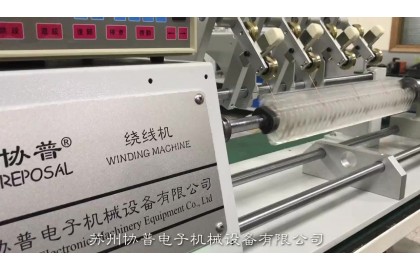

Automatic tape wrapping machine

Suzhou REPOSAL®Electronic Machinery Equipment Co., Ltd. developed a fully automatic iron core coating machine,

Related Post

REPOSAL® releases layer-wound high-voltage package full-automatic interlayer insulation winding machine

REPOSAL® releases layer-wound high-voltage package full-automatic interlayer insulation winding machine

Suzhou Xiepu Electronic Machinery Equipment Co., Ltd. successfully released the SP-D102M7 model of layer-wound high-voltage package automatic interlayer insulation winding machine-this model greatly improves the winding efficiency of layer-wound high-voltage package coils, and the coil is consistent Sex. The REPOSAL® winding machine reduces the winding cost of the layer-wound high-voltage package. In the new model, it has added a compact insulation belt automatic cutting mechanism, and high-quality solutions such as dynamic balance performance after multiple skeletons are wound.

Horseshoe hollow cup motor coil and winding machine

Horseshoe hollow cup motor coil and winding machine

In recent years, China has paid more and more attention to hollow cup motor and automatic winding technology, and has made good progress and breakthroughs in the research and development and manufacturing of winding machine equipment.

One of the key reasons for the impact on the performance of the motor is the rotor coil in the motor, the rotor in the hollow cup motor has no iron core, small inertia, excellent functionality and a wide range of applications. In addition, in the research and development of coil winding equipment, the saddle-shaped coil arrangement is regular, and the utilization efficiency of magnets is high.

Compared with the old traditional motor with an iron core, the energy conversion efficiency is significantly higher than the latter, and the reaction speed will be much faster, and the hollow cup motor has high efficiency, fast response speed and stable performance. Because the hollow cup motor has no lag, additional electromagnetic interference is low, very high motor speed can be achieved, and the speed setting is sensitive at high speed, so it has relatively stable and stable performance. In addition, the energy density of the hollow cup motor is much greater than that of other motors, and the weight will be much less than that of an iron core motor with the same power.

Now according to the forming method of the coil, in the hollow cup motor coil, its production technology can be roughly divided into two process routes: winding production technology and one molding production technology.

Compared with the two methods, the first winding production technology is more complex, and the efficiency of winding the coil is relatively low. In order to improve the winding efficiency of coil production, the winding machine can be added to the production process of one molding. According to the hollow cup coil shape and winding method, the common hollow cup winding method can be divided into three kinds of parallel straight winding, saddle winding and oblique winding. The first parallel straight winding is generally used for hollow cup motor winding with relatively few turns. The last two are the two coil winding processes commonly used by the relatively advanced hollow cup motor manufacturers abroad.

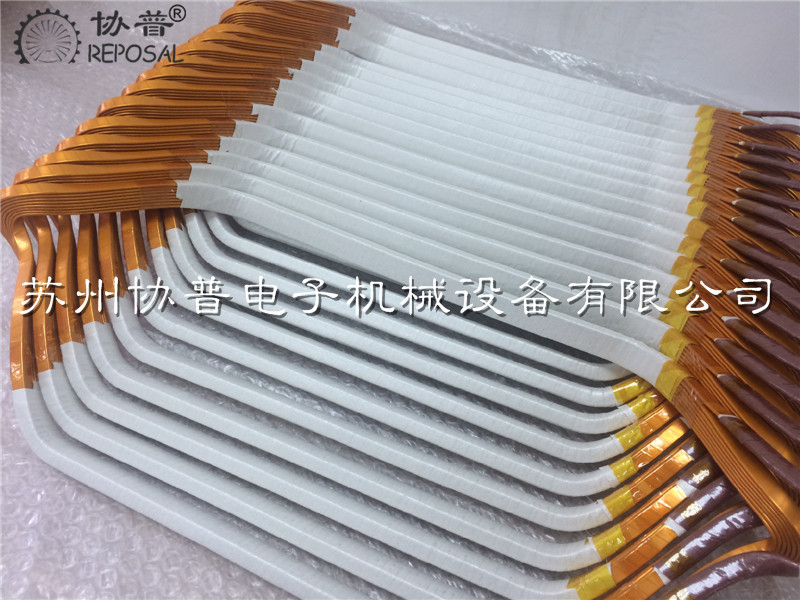

REPOSAL's successfully developed precision flexible Roche coil winding machine

Precision Flexible Roche Coil Winding Machine is a special equipment for winding precision flexible Roche coils. With the actual project as the background, Xiepu successfully developed a precision flexible Rogowski coil winding machine by decomposing the flexible Rogowski coil winding process.

