Detailed explanation of the operation instructions of the transformer winding machine

Detailed explanation of the operation instructions of the transformer winding machine

Transformer winding machine is a special winding equipment for winding enameled coils of transformers. During the winding process of enameled coils of transformers, winding enameled wire equipment is divided according to the specifications of the transformer. Enameled wire winding machine and foil enameled coil winding machine; there are vertical winding machines and horizontal winding machines for winding enameled coils of large power transformers.

1. Structural characteristics of transformer winding machine:

1. The mechanical transmission part of the winding machine is located inside the headboard, and the electrical part is installed on the top of the headboard. The three-phase asynchronous motor is driven by the frequency converter to realize the linear change of the spindle speed.

2. The winding machine adopts stepless speed regulation, and the controller outputs 0-10V analog voltage, which is connected to the inverter. By means of percentage, there are a total of 100 gears, which can be counted accurately, and can also be counted in reverse to automatically stop.

3. The winding machine can count reversibly, and is equipped with an electromagnetic brake device to prevent reversing when winding the enameled wire to stop, and ensure that the automatic counting will not produce errors. If you need to manually reverse, you can manually press the brake button to release, and the manual rotation can also count.

2. Safety operation rules for transformer winding machine:

1. Equipment and utensils:

Winder and shelf for fixing enameled wire reels.

Enameled wire winding jig and baffle plate corresponding to the product.

Scissors, wrenches, needle nose pliers, wooden hammers and other tools.

Corresponding coil processing drawing files.

2.Material:

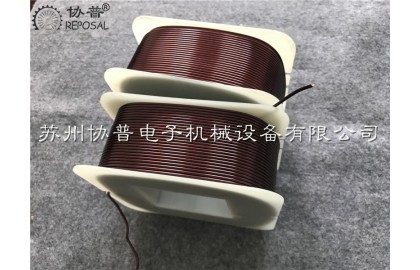

Double glass filament enameled wire or enameled enameled wire that meets the requirements of coil processing drawings.

Skeleton plate

insulating film paper

ventilation strip

white gauze

Glass cloth tape

Insulated conduit

transparent adhesive tape

3. Winding process:

Enameled wire winding jig, enameled wire, insulating film paper and ventilation strips and other materials prepared according to the coil processing drawings. Check the winding machine before use: whether the forward rotation, reverse rotation, etc. are normal. If you have any questions (especially the specifications of enameled wires), you should report to the person in charge of the winding department in time, and ask the winding department to confirm. Enameled coils are divided into enameled coils and double enameled coils. The winding methods are quite different and should be carried out according to the following methods:

Third, the winding method and steps of the transformer winding machine:

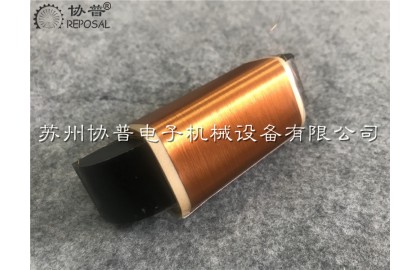

Install the winding jig, baffle plate and skeleton plate respectively, and tighten them with a wrench. Tightly wrap 3 turns of insulating film paper with the same length as the winding jig on the outside of the skeleton board. Stick with clear sticky tape so it won't come loose. Pass the enameled wire head through the baffle and reserve the length of the enameled wire head as required, and wear an insulating conduit suitable for the enameled wire gauge. Make sure the conduit does not slip out of the enameled coil. The length of the conduit outside the baffle should not be less than 60mm.

For enameled coils with end taps, the end taps shall be carried out according to the order of the coil processing drawings, and the end taps shall be arranged in sequence, with special attention to the accurate number of turns; the conduit guides the two enameled wires with the end taps in At the same time, and directly lead to the root of the tap at the end, leave a conduit of more than 60mm on the baffle, and reserve the length of the enameled wire from the tap at the end as required. In order to ensure that there is no inter-turn short circuit at the folded enameled wire at the end of the enameled wire, two layers of glass cloth tape or polyester insulating film should be wrapped at the folded enameled wire.

If the coil processing drawing requires that the enameled wire gauge should be replaced at the position of the tap at the end, the large enameled wire with the enameled wire drawn from the tap at the end should be longer than the small enameled wire, and the size of the enameled wire should be consistent with the coil processing drawing. If there are joints in the winding, they are used as external types within 8mm, and they are cut 80mm outside the baffle.

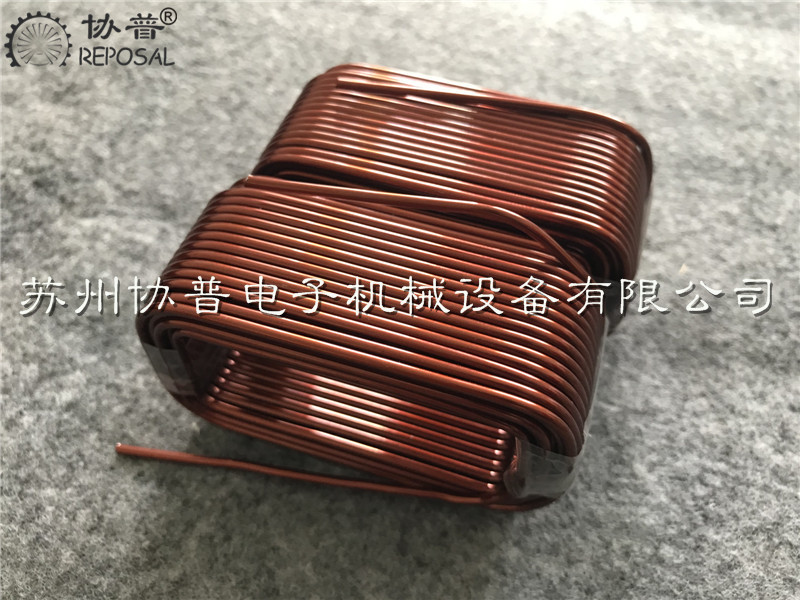

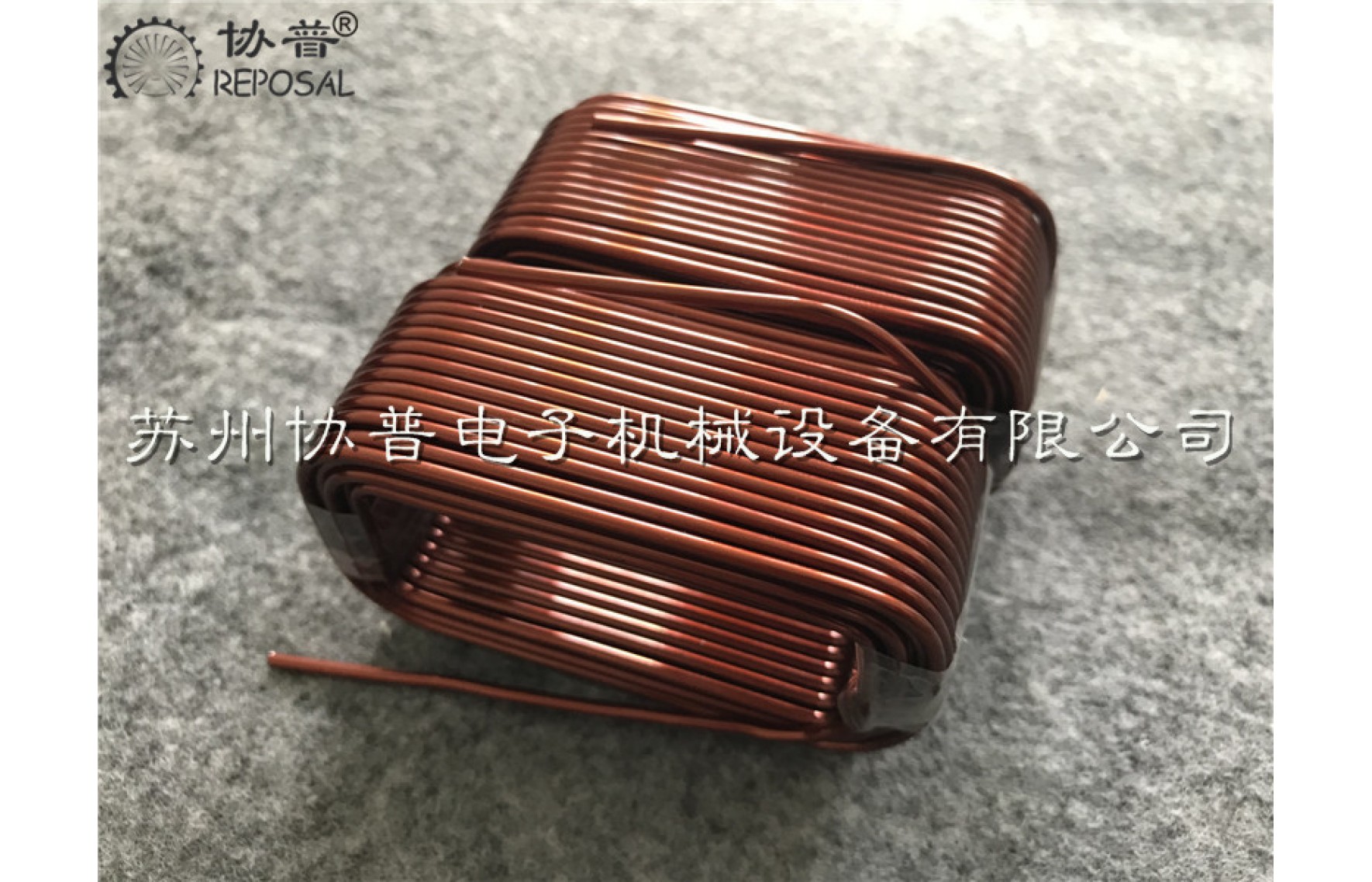

The ventilation strips should be placed on the four corners of the enameled coil. Put the ventilation strip on it, and after winding it for a few turns, hit it with a wooden hammer on both sides of each four corners of the enameled coil, so that the ventilation strip will not slide, and then continue to wind the enameled wire. When winding the secondary enameled coil (coupling enameled coil), first wind the primary enameled wire. After the primary enameled wire is wound, level it first, then wrap three and a half layers with polyester insulating film and stick the seam with transparent tape. Pad up around the secondary enameled wire to electrically isolate the primary enameled wire from the secondary enameled wire. The closest distance between the two enameled wires is not less than 3.5mm to be considered qualified around the enameled wire.

When the enameled coil is wound for the last few turns, a cable tie (white gauze tape or conduit) should be placed to facilitate the tightening of the enameled wire tail, and the cable ties should be fastened at two positions respectively. The enameled wire tail should be led to the insulating conduit in the same way as the enameled wire head. After the enameled coil is wound, level it, then remove the enameled coil and demould, cut off the excess head of the cable tie, and place the enameled coil in the designated position. The storage location should be protected from moisture and dust.

Fourth, the winding method and steps of the double enameled coil of the transformer winding machine:

The grouped enameled coil has more than two enameled coils, and the two enameled coils are connected in series. For this enameled coil, the total length of the enameled wire that needs to be used for the enameled coil should be calculated first, and the enameled wire should be removed from the plate and cut.

Install the baffle plate and the winding jig, start winding the first coil, take off the enameled coil after winding, turn it tightly at the four corners, and then install the enameled coil on the winding machine in the opposite direction, and start winding the first coil. For the second plate, the same method can be used to wind the third plate. The enameled coils with more than three coils are generally divided into two groups and wound separately. After winding, they are connected in series and combined into a group of enameled coils. After the enameled coil is wound, cut off the excess head of the enameled wire, and store it in the designated position after flattening.