REPOSAL successfully developed string winding machine

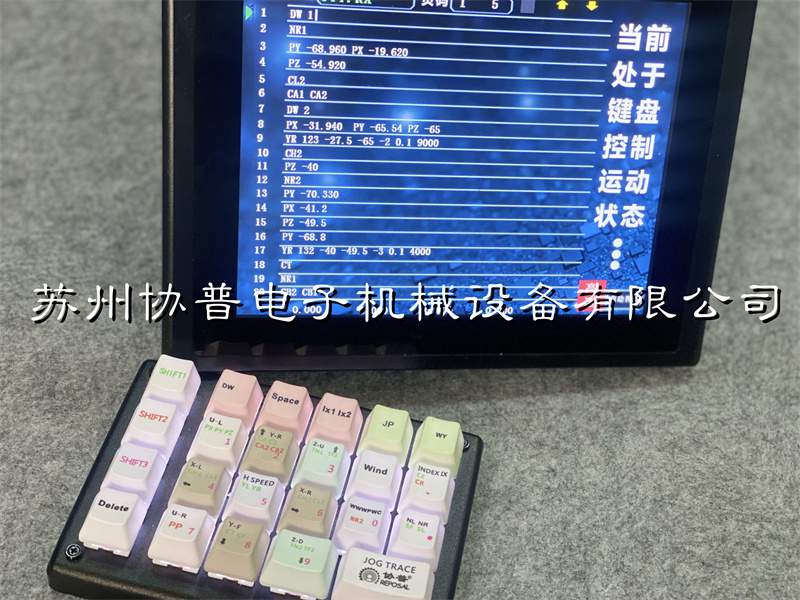

REPOSAL takes the string winding machine as the research object and adopts the modal analysis method. Firstly, the vibration principle and the movement principle of the winding mechanism of the small string winding machine are discussed in theory. Based on the principle analysis, the vibration analysis of the ADAMS model of the small copper wire winding mechanism to study the vibration damping characteristics between the roller shaft and the frame is carried out respectively, and the wire winding mechanism of the string winding machine is made using ANSYS software. Modal analysis was carried out for normal operation. Through analysis, the vibration characteristics of the winding mechanism of the string winding machine under normal working conditions are obtained respectively to optimize the vibration damping measures of the winding mechanism. At the same time, the mechanical characteristics of the thin wire and CNC under the normal working state of the CNC winding mechanism are analyzed. , Optimizing the feasibility of applying the CNC cable winding mechanism to the string winding machine cable winding mechanism.