The precision flexible Roche coil winding machine does not belong to the ranks of general numerical control equipment, but a special non-standard equipment. For this type of equipment, it is mainly reflected in a special purpose. Since the special purpose means that the market demand is not large, it is indispensable. For equipment manufacturers, the development of such special equipment is not favored, and cost control is very difficult.

In addition, the current domestic manufacturers of flexible Roche coils have limited demand for equipment. At the same time, if you want to control the pitch accuracy and alignment, the equipment research and development costs are relatively high, and the market risk is large. At the same time, for equipment users, their corresponding The supporting equipment and instruments are a large investment.

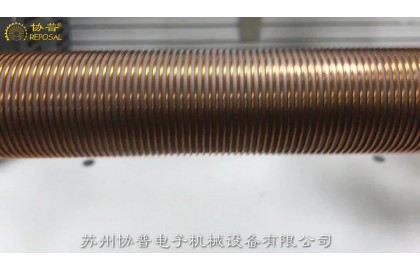

REPOSAL successfully developed string winding machine

REPOSAL takes the string winding machine as the research object and adopts the modal analysis method. Firstly, the vibration principle and the movement principle of the winding mechanism of the small string winding machine are discussed in theory. Based on the principle analysis, the vibration analysis of the ADAMS model of the small copper wire winding mechanism to study the vibration damping characteristics between the roller shaft and the frame is carried out respectively, and the wire winding mechanism of the string winding machine is made using ANSYS software. Modal analysis was carried out for normal operation. Through analysis, the vibration characteristics of the winding mechanism of the string winding machine under normal working conditions are obtained respectively to optimize the vibration damping measures of the winding mechanism. At the same time, the mechanical characteristics of the thin wire and CNC under the normal working state of the CNC winding mechanism are analyzed. , Optimizing the feasibility of applying the CNC cable winding mechanism to the string winding machine cable winding mechanism.

REPOSAL Winding Machine® Released Tandem flat-wound winding machine

REPOSAL Winding Machine® Released Tandem flat-wound winding machine

REPOSAL® successfully developed linear motor winding machine

The linear motor winding machine developed by Suzhou REPOSAL® Electronic Machinery Equipment Co., Ltd. successfully completed the test, achieved success, and was successfully put into production.

At present, in traditional linear motor winding machines, the stator coils are individually wound and then assembled on the linear motor core in sequence, and then welded between the stator coils. The process is many, the efficiency is low, and there are many process nodes such as manual intervention assembly and welding. At the same time, the quality is unstable, which affects the cost of the traditional linear motor for a long time. The successful research and development of the linear motor winding machine of this specification will further reduce the cost of the linear motor and improve its quality.

Based on the process of this linear motor winding machine, the company has reached a further research and development agreement with long-term cooperative customers to replace the traditional circular stator coil inner winding process. There are two reasons for its cost to apply the company's linear motor After the winding machine, there is a very large drop space. One is because the existing inner winding stator coil has a toroidal core, so the utilization rate of the material is low. The current plan is to design it as an unfolded type. The utilization rate will be at least doubled. The second is the inner winding of the stator coil. Due to technological limitations, its winding method can only be wound by a single wire. The REPOSAL'slinear motor winding machine winds three windings at the same time, and its processing efficiency is tripled. The combination of the two aspects will greatly reduce the cost of the inner winding stator coil.

At the same time, Suzhou REPOSAL® Electronic Machinery Equipment Co., Ltd. will further optimize the design and production process, and strive to continue to reduce the cost of the whole machine under the existing cost advantage, so that the production company can save materials and improve efficiency, while also greatly reducing The purchase and use cost of the winding machine-make REPOSAL's partners more competitive.

Winding machine is used for winding multi-strand wire rope

The customer requires winding multi-strand steel wire rope with a total diameter of 3.5mm, multi-layer winding, which requires stability and speed.

Process requirements of traction motor winding machine

Traction motors are mainly used for railway mainline electric locomotives, industrial and mining electric locomotives, electric drive diesel locomotives and various electric vehicles (such as battery cars, urban trams, subway electric vehicles).

