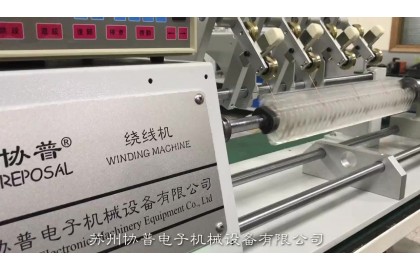

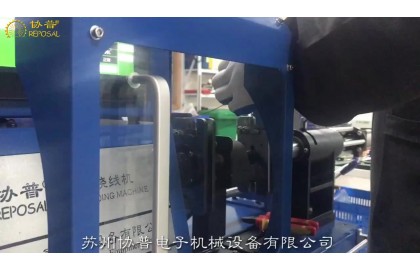

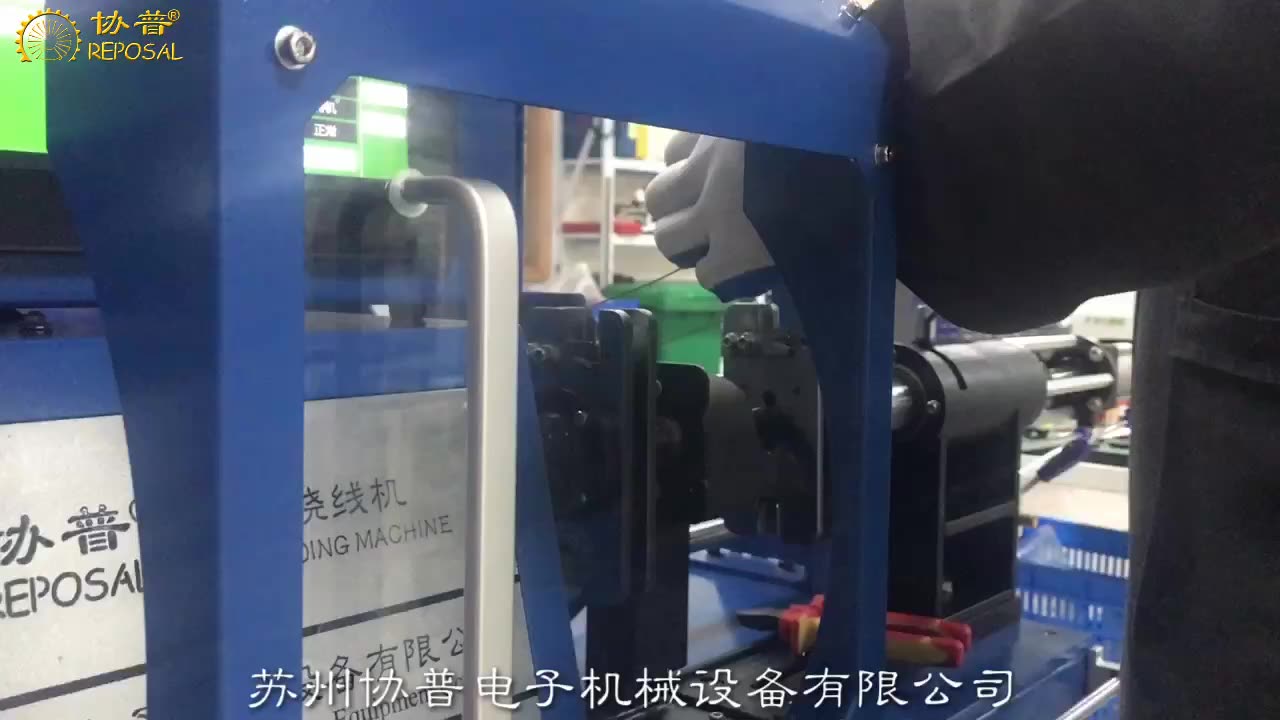

REPOSAL® releases Automatic winding machine

Suzhou REPOSAL® Electronic Machinery Equipment Co., Ltd. released: automatic induction coil winding machine.

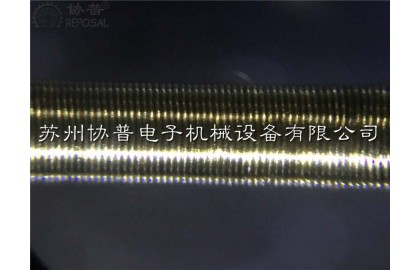

This model is mainly used for the winding of rod-shaped inductors. During the winding process of this winding machine, the rod-shaped inductor realizes unattended full automation. Its winding speed is fast, inductance consistency is good, and debugging Convenient and easy to maintain, it provides a competitive solution for the winding process of rod-shaped inductors for the cooperative customers of REPOSAL®

Related Post

REPOSAL® releases layer-wound high-voltage package full-automatic interlayer insulation winding machine

REPOSAL® releases layer-wound high-voltage package full-automatic interlayer insulation winding machine

Suzhou Xiepu Electronic Machinery Equipment Co., Ltd. successfully released the SP-D102M7 model of layer-wound high-voltage package automatic interlayer insulation winding machine-this model greatly improves the winding efficiency of layer-wound high-voltage package coils, and the coil is consistent Sex. The REPOSAL® winding machine reduces the winding cost of the layer-wound high-voltage package. In the new model, it has added a compact insulation belt automatic cutting mechanism, and high-quality solutions such as dynamic balance performance after multiple skeletons are wound.

Horseshoe hollow cup motor coil and winding machine

Horseshoe hollow cup motor coil and winding machine

In recent years, China has paid more and more attention to hollow cup motor and automatic winding technology, and has made good progress and breakthroughs in the research and development and manufacturing of winding machine equipment.

One of the key reasons for the impact on the performance of the motor is the rotor coil in the motor, the rotor in the hollow cup motor has no iron core, small inertia, excellent functionality and a wide range of applications. In addition, in the research and development of coil winding equipment, the saddle-shaped coil arrangement is regular, and the utilization efficiency of magnets is high.

Compared with the old traditional motor with an iron core, the energy conversion efficiency is significantly higher than the latter, and the reaction speed will be much faster, and the hollow cup motor has high efficiency, fast response speed and stable performance. Because the hollow cup motor has no lag, additional electromagnetic interference is low, very high motor speed can be achieved, and the speed setting is sensitive at high speed, so it has relatively stable and stable performance. In addition, the energy density of the hollow cup motor is much greater than that of other motors, and the weight will be much less than that of an iron core motor with the same power.

Now according to the forming method of the coil, in the hollow cup motor coil, its production technology can be roughly divided into two process routes: winding production technology and one molding production technology.

Compared with the two methods, the first winding production technology is more complex, and the efficiency of winding the coil is relatively low. In order to improve the winding efficiency of coil production, the winding machine can be added to the production process of one molding. According to the hollow cup coil shape and winding method, the common hollow cