Side-slip toroidal coil winding machine-wire passing method

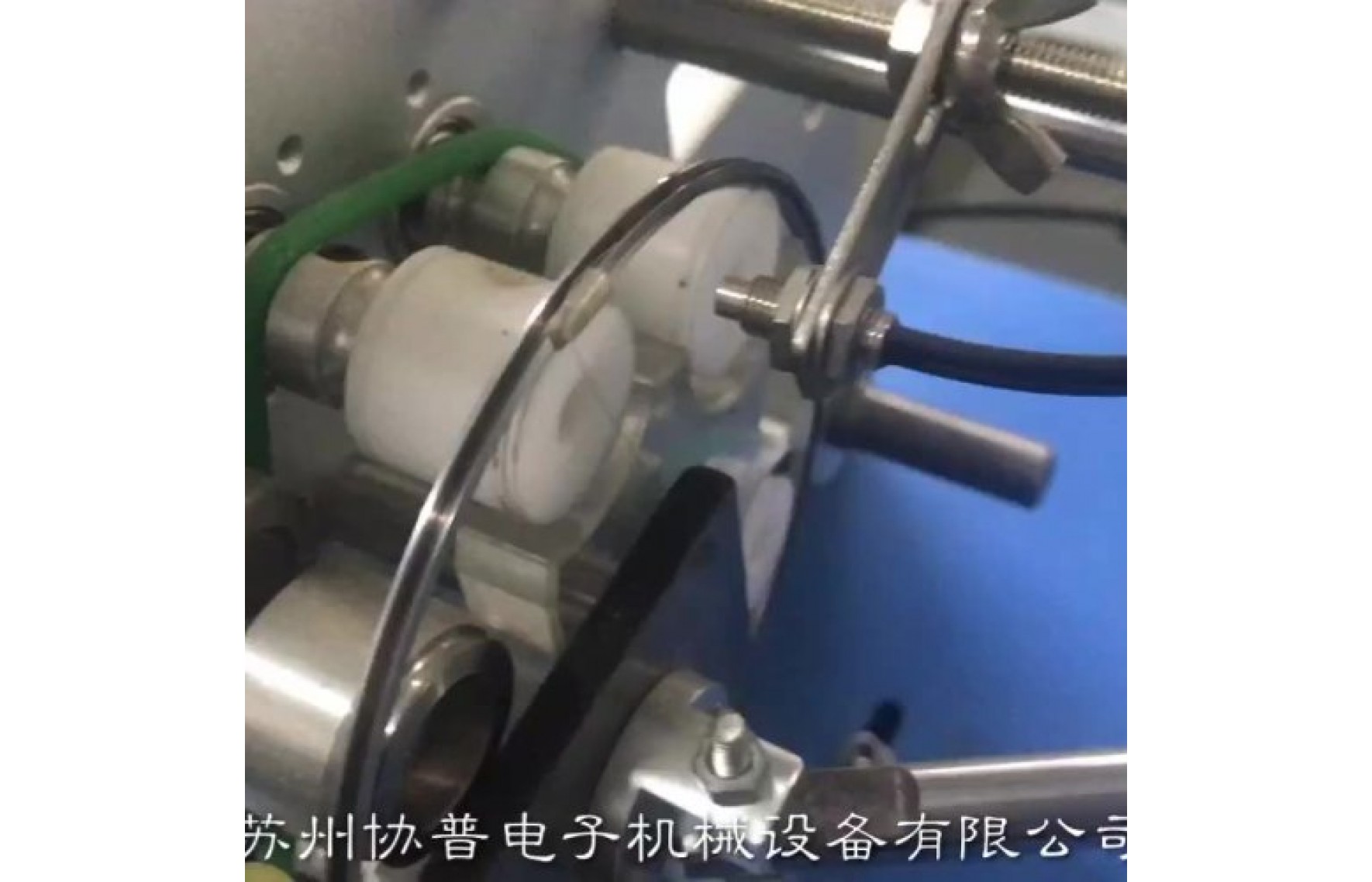

Wire passing method of side-slip loop coil winding machine:

For the side-slip toroidal coil winding machine, the setting method of the controller is basically the same as the belt-type toroidal coil winding machine, the difference is that the winding direction and the storage direction, when a person stands on the right side of the winding machine, The storage direction of the belt loop coil winding machine is counterclockwise, while the storage direction of the side slip loop coil winding machine is clockwise, and when winding, the belt loop coil winding machine and the belt loop The direction of the coil winding machine is the same, which is counterclockwise.

Generally, in order to facilitate the observation of the winding situation, we can press the "Start" button twice in the winding phase. At this time, when we turn the rotating handle on the left side of the ring coil winding machine stand by hand, we can easily and clearly Observe the winding process of the enameled wire.