machine, as a professional winding process solution provider, has been developing process research on precision winding of guided fiber wire packages for many years. Good progress has been made and REPOSAL® special winding machine for guidance fiber wire wrap developed by the winding machine can set reliable process instruction information according to process requirements and accurately execute control commands to finally finish the long distance guidance fiber wire wrap without defects. In the whole research project, we focus on solving three problems of guidance fiber optic wire wrapping system: tension control. Winding system, feeder system, and expand as follows.

Tension control: optical fiber surface friction is very low, resulting in very easy to slide, and the fiber is brittle, easy to break; In the winding process, the optical fiber winding machine needs to be wound under constant tension, otherwise it is difficult to wind according to the pattern, which will generate residual tension in each turn. At the same time, in the process of winding layer by layer, the centripetal pressure between layers will be caused. The more layers, the compressive stress of the inner layer winding will be further increased. Will bring greater transmission loss. Therefore, the fiber winding process can only be controlled using the lowest possible tension. Therefore, tension control is crucial and very difficult in the whole winding process.

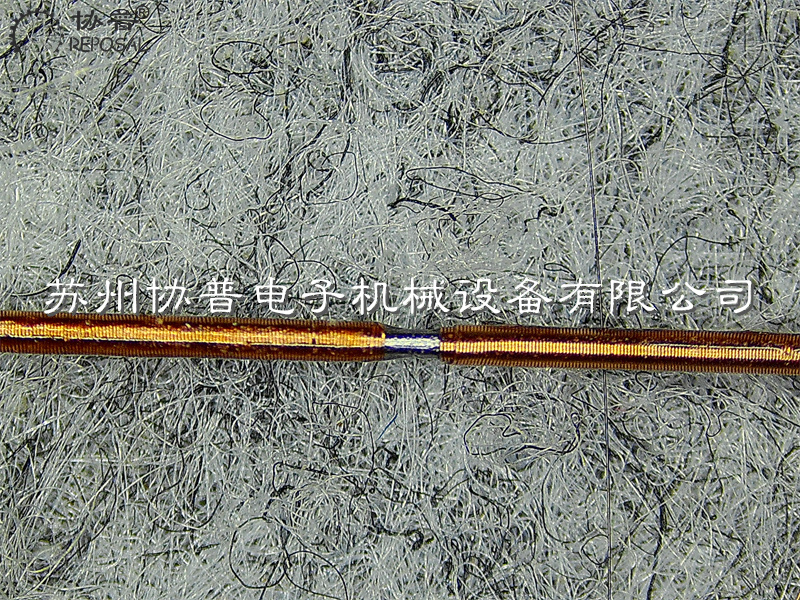

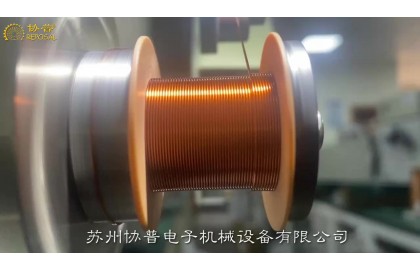

