General debugging method of winding machine

General debugging method of winding machine

Some people look at the winding machine and feel a bit like a lathe, but in fact the winding machine has to wind a neat coil. Compared with the smoothness of the lathe, it is much more complicated, so we will find that the lathe has a long time ago The national standard has quantitative standards for its various indicators, but the winding quality of the winding machine has many condensing factors and it is difficult to quantify.

It is precisely because of the above reasons that at first I feel that the winding machine should be very easy to debug, but after the facts, I will be a little frustrated. Although the winding machine debugging is indeed more complicated than imagined, but if we master the basic laws After that, it's not difficult to practice more.

First of all, we must have a preliminary understanding of the structure of the winding machine, otherwise, we are not familiar with the structure of the winding machine, and there is no professional technical personnel training. Automatic debugging of the winding machine will be incompetent.

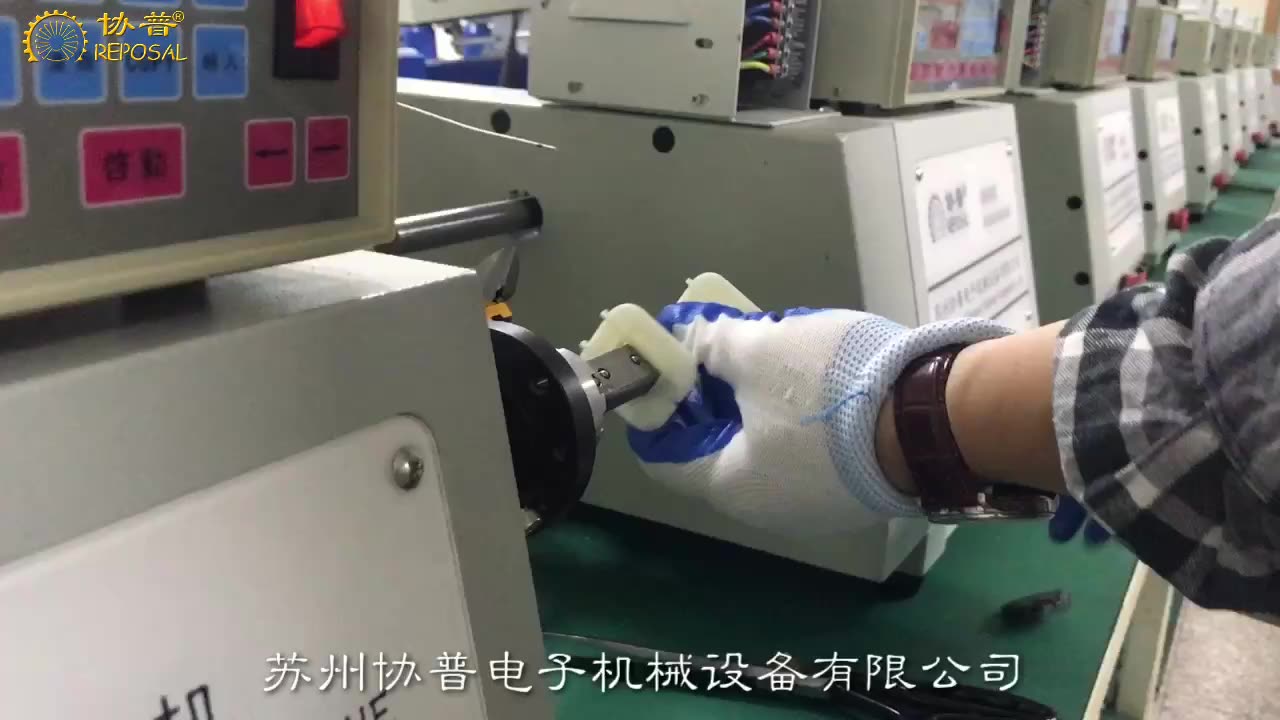

The basic equipment of the winding machine is composed of mechanical parts and electrical control systems. However, with the rapid development of science and technology, modern automatic winding machines integrate electrical control, sensing technology, pneumatic and mechanical transmission, photoelectric detection and many other technologies, so they are debugged. Compared with other electronic processing equipment, it will be more difficult and sophisticated. Xiepu has developed and produced winding machines for many years, and has rich experience in the use and debugging of winding equipment. Here, we will give you a brief introduction. I believe we only After mastering the basic concepts and methods, and after more practice, you can debug the coil that you are satisfied with.

