Instructions for use of standard winding machine tensioner

Instructions for use of standard winding machine tensioner

Related Post

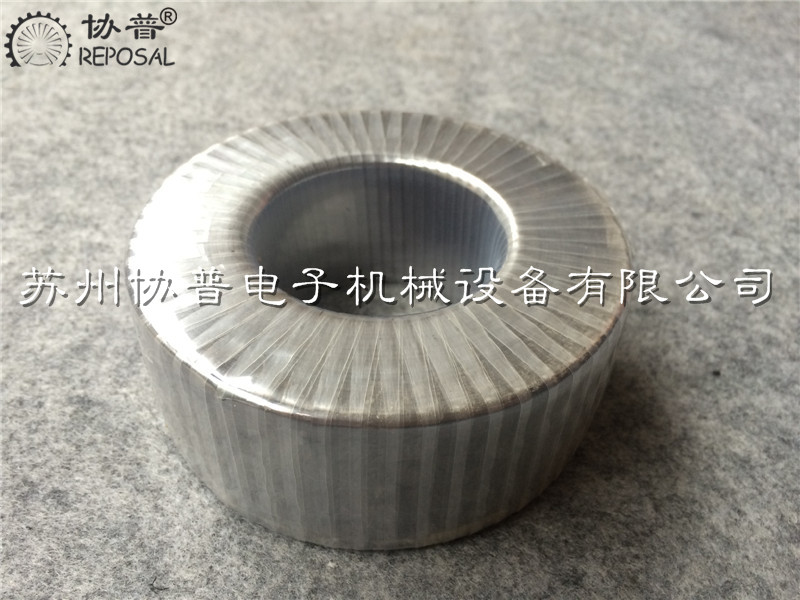

REPOSAL® Toroidal transformer Taping Machine Instructions

Toroidal transformer Taping Machine Instructions

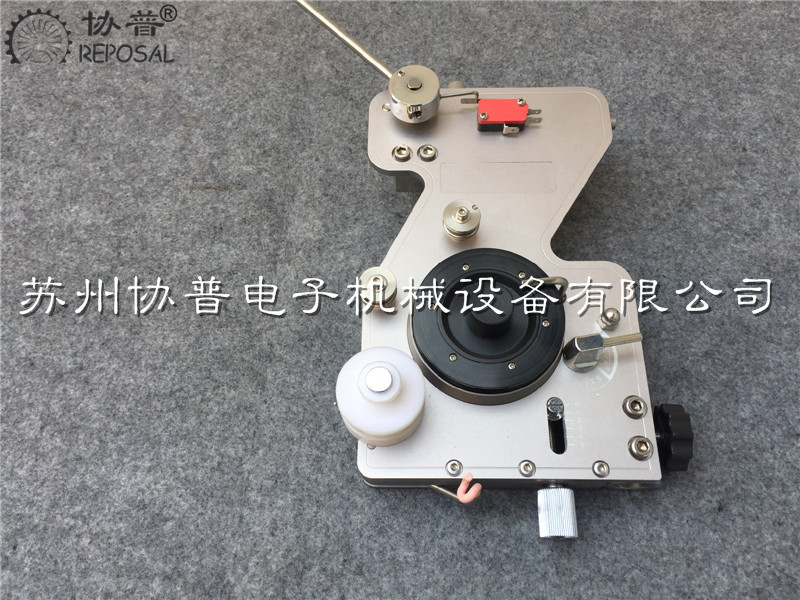

Mechanical Tensioner Guide

Let's now look at the tensioner, a threading process. First, the enameled wire passes through the ceramic ring at the bottom of the tensioner, and then passes through the wool felt above it. The clamping degree of the wool felt can be adjusted by passing the knob on the other side of the tensioner.

Then go through the anti-jumper, and then go over the damping wheel on the tensioner once again, then pass through an anti-jumper again, and then pass through the guide wheel on the fishing rod, this is the threading process.