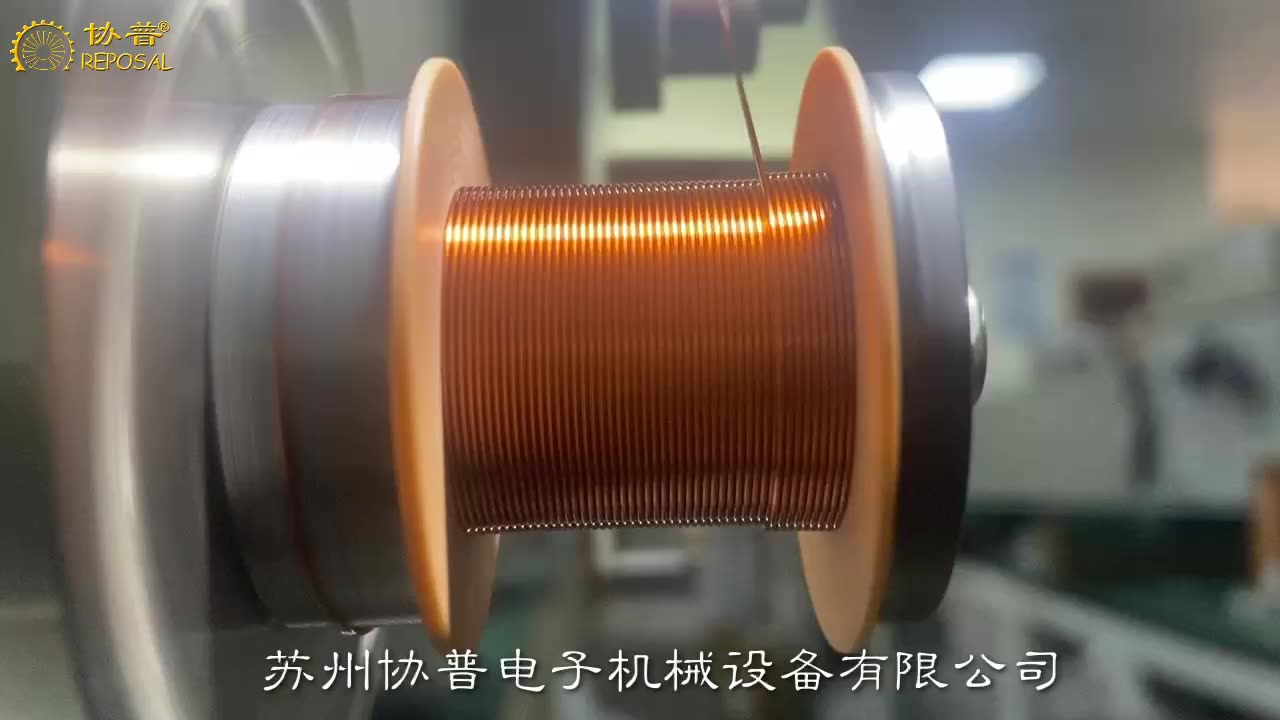

During the winding process of the optical fiber, entanglement and folding may cause damage to the optical fiber. Such damage may even lead to the inability to complete the winding. During the winding process of the optical fiber winding machine, the linear speed of the optical fiber winding should be kept as even as possible. This is also conducive to the stability of fiber tension. Optical fiber wire speed is determined by the spindle speed of the optical fiber winding machine, the spindle of the optical fiber winding machine is constant angular speed, but with the optical fiber layer by layer winding, in fact, the radius increases, so we must adjust the angular speed of the optical fiber winding machine according to the real-time radius to keep the linear speed of the optical fiber winding. The feed bobbin must adjust its own speed with the line speed around the bobbin (circular speed). Its linear velocity is also determined by its real time radius and angular velocity.

Through test analysis, it is concluded that different tension sizes have the following effects respectively. If the tension is too small, correct fiber winding cannot be realized. If the tension is too large, the residual stress is large, especially the interlaminar centripetal pressure, resulting in signal attenuation. Therefore, only the tension between the first two conditions, that is, a certain tension is required to achieve correct fiber winding, and as far as possible to the residual stress controller acceptable range.

