Flexible Driveline Coupling special winding machine

Flexible Driveline Coupling special winding machine

The

automobile drive shaft is the part connecting the gearbox and the drive axle.

It is a high speed rotating body, and the drive shaft connecting disk is the

part balancing the action of the drive shaft.

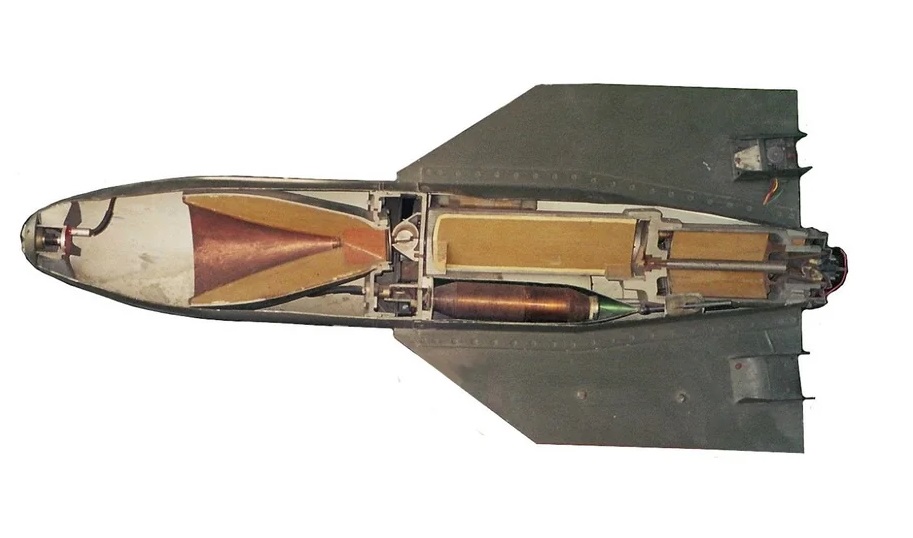

The structure of the connecting disk of the drive shaft is shown in the figure below:

It transfers the torque of the engine through the drive shaft to the executing parts.

In this process of transferring torque, the role of the flexible coupling is very important, and the flexible coupling for vehicles is a flexible rubber that can be twisted. It is a very important part of the vehicle transmission system, this flexible coupling is mainly used for rear-drive and all-wheel-drive models, it is used to transfer torque from the gearbox to the executive parts. Because it not only absorbs the impact force, reduces the interference of the transmission system, but also improves the vibration caused by the wrong Angle. Because when our vehicle is driving, the wrong Angle will cause a vibration and noise of the vehicle. This will actually have a relatively large negative impact on our safety and comfort.

And this new type of flexible coupling, it can absorb the impact force, but also can reduce the vibration caused by the wrong Angle. This is mainly because of the specially designed fiber winding in the middle of this coupling. This fiber material is made of high strength fiber silk. However, to develop a flexible coupling winding machine, the main process difficulty is not the winding strength of the fiber. Because of the winding strength of the fiber, it can be improved by increasing the number of fibers. The main difficulty of the process is the balance of the tension of multiple fiber windings.

In terms of the balance of tension between the windings. He will require that the structure of our flexible couplings should be technological, and that the winding process should be taken into account, which can be achieved by automated technology. The process requires that our fibers be wound as neatly as possible. The characteristic of fiber is that under different tension conditions, its cross-section shape after stretching is inconsistent. Then there's tension control. Under a certain tension control of the winding, after the vulcanization of the post-process, there will still be a relatively large pre-loading force. The unbalanced early warning force between the fiber pack and the fiber pack will lead to the dynamic imbalance of the rotation axis in the case of high-speed rotation, so it will aggravate the vibration during the vehicle driving.

This kind of flexible coupling has been serialized in foreign countries. In some brands of bearing manufacturers, such as SKF have been relatively mature. He not only in the rear drive and four-wheel drive intermediate application more. It can also be applied to the connection of internal combustion engine oil pump, compressor and generator. Its characteristics are highly reliable. The connection between the diesel engine and the hydraulic pump in the middle of the shovel often adopts this structure. According to statistics, more than 60% of the world's shovel are using this shaft, so its market potential and economic value is very large.As a professional winding solution provider, we are not afraid when facing these difficulties in the process, but work together with customers to understand and digest the process difficulties of the product.Step by step, through repeated research and testing. These technical problems were successfully solved. And we do it from the beginning, so that our customers can be competitive in their market.

Existing

shaft connection plate is made up of rubber vulcanization six sets of steel,

its structural strength mainly provided by the rubber, in order to increase the

structural strength, the manufacturer will before die casting vulcanized

rubber, between the six sets of steel nylon line, its technology and processing

technology is very similar to synchronous belt, between the six sets of steel

round the multi-layer nylon thread, die-casting vulcanized rubber, It's a good

reinforcement. Such as Mercedes-Benz, Ford have adopted this process.

But

after a long time of use, the drive shaft connecting disk or due to

deformation, and lead to the installation of the shaft sleeve on the drive

shaft connecting disk loosening and instability, therefore, manufacturers need

to do not change the existing mature structure, further improve the structural

strength and balance of the drive shaft connecting disk.