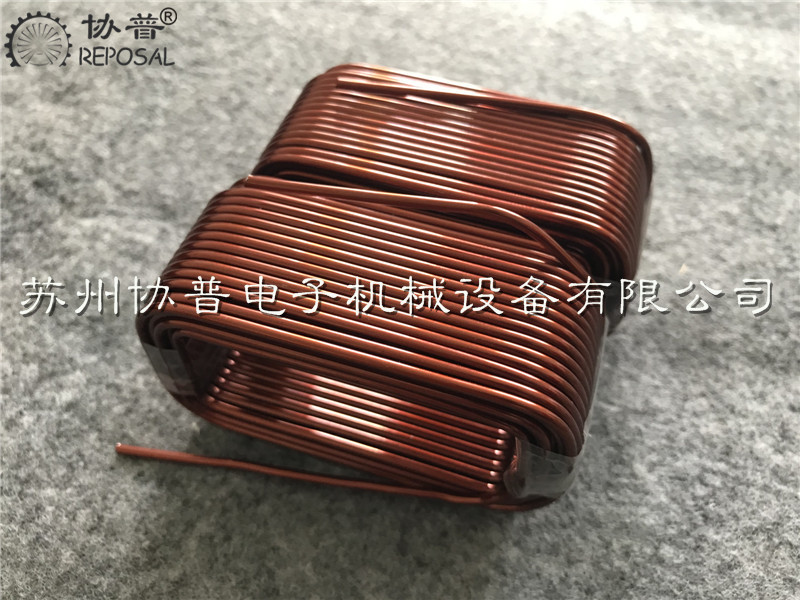

Based on the vibration analysis of the winding mechanism of the string winding machine and the mechanical analysis of the winding mechanism, the roller shaft and the frame factors that affect the vibration characteristics of the small string winding machine are taken as the research objects. The ADAMS software is used to analyze and improve the small string winding. The influence of the vibration generated by the winding mechanism of the winding machine on the thin copper wire and the working environment, and the factors of the thin copper wire and the CNC wire winding mechanism that affect the arrangement characteristics of the copper wire of the small string winding machine are analyzed using ANSYS software to improve the small The twisting and twisting phenomenon of the copper wire that may appear in the winding mechanism of the string winding machine has an effect on the copper wire coil finally obtained. Finally, the winding mechanism of the string winding machine and the winding mechanism are combined to use the actual operation, and the physical principle of the small string wire winding machine platform is used to actually flatten the various types of filaments to finally test the above principle. The final copper wire coil is obtained.

The conclusions drawn through the discussion in each chapter mainly include the following:

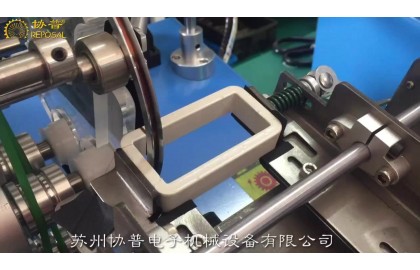

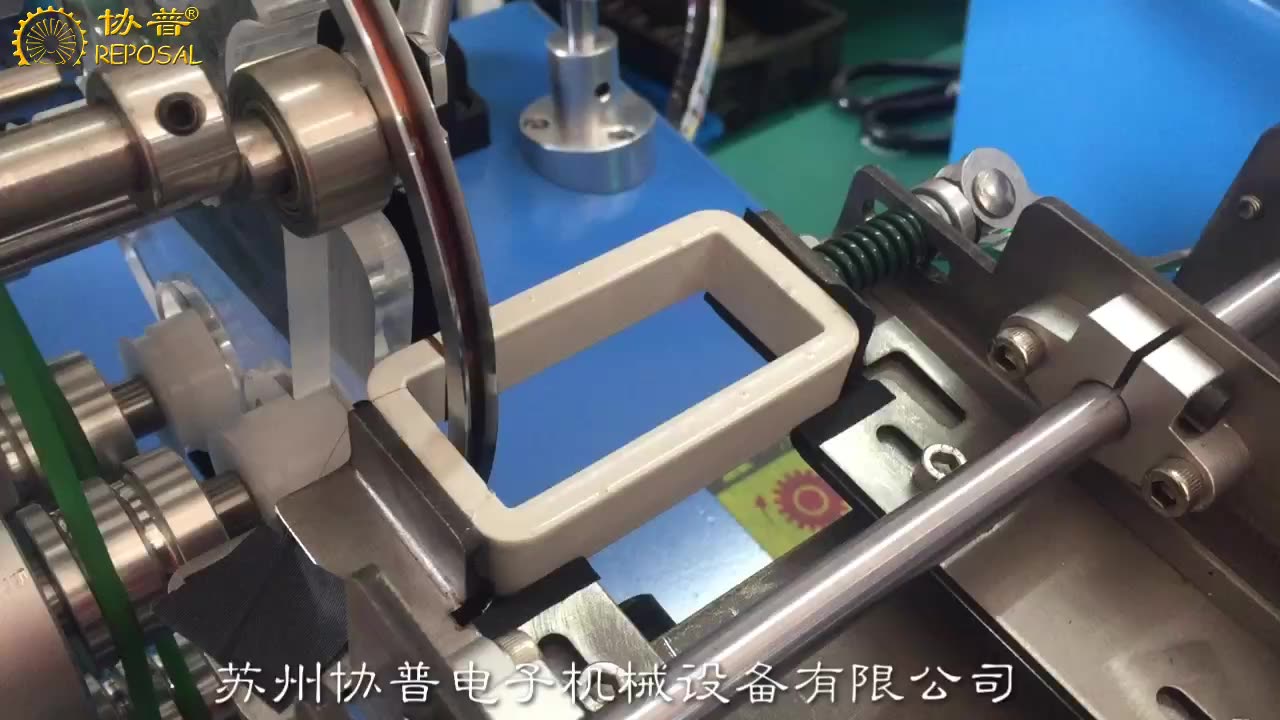

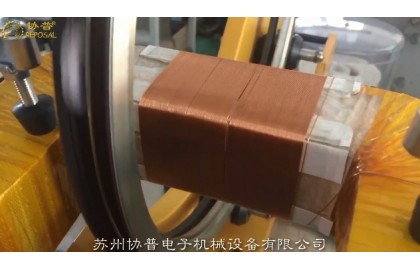

1. After analyzing the overall structure of the string winding machine, the string winding machine is divided into the string winding machine winding mechanism and the string winding machine with the CNC winding mechanism spindle as the boundary. Cable arrangement. The above mechanism decomposition is to facilitate the study of how to obtain high-quality thin copper wire and how to arrange the thin copper wire neatly on the bobbin.

2. The theoretical analysis of the application of vibration mechanics theory to the winding mechanism of the string winding machine through the actual situation that the periodic movement of the roller shaft of the string winding machine during normal operation produces a periodic excitation force for the entire mechanism Increasing the mass m of the frame and reducing the rigidity k of the screw-compressed sliding table can reduce the vibration transmission rate of the system.

3. The ADAMS simulation model is established by applying the ADAMS software based on the actual situation to verify the theoretical analysis of the applied vibration mechanics. The results show that increasing the equivalent mass of the frame m or reducing the rigidity k of the screw-pressed sliding table or at the same time Increasing the equivalent mass m of the frame and reducing the stiffness k of the screw-pressed sliding table can effectively reduce the peak value of the acceleration curve of the vibration response function caused by the excitation force generated by the motion of the roller shaft to reduce the vibration transmission efficiency. The implementation of the above measures can increase the life of the machine, reduce the burden on the worker's body at the same time, and also greatly improve the quality of the flattened filament.

4 The string winding mechanism of the string winding machine is based on the actual characteristics of various types of wire winding devices and the specific characteristics of the thin copper wires that need to be wired. The numerical control cable arrangement with the characteristics of convenient manufacturing and small occupied area is used as the cable arrangement device

5. Using ANSYS software to simulate the movement and force of the thin copper wire passing between the cable spool and the spool according to the actual conditions. The simulation results show that the fine copper wire is arranged on the bobbin after passing through the CNC cable arrangement mechanism. The force applied during the process is mainly the force along the length of the copper wire that can arrange the copper wire neatly on the take-up spool. The second most important force is to cause the copper wire to flip, and the external force acting on the edge of the copper wire is twisted. At the same time, the displacement of the thin copper wire under the action of tension, gravity and other forces in this process is mainly to ensure that the thin copper wire is neatly arranged. Flip, twist, and twist the displacement forward, backward, left, and right. Through software simulation and actual inspection, a satisfactory copper wire coil was finally obtained. The design purpose of the string winding machine is realized.

REPOSAL research analyzes and studies how to improve the quality of the flattened filaments under normal working conditions, and discusses how to arrange fine copper filaments on the spools. practice.

Although due to the existence of practical constraints, the simulation data used in ADAMS and ANSYS software can only select a part from a reasonable interval and cannot apply the data obtained by actual detection of actual sensors with high accuracy, so there will be certain simulation analysis error. However, in the actual development process, we have successfully developed the string winding machine through the accumulation of advanced digital control technology and rich winding technology.