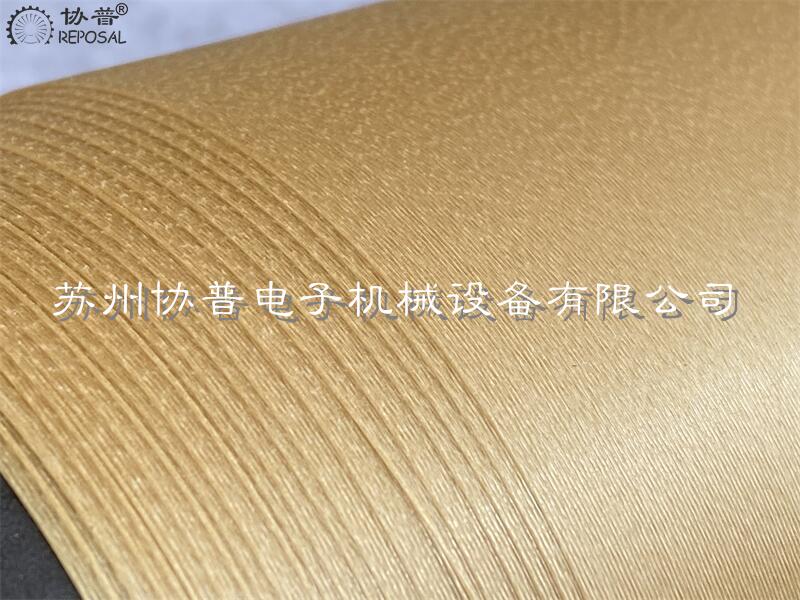

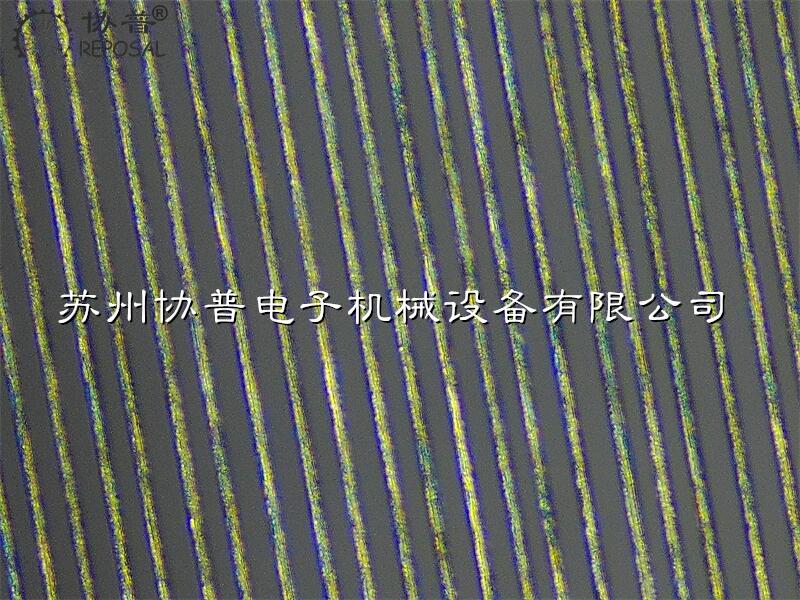

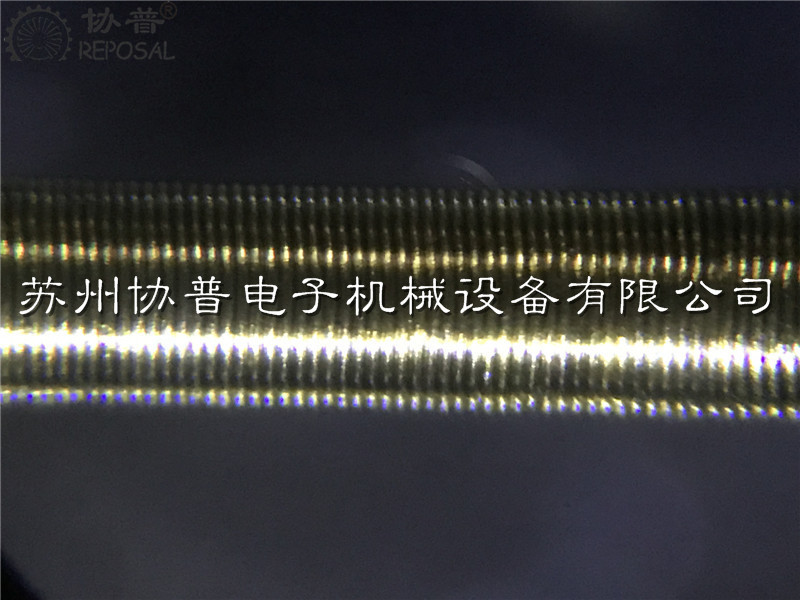

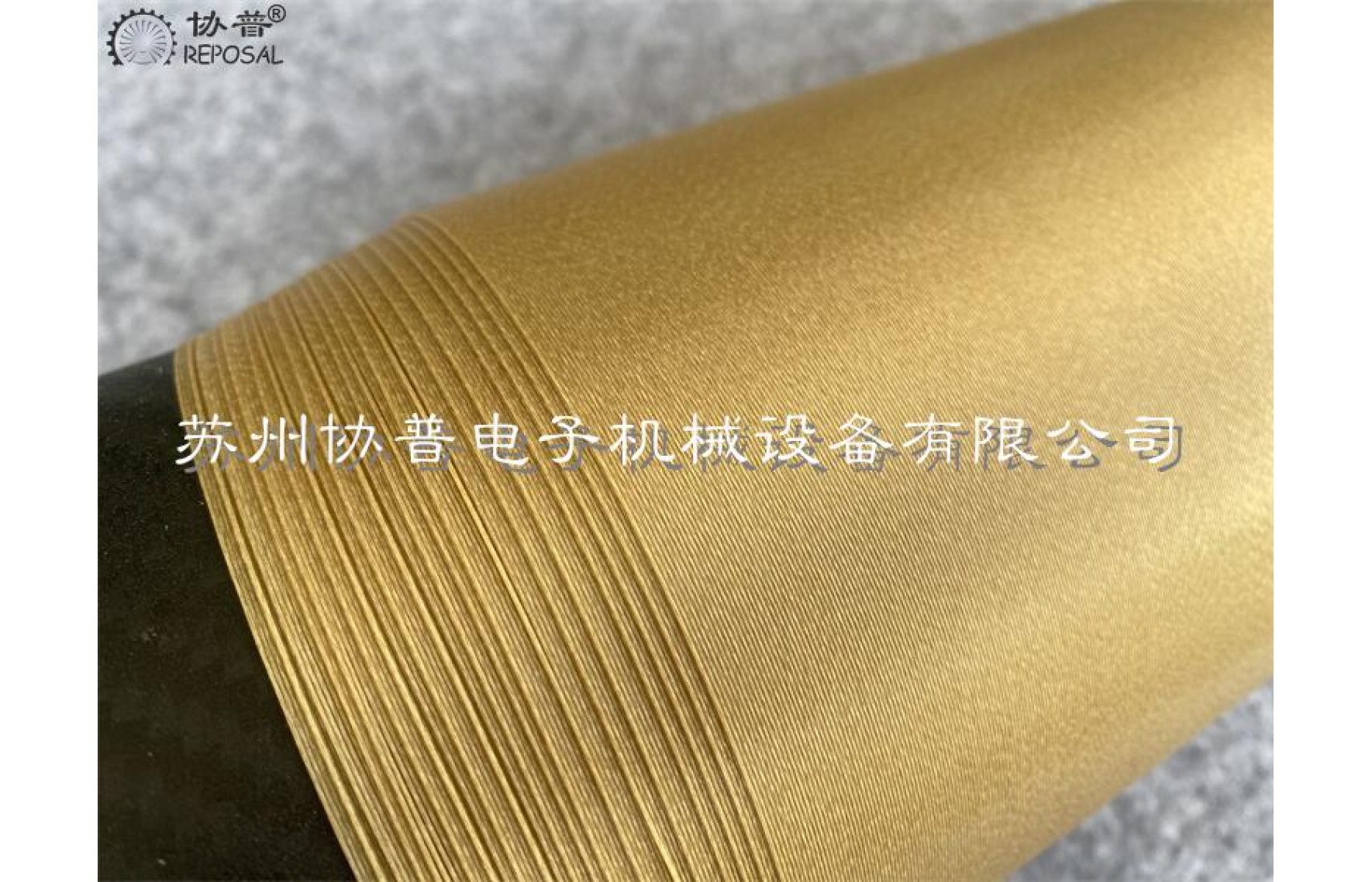

There is also the gap of fiber winding, that is, the gap between turns of fiber winding. Of course, the optimal situation is that turns are close to turns without gap or the gap is minimum. When the gap between turns of fiber is minimum, the next layer of fiber can be prevented from turning into the previous layer of fiber. At the same time, when the turns are close to the turns without gap or the gap is the smallest, it can also be conducive to the entire fiber winding layer smooth and flat, so that the winding of the second layer of fiber does not have micro-bending defects, but also can make the winding compact and the volume of the smallest.

