Common accessories of transformer winding machine

Common accessories of transformer winding machine

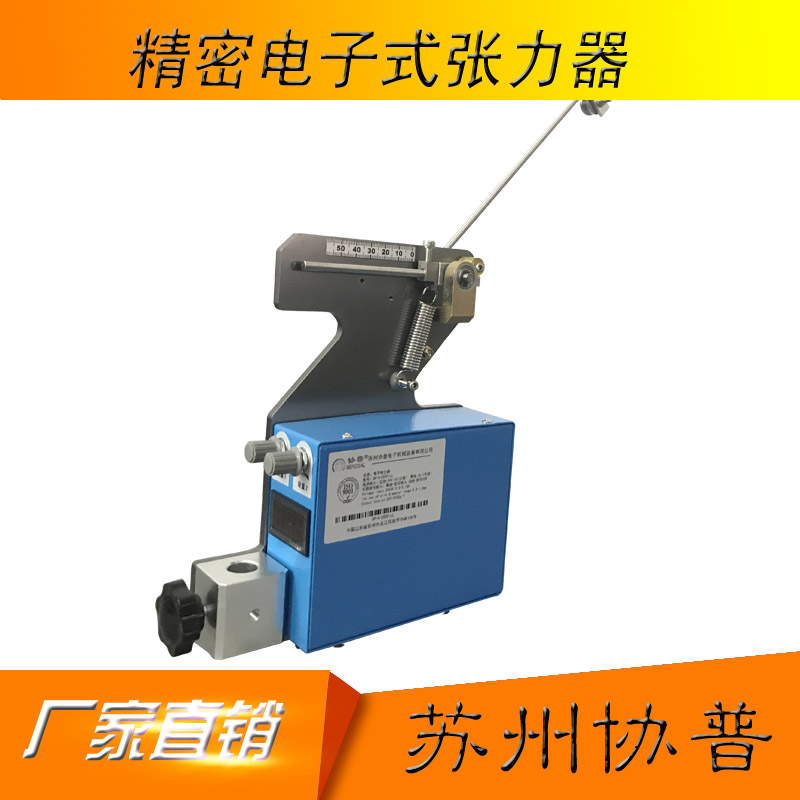

The winding process of the transformer winding machine directly affects the formation of the coil, and the experience is constantly summarized in the actual use of the winding machine and applied to the winding operation. Felt is a friction material used to fix the enameled wire, keep the enameled wire stable during operation, and remove dirt and burrs on the surface of the enameled wire. The clamping force of felt is also one of the sources of enameled wire tension. The tensioner is one of the most important components in the online tension device, and it is also the main component of tension control during the operation of the winding machine. Common tensioners are friction, magnetic damping, and magnetic powder braking.

The winding machine needs many accessories to assist the normal operation of the equipment. Common accessories include spools, molds, clamps, tensioners, thread passing devices (mainly explaining the function and composition of the threading device, the threading device plays a role in conveying, protecting, and reversing during the winding operation, so that the enameled wire can be smoothly removed from (The pay-off bucket is transported to the take-up reel)

Ceramic wheel is the most common component in stringing equipment. It has two types: full ceramic wheels and semi-ceramic wheels. All ceramic wheels are generally used for multi-wire winding occasions. Its structure is relatively simple, consisting of a bearing and a wheel body. The structure of the semi-ceramic wheel is similar to that of the full ceramic wheel, consisting of a bearing, an inner core, and a plastic retaining ring, and is generally used to wind a single enameled wire.

When winding round wires, the winding speed can be increased appropriately, but too slow will affect the wiring of the winding workers. There are two main shapes of transformer round coils: oval and circular. When winding an elliptical coil, pay attention to the angle of the wire, control the beating of the enameled wire at the corner, and pay attention to the uniform movement during the wiring process.