The constraints of the coil during the winding process of the winding machine mainly come from two aspects: design requirements and craftsmanship. The specific manifestations are:

The structural design of coils and windings must not only meet the requirements of electrical performance and temperature rise limit, but also the applicability of existing winding machines, the economical and reasonable use of electromagnetic wires and insulating materials, simple structure and convenient manufacturing, that is, it should have Good manufacturability. In order to achieve better manufacturability and reliability, there are some control points that must be considered in the early stage. For this type of problem, REPOSAL®winding machine shares some content with you.

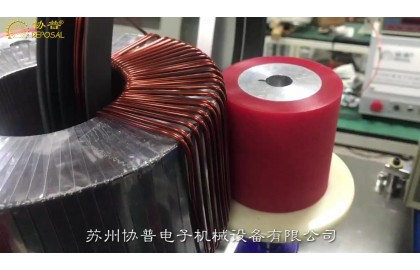

Toroidal transformer winding machine

Toroidal transformer winding machine

The company has the advantages of R&D and production of electronic transformers and transformers in the whole factory equipment. Different from many assembly manufacturers in the industry, we have accumulated many years of experience in R&D and production in the winding machine industry and developed a new generation of toroidal coil series winding The equipment is widely used in the manufacturing industries of toroidal transformers, transformers, voltage regulators, inductance coils, etc., and has been well received by the industry; Suzhou REPOSL will continue to understand user needs and strengthen technical research and development and after-sales service levels, and provide customers with more professional and high-quality products and service.

Technical features of our toroidal transformer winding machine:

Using CNC digital intelligent program controller, stable work, simple operation, with a number of industry-first advanced and practical functions.

The core components such as the thread storage ring and the thread belt are made of high-quality steel through multiple processes, which are durable and not deformed.

It adopts advanced control circuit and has fault alarm function. The function switches are all controlled by two lines, which is easy to maintain and replace.

The operating speed is set separately in the storage and winding state, which can automatically realize the fast storage and low-speed winding operation. The automatic operation function can also be used in the taping machine mode. The operation is simple and the use efficiency is high.

When processing multi-winding products, multiple storage and multiple winding procedures can be preset, which is suitable for products with multiple windings but different wire diameters/numbers of turns, or products with insufficient wire storage in a single time, eliminating repeated installation Clamping and manual operation improve production efficiency.

Multiple sets of wire density can be preset, and the device can automatically change the preset wire density when winding. When processing multi-winding products, each winding with different turns can be evenly arranged at a preset angle.

Double frequency conversion proportional drive, automatic operation or pedal speed regulation can be selected.

The speed can be adjusted steplessly, and the appropriate winding speed can be set according to the process requirements of different products.

Features:

The gear winding machine has the characteristics of large winding torque, high opening size of the gear ring roof ring, a large amount of wire storage and a large range of suitable winding diameters. It is the most versatile

Winding model; suitable for products with thick winding diameters, neat wiring requirements and multiple parallel windings, such as small toroidal transformer secondary windings, high-power 驽

Technical features of our toroidal transformer winding machine:

Using CNC digital intelligent program controller, stable work, simple operation, with a number of industry-first advanced and practical functions.

The core components such as the thread storage ring and the thread belt are made of high-quality steel through multiple processes, which are durable and not deformed.

It adopts advanced control circuit and has fault alarm function. The function switches are all controlled by two lines, which is easy to maintain and replace.

The operating speed is set separately in the storage and winding state, which can automatically realize the fast storage and low-speed winding operation. The automatic operation function can also be used in the taping machine mode. The operation is simple and the use efficiency is high.

When processing multi-winding products, multiple storage and multiple winding procedures can be preset, which is suitable for products with multiple windings but different wire diameters/numbers of turns, or products with insufficient wire storage in a single time, eliminating repeated installation Clamping and manual operation improve production efficiency.

Multiple sets of wire density can be preset, and the device can automatically change the preset wire density when winding. When processing multi-winding products, each winding with different turns can be evenly arranged at a preset angle.

Double frequency conversion proportional drive, automatic operation or pedal speed regulation can be selected.

The speed can be adjusted steplessly, and the appropriate winding speed can be set according to the process requirements of different products.