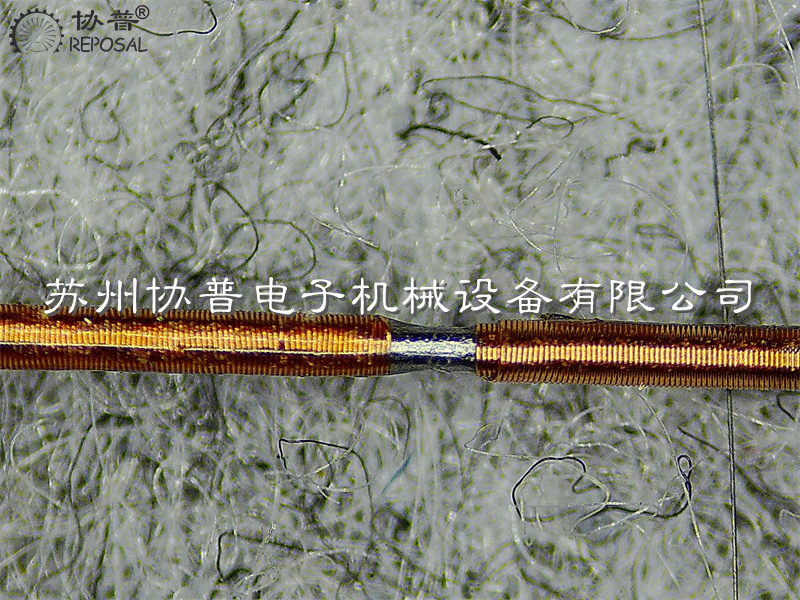

But in the actual winding process, restricted by the optical fiber manufacturing process, the machinery of the optical fiber winding machine and the control accuracy, it is obviously impossible to do so. Our solution is to maintain a relatively constant lag Angle between the feeder point and the falling point during the winding of the fiber, and this lag Angle should be controlled within a relatively stable and reasonable range, and the lag Angle is too small. Then the turns are not tight enough and the gap increases. If the hysteresis Angle is too large, it will easily cause winding under the action of tension.

The hysteresis Angle is determined by two factors. The first factor is the position difference between the feeder point and the fall point in the axial direction. The second factor is the radial distance between the feeder point and the drop line.

The winding turns wind up the axis layer by layer, the winding diameter of the line increases layer by layer, and the distance between the feeder point and the falling line point also changes accordingly. Therefore, when we design the process, the feeder point needs to move backward accordingly according to the layer by layer winding.

The repeated winding test of optical fiber winding machine shows that the maximum lag Angle allowed to avoid the winding phenomenon is small and related to the tension. Under the condition of constant tension, the axial displacement accuracy is very high. We use AC servo motor to achieve this movement. The lag Angle can be acquired by Angle sensor, which can be used to control and adjust the position of the feeder point relative to the falling line point to obtain a stable lag Angle.

During the winding process, the drop point of the winding should be kept in a fixed position, generally at the top of the winding. Because the movement of the top point is actually a change in the winding speed, but in the actual winding process of the optical fiber winding machine, we will find that the falling line point will move layer by layer as an involute, there is a view that this is because in the case of constant angular speed around the spool, the fiber linear speed will increase the winding diameter in the process of winding layer by layer, resulting in the change of linear speed. However, the actual situation is that in the process of winding layer by layer, the falling line point is also the intersection point of the upper and lower layers. The height of this crossing point is higher than that of other guiding areas in the circumferential range. However, under the action of tension, the optical fiber will naturally slip from the height to the lower, so the falling line point of the layer by layer presents the involute line.

In order to ensure the stability of optical fiber winding, both ends of each layer should have a certain number of turns retraction maximum, generally 2-3 turns. This action is realized by the rapid acceleration of the winding axial motion. When the optical fiber is wound up, the winding glaze immediately rears back. Within one week of winding around the axis, it reverses the hysteresis Angle and then begins the second layer of winding.

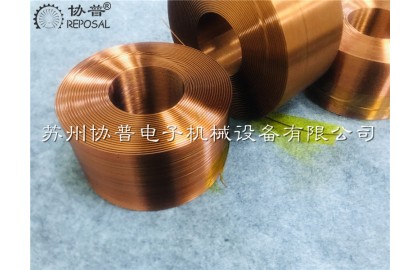

Feeder section

Since the fiber winding machine can only use a low tension in the winding process, and the fiber on the supply coil is loosely wound, the tension changes greatly when the release. In order to eliminate this adverse effect and match the tension control system, the feeder part is designed as follows: the feed shaft is driven by a servo motor, and then the tension sensor dynamically adjusts the speed of the feed shaft in time according to the measured tension, so as to maintain a stable tension. Fiber tension, as the main parameter in winding process, is very important for long distance error-free winding of guidance fiber.

REPOSAL® winding machine as a professional winding process solution provider, Reposal ® winding machine has made continuous exploration and testing on the precision winding process of guided optical fiber wire package, cooperated closely with industry users, and successfully solved the above problems, which has been well received by users after in-depth cooperation.