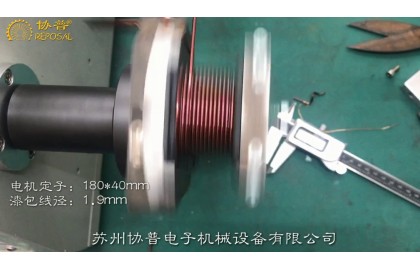

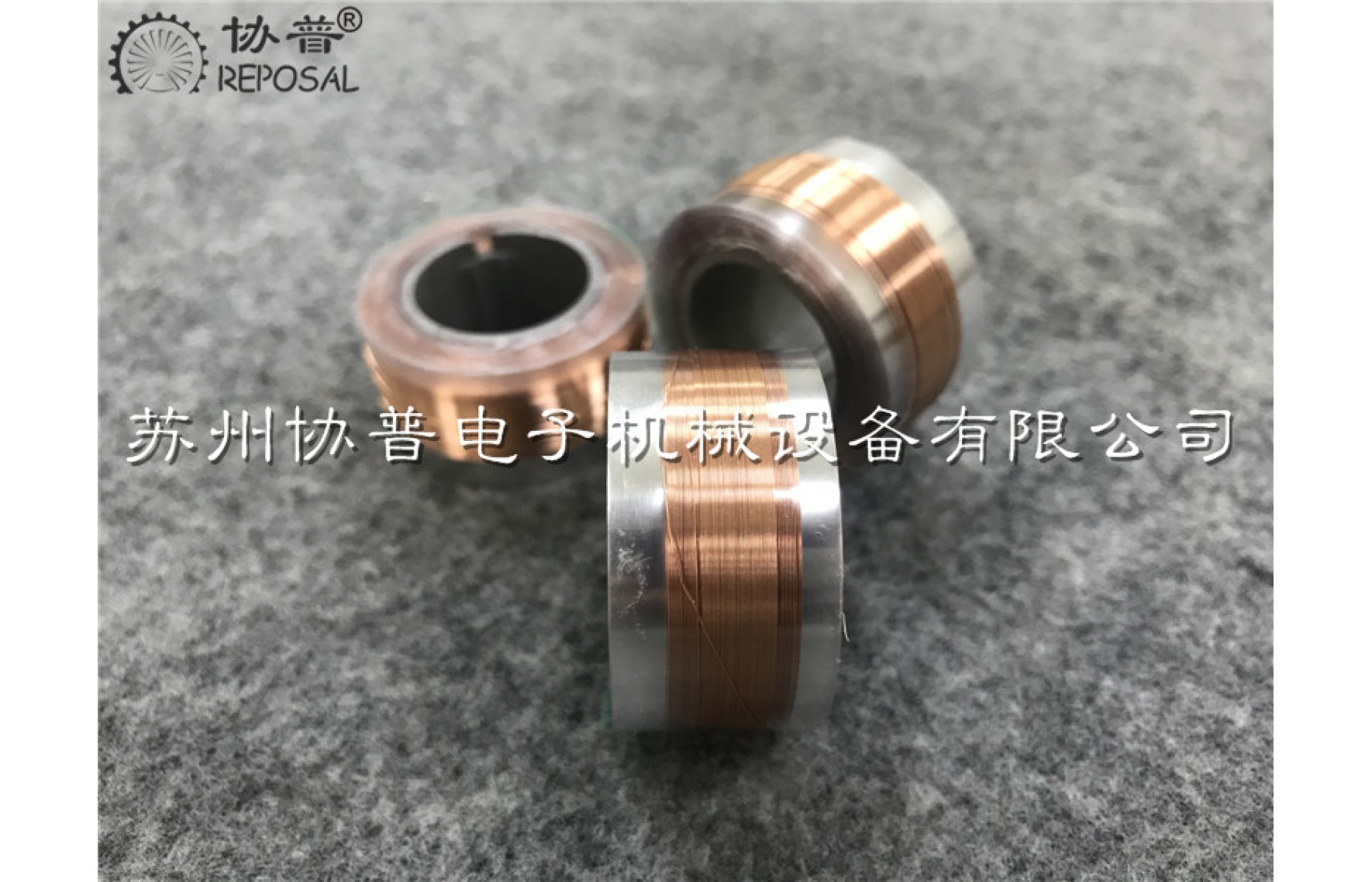

The three main parameters of the winding machine: the starting position, the diameter of the enameled wire, and the winding width are the three most important winding parameters of the winding machine, which are commonly used in the skeleton coil.