Features:

The gear winding machine has the characteristics of large winding torque, high opening size of the gear ring roof ring, a large amount of wire storage and a large range of suitable winding diameters. It is the most versatile

Winding model; suitable for products with thick winding diameters, neat wiring requirements and multiple parallel windings, such as small toroidal transformer secondary windings, high-power 驽

Outer diameter: 193mm

Inner diameter: 95mm

Height: 90mm

Enameled wire diameter: 2.5mmX370

Introduction of winding method of electric heating tube

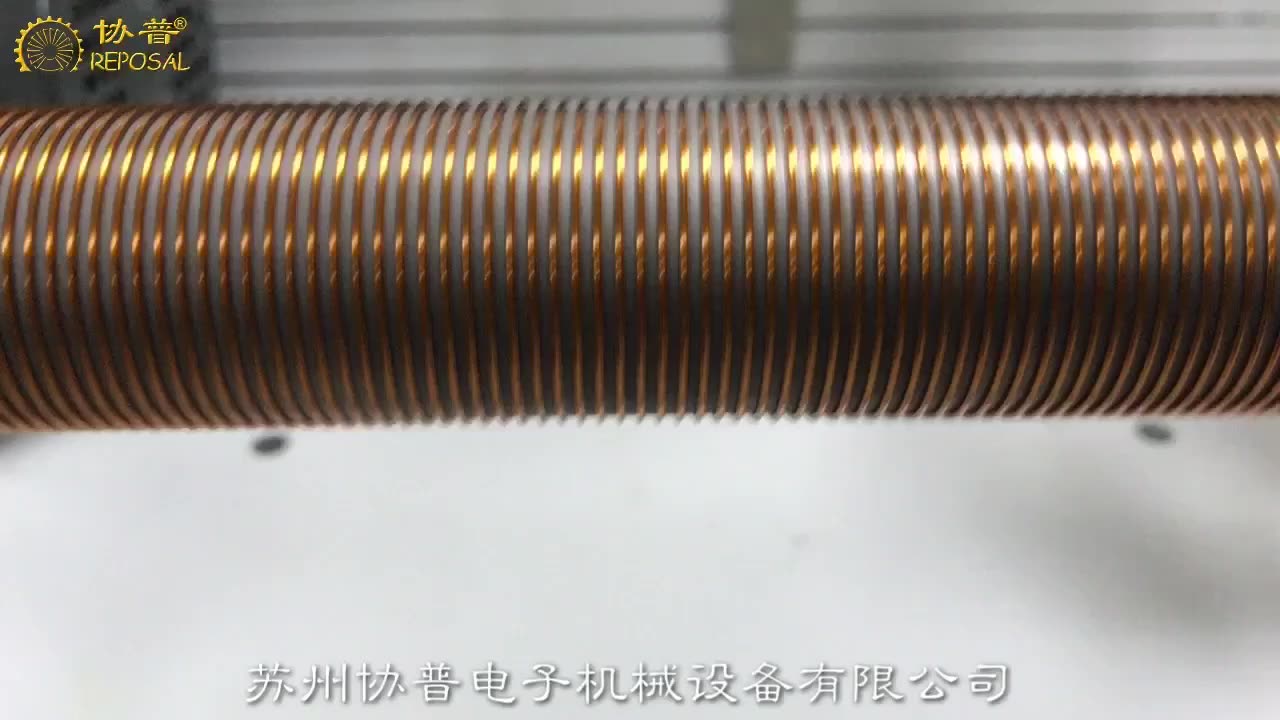

This type of winding machine of Xiepu has a stroke of 1.5 meters, adopts pneumatic quick assembly and quick disassembly, convenient operation, mature and stable structure, easy maintenance, easy operation of the system, complete functions, and strong expandability.

At present, according to customer requirements, a heating coil with a stroke of up to 1.5 meters is wound on this machine. Because the equipment is structured in place, the winding has a satisfactory effect. The customer currently plans to add mica tape winding function on this basis.

Clamp Ammeter Coil Winding Machine|Clamp Meter Coil Winding Machine|Semicircle Transformer Winding Machine

Clamp Ammeter Coil Winding Machine|Clamp Meter Coil Winding Machine|Semicircle Transformer Winding Machine

The semi-circular coil winding machine developed by Suzhou Xiepu Electronic Mechanical Equipment Co., Ltd. is suitable for the winding of semi-circular skeleton, iron core and magnetic core coil. Its running operation, high speed, safety cover is convenient and practical. Fast and repeatable positioning accuracy. Applicable products are: semi-circular transformer coil, semi-circular heating wire coil, clamp meter coil, etc.