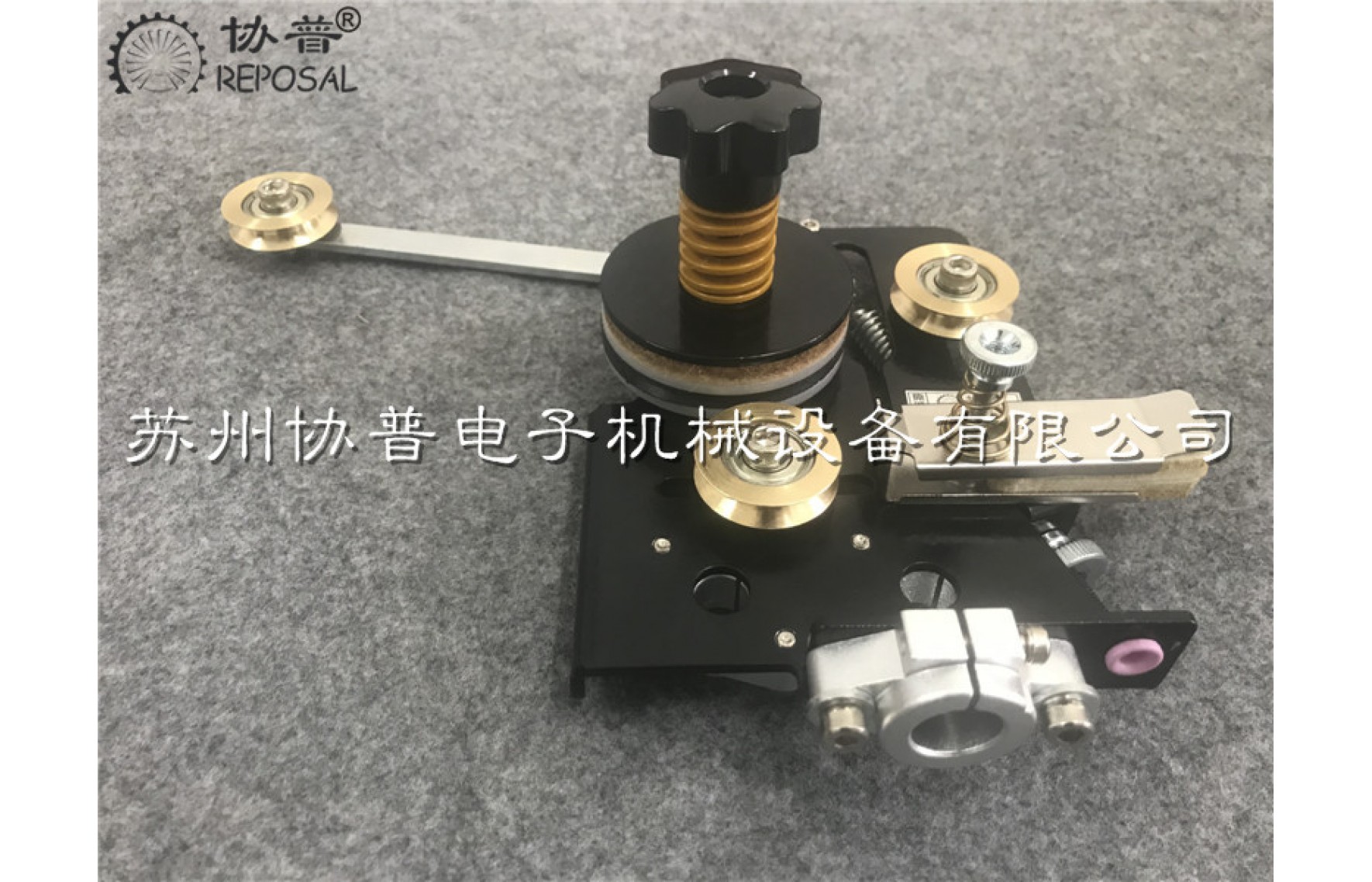

Then how do we adjust to a more appropriate tension?

Let's take a look at the first one now. This handle is a tension switch. When the tension switch hits the top, the damping wheel doesn't work. When it is turned, it becomes very light. When the tension switch hits the bottom, the tensioner starts to work.

If we want to increase the tension, we adjust the knob under the bottom of the tensioner, there is a scale in this position. Through this, adjust the damping size of the damping wheel on the tensioner.

Then the handle at this position is used to adjust the back tension, which is the force of the fishing rod to bounce back. The general principle of our adjustment is that during the winding process, the fishing rod will not become weak under the interaction of the damping wheel. Sagging down, it will not be too strong and only a good swing requires a relatively large swing range, so that it can buffer and at the same time play a role in tensioning the enameled wire.

Instructions for use of magnetic damping tensioner for winding machine

Instructions for use of magnetic damping tensioner for winding machine