1. How to set the starting position? Where is the starting position of the bobbin coil? In fact, there is no fixed position at the starting point of the winding on the skeleton. The position and the coil end are determined by the coil model. Generally speaking, the specific starting position and value can be measured as long as the measurement function of the equipment control system is used; technical personnel also The value can be measured manually, and the specific position is used as a reference point to use a ruler for actual measurement. When setting this point, pay attention to the specific winding direction of the coil.

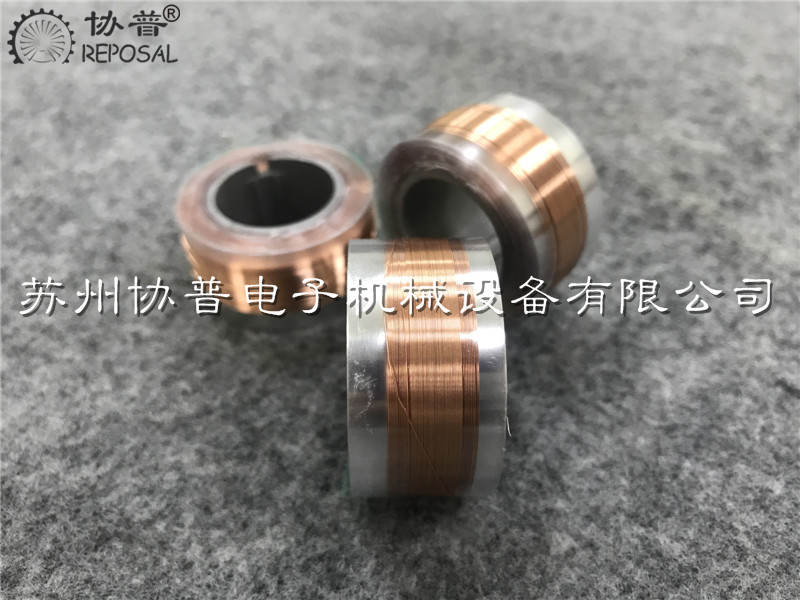

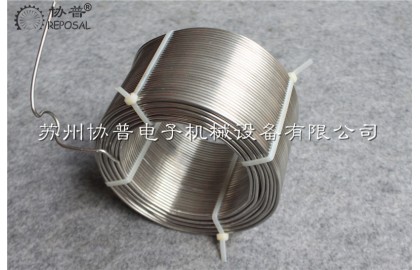

2. The specific setting of the diameter of enameled wire. The enameled wire used in daily use has different diameters. Different enameled wire specification settings will produce different wiring effects. When using different material enameled wires, pay attention to correcting the specific value of the wire diameter, so that the copper wire will not be deformed. .

3. Setting the winding width value. We can understand the value from the winding start point to the winding end point. Usually, the winding length of the coil can be known by the value straight. Of course, the small deformation caused by the applied force must be considered when setting, which will affect the winding width to determine the production. Therefore, it is necessary to use a variety of measurement methods to take the smallest value as the winding width.

4. For the types and characteristics of different coils, the specific number of turns, the number of folding layers and the average winding speed requirements of the product must also be well understood. The winding speed of the thick wire model should not be too fast. Quality problems such as lost steps must be strengthened to the winding machine torque when used at medium and low speeds.

5. When the wound coil is square, the winding speed of the wound coil should not be too fast, otherwise it will cause unevenness and affect the number of folding layers and turns. Moreover, the distance between the coil and the flex cable should be arranged reasonably. If it is low, it will fall into other layers. If it is high, it will jump the wire. At the same time, it should not drink the cable rack too far. If the cable rack is too far, the weight and amplitude will increase. , The tension will be unstable, and it will also affect the accuracy.