REPOSAL's successfully developed precision flexible Roche coil winding machine

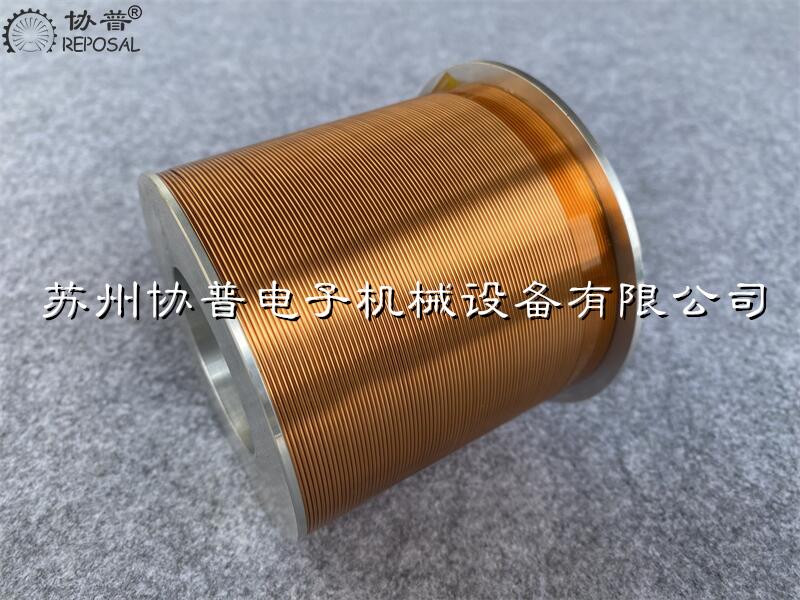

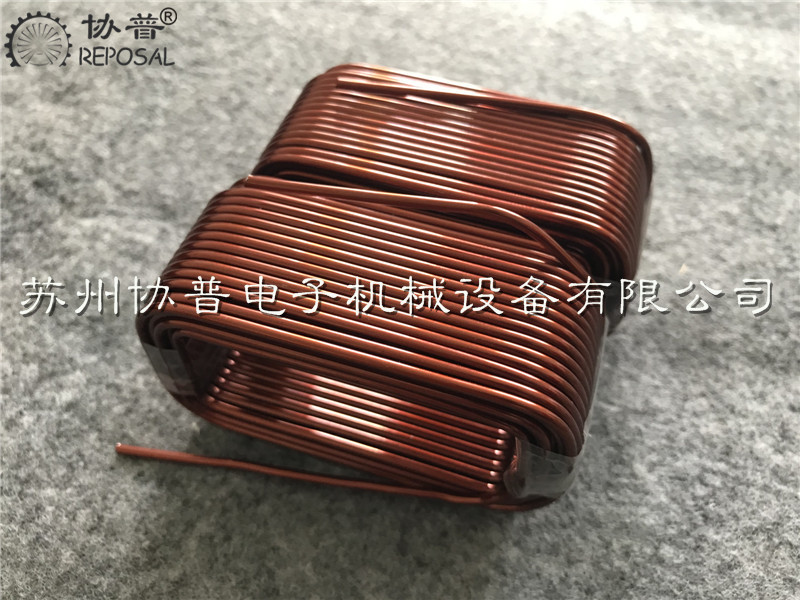

Precision Flexible Roche Coil Winding Machine is a special equipment for winding precision flexible Roche coils. With the actual project as the background, Xiepu successfully developed a precision flexible Rogowski coil winding machine by decomposing the flexible Rogowski coil winding process.

The precision flexible Roche coil winding machine does not belong to the ranks of general numerical control equipment, but a special non-standard equipment. For this type of equipment, it is mainly reflected in a special purpose. Since the special purpose means that the market demand is not large, it is indispensable. For equipment manufacturers, the development of such special equipment is not favored, and cost control is very difficult.

In addition, the current domestic manufacturers of flexible Roche coils have limited demand for equipment. At the same time, if you want to control the pitch accuracy and alignment, the equipment research and development costs are relatively high, and the market risk is large. At the same time, for equipment users, their corresponding The supporting equipment and instruments are a large investment.

