REPOSAL® Winding Machine successfully overcomes the difficulty in the winding process of closed coils of fixed-length titanium plates with loops.

REPOSAL® Winding Machine successfully overcomes the difficulty in the winding process of closed coils of fixed-length titanium plates with loops.

The titanium plate with loop is an implantable consumable and basic surgical instrument approved by the National Medical Products Administration (NMPA). Its structure seems simple, but its processing technology is difficult. For a long time, it has been monopolized by foreign brands.

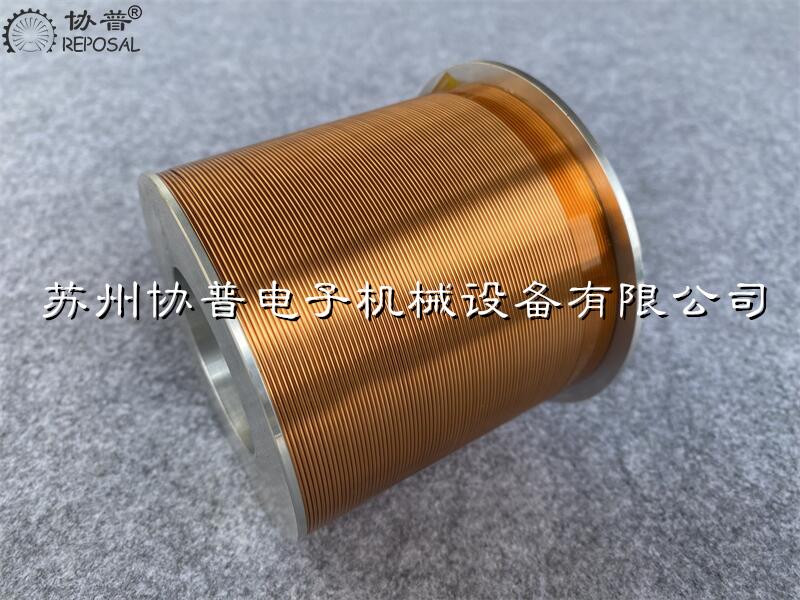

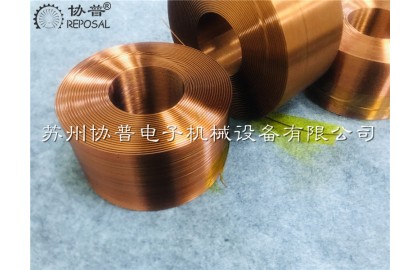

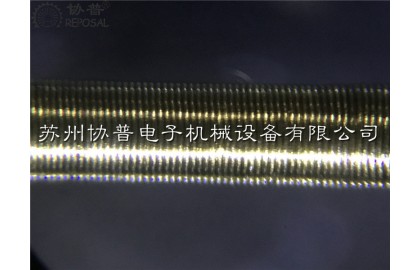

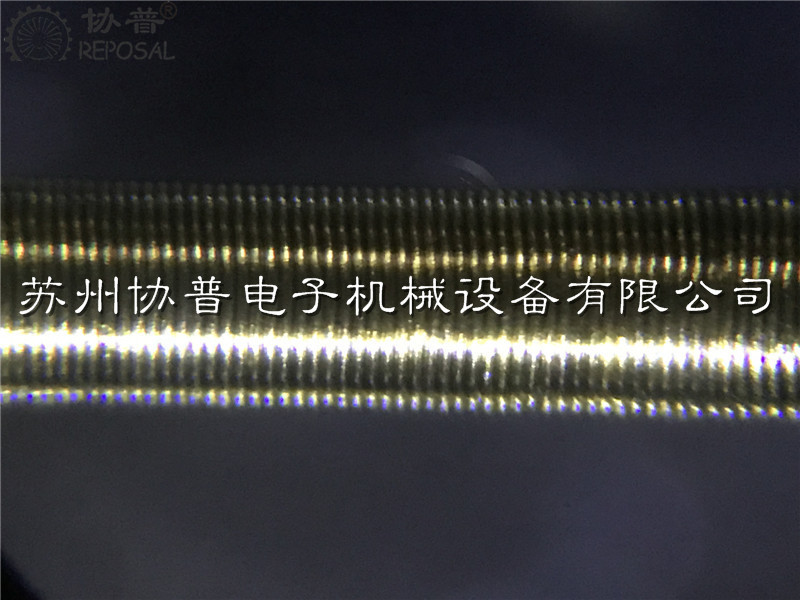

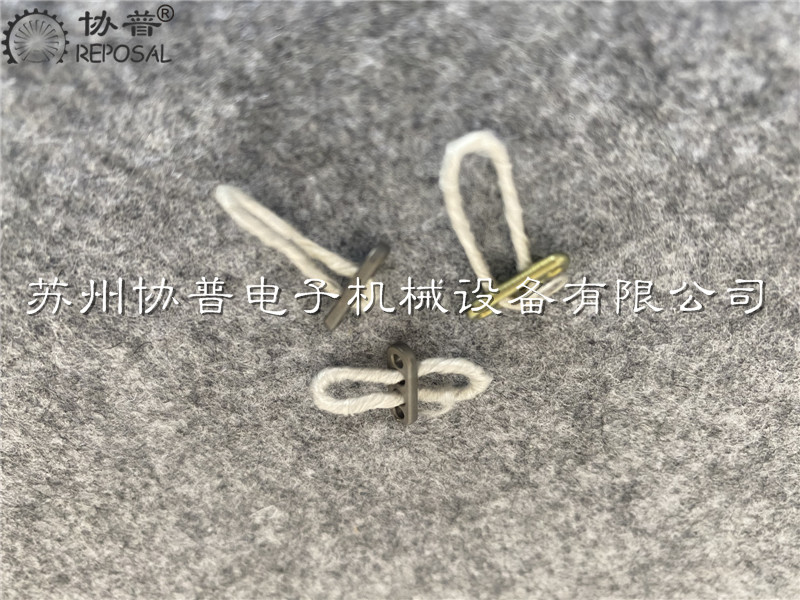

These tiny looped titanium plates are shown here, small metal structures approximately 12mm long, 4mm wide and 1.5mm thick, and have a row of four circular holes through them, two of which are for The main body pulls the suture through, and the other two upper holes are used for the passage of another group of seam lines. The structure is small in size, and it is necessary to form a closed connecting loop through the structural member, and the closed connecting loop is formed by twisting the yarn fibers of the loose structure. A closed high-strength braided coil is passed through the middle, which seems simple, but its core technology is reflected in the Loop, that is, a high-strength coil, which is woven evenly, tightly, non-woven, and without joints.

This kind of titanium plate with loops is divided into two types, fixed-length type and adjustable type, especially the fixed-length type, whose length ranges from 15mm to 60mm. It is necessary to wind this closed loop in the middle of a titanium plate with such a small volume. Coils, and because the number of colonies cannot exceed the standard, cannot be wound by hand, but must be wound by equipment, which is extremely difficult to process.

Therefore, the import price of these seemingly simple titanium plates with loops has remained high. In the past, the patents and production technologies for these materials were mainly held by European companies. Today, REPOSAL® Winding Machine, as an automatic equipment manufacturer specializing in special winding technology, is the first to fill the gap in this process technology in my country.

The looped titanium plate winding process developed by REPOSAL® winding machine can wind the fixed-length looped titanium plate with a length between 15mm-60mm. Moreover, the key performance indicators of the finished product have reached or even exceeded the level of imported products of the same type. REPOSAL® winding machine is expected to assist our customers in realizing the import substitution of the same type of titanium plate with loops - making our customers more competitive!