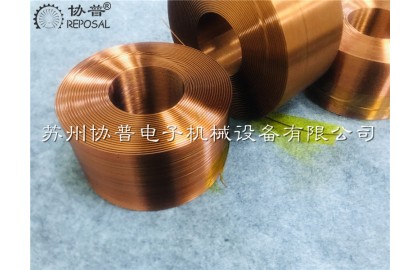

Association, winding machine and to improve the product performance has a persistent pursuit of manufacturers, the brand drive shaft connecting plate on the market for the disassembly analysis, through unremitting efforts, found the increase in space - six nylon line between steel bushing, though the quantity is more, but because the winding is not neat, before vulcanization is mess around, collapse like now. The ideal winding situation is that each nylon wire is neatly arranged and the tension is even, as shown below:

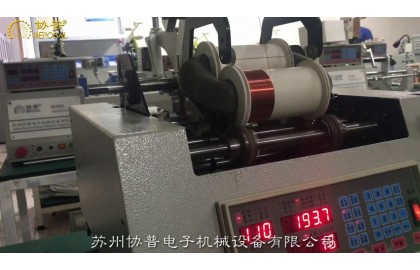

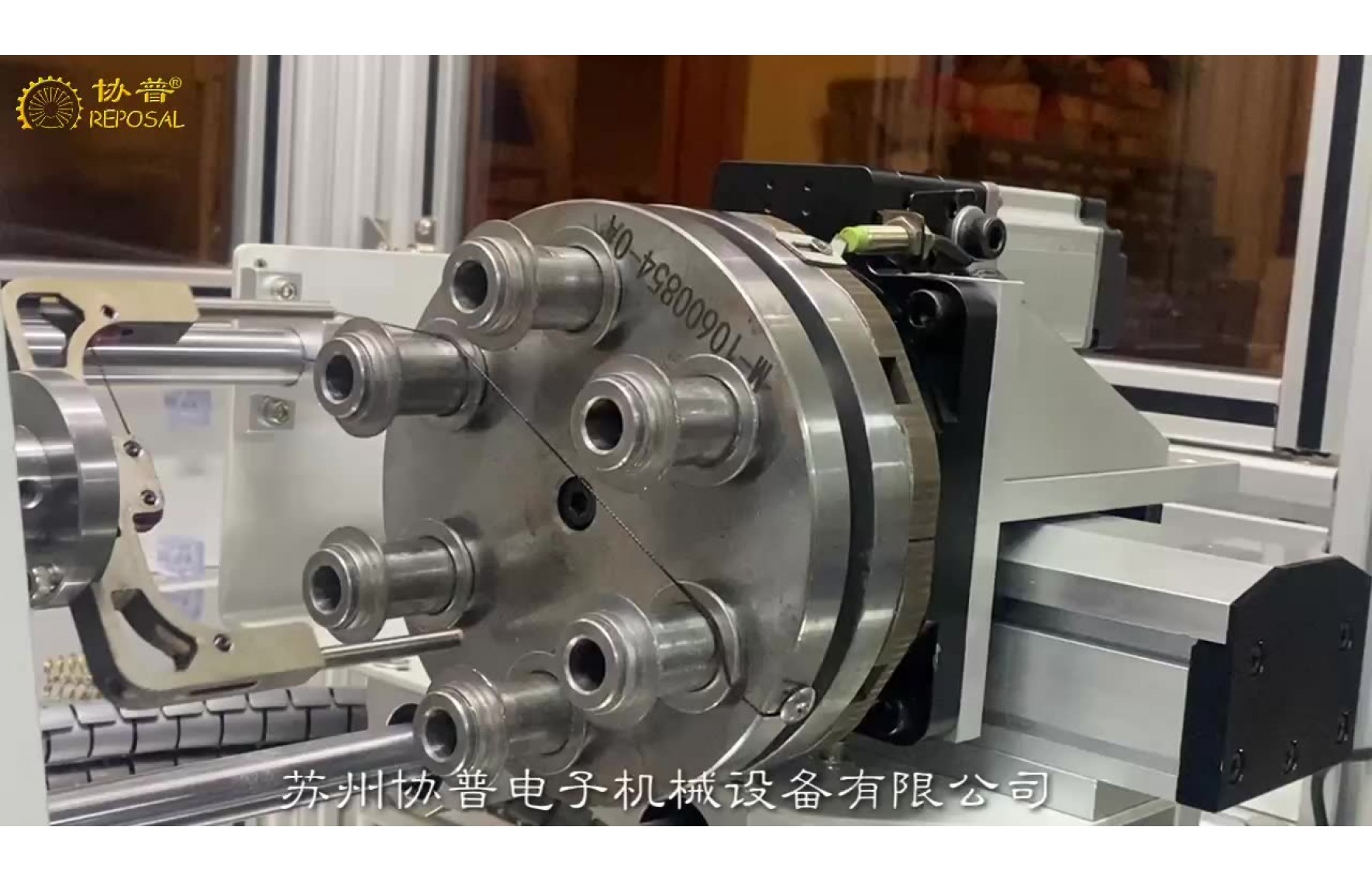

After

REPEATED DESIGN and verification, we have developed this SPECIAL equipment, the

drive shaft connecting coil wire machine, which can wind relatively neat nylon

wire in the closed slot, and can also wind neat nylon wire in the trapezoidal

arrangement in the open position.