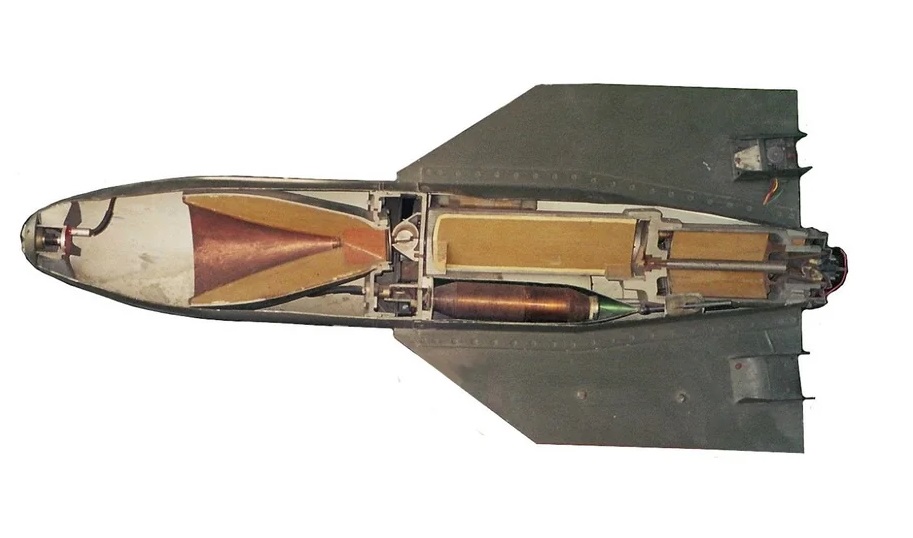

The precise and neat arrangement of the pitch of the flexible Rogowski coil is critical to its performance. High-precision flexible Roche coil winding equipment, several domestic flexible Roche coil manufacturers have been relying on imported equipment for several years, but the general process requirements of this special equipment are relatively complicated, and foreign countries have been restricting exports of high-tech products to my country.

At present, domestic winding machine manufacturers do not pay attention to technology accumulation and innovation for a long time.Although there are corresponding machines, the control accuracy, tension control system, spool control mechanism, etc., are all because of the lack of control over the process conditions. It is full and very simple. The product that is wound out has only its shape and no precision.

After a detailed analysis of the mechanical mechanism and winding process of the equipment, Xiepu winding machine proposes the technical difficulties of winding the flexible Rogowski coil, and proposes corresponding solutions to the technical difficulties, and at the same time explains the solution control principles. Finally, we successfully developed a precision flexible Roche coil winding machine.

The flexible and flexible Roche coils put forward more stringent requirements on the winding machine, which are mainly reflected in the following aspects, one of which is that the mechanical structure is reasonable, and the other is that the corresponding mechanical tolerances of the high-precision equipment are better matched, and the third is to choose the corresponding Structural materials, some structures need special processing to meet the requirements of use. This can ensure that the vibration caused by the mechanical transmission of the control system during operation can be small, that is, stable and fast.

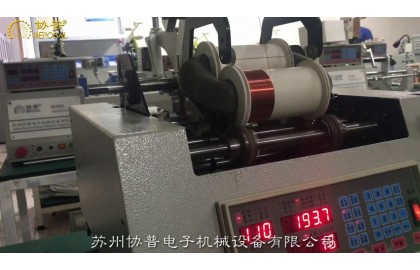

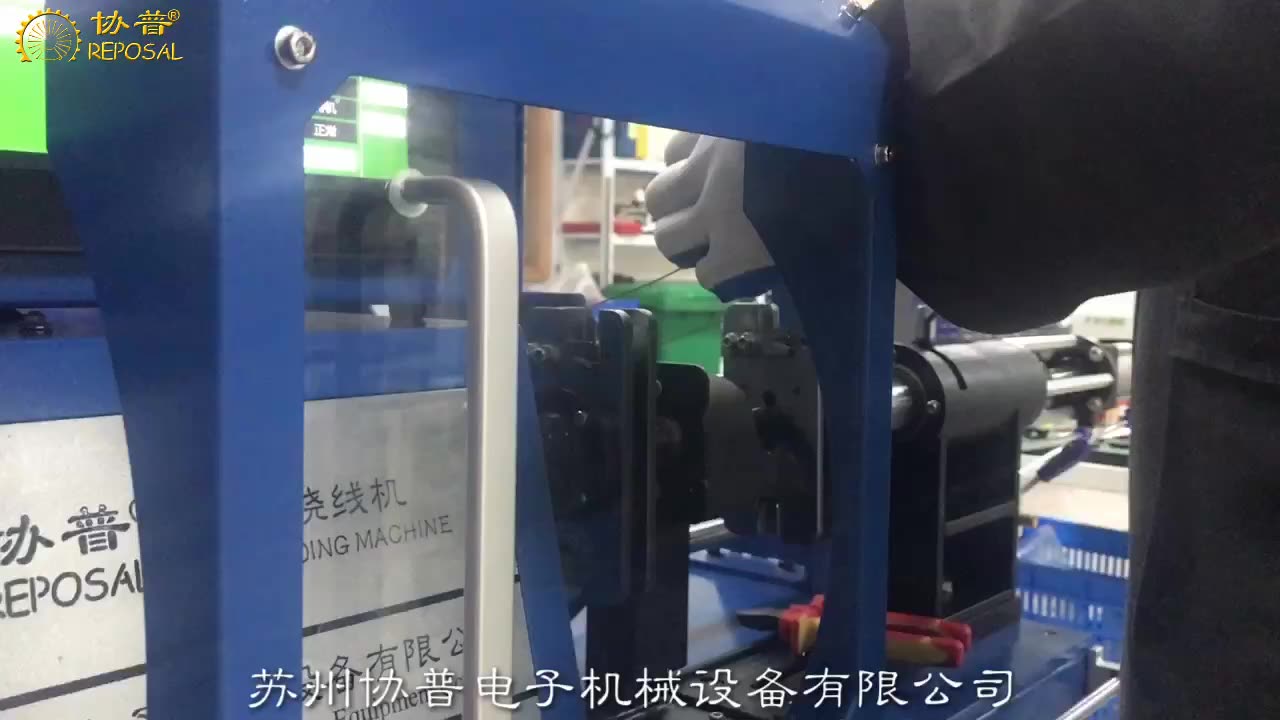

Before introducing the mechanical mechanism, the winding process of a mechanical structure for winding a flexible Rogowski coil is roughly introduced. This mechanical structure is a mechanical mechanism that clamps at both ends and moves the wire through the screw to move the horizontal mechanism in the middle. When winding, it is required to have a good clamping of the core rod, and the core rod and the clamping mechanism are not allowed to slide relative to each other. Then, the enameled wire should be wound around the core rod and fixed in advance. The two fixed shaft motors are Fast rotation at the same speed and opposite direction drives the clamped core rod to rotate quickly. The winding mechanism of the winding machine moves in the horizontal direction at a corresponding speed to passively wind the enameled wire on the core rod, thereby completing the single spiral structure of Roche coil Winding.

The fixed base of the winding machine is generally fixed to the mechanical base through a positioning pin. The tailstock is generally a mechanism that can move horizontally. It is installed on a parallel rail to help achieve the clamping of core rods of different lengths. Equipped with a set of clamping mechanism to realize clamping and locking of the core rod. And start and stop synchronously under the drive of the winding motor, and the rotation speed is constant. The difference is that the two directions of rotation are opposite, because only in this way can the clamped mandrel be kept in one direction of rotation. At the same time, under the drive of the motor, the ball screw converts the circular motion of the motor into the linear motion of the horizontal worktable, thereby driving the winding mechanism of the winding machine installed on the horizontal motion worktable to ensure the enameled wire during the horizontal movement. At a certain angle, under the rotation of the core rod of the flexible Rogowski coil, the passive constant tension cable is arranged to complete the winding process.

In order to ensure the mechanical accuracy of the system, it should be emphasized here that first of all, the coaxiality of the fixed base of the winding machine and the clamping mechanism, and the tailstock and the clamping mechanism of the tailstock must be ensured. The coaxiality of the fixed seat. Under ideal circumstances, the axes of the two should coincide. The clamping mechanism of the winding machine does not allow relative slippage during winding when clamping the core rod. At the same time, the clamping mechanism must not damage the core rod due to the excessive clamping force of the flexible Roche coil core rod.

For the ball screw, it is required to use a hard connection with the coupling when the output shaft of the drive motor is connected, so that the twisting error generated by the screw during rotation can be reduced as much as possible, and the movement of the horizontal movement table also requires high precision Supported by the guide rail to ensure smooth horizontal transmission of the screw without large jumps, which requires the parallelism of the winding machine guide rail, the guide rail spacing, and the level of the surface on which the guide rail is installed must be relatively high requirements .

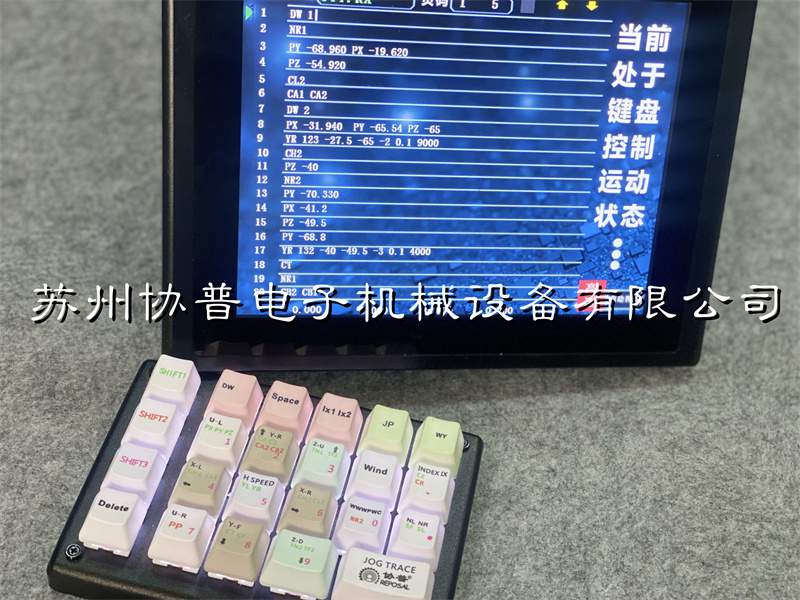

The control principle of the winding machine system is mainly based on the process of spiral winding. On the basis of a certain understanding of the mechanical structure, it points out that some key links in the mechanical structure affect the winding accuracy, so that the control system must be On the basis of ensuring the accuracy of mechanical assembly, we can better control the motion of each axis, and use this as the basic starting point for the construction of the control system.

After introducing the general machinery and winding process, the technical difficulties that need to be solved for the precision flexible Roche coil winding machine are proposed.

The first difficulty is to solve the problem of the synchronous start and stop of the winding machine fixed base and the tailstock motor when the clamping core rod rotates. In addition to ensuring that the winding machine mechanical structure is coaxial, the two are required to rotate synchronously No obvious relative speed is allowed during the process. If a relative motion occurs, the core rod will be damaged in serious cases, which will directly lead to the failure of the winding. However, the pitch of the helix is not up to the standard, that is, the pitch is too bad!

The second difficulty is the speed matching problem of the ball screw to the fixed base motor in the horizontal direction, the linear motion accuracy of the horizontal table, and the speed matching problem corresponding to different winding modes, and the stability of the corresponding speed, namely How to reduce the influence of speed disturbance on the winding pitch. Because the mismatch of speed and the inaccuracy of motion accuracy directly lead to the winding spiral coil can not meet the process error requirements.

Regarding the accuracy of the winding movement, it is necessary to mention the various disadvantages brought by the mechanical coordination error of the ball screw itself, the positive error during the winding movement, and the backlash. Therefore, it is important to consider the forward compensation technology of the lead screw and the horizontal motion table. There is also the absolute zero positioning technology. Provide a compensation reference for error compensation.

Difficult point three, the constant tension of the cable during the winding process, because the instability of the cable tension will directly affect the consistency of the winding product. As a result, the product cannot be used. On the one hand, the design of the mechanical structure needs to ensure that no large disturbances occur during the cable routing process, that is, to ensure the smoothness of the cable routing process through clever mechanical design.

Taking this as a starting point, Xiepu winding machine builds a special winding control system based on position loop control, and makes optimal adjustments on the mechanical structure with respect to the above clamping accuracy, arrangement stroke accuracy, winding tension control, and finally successfully developed precision Flexible Roche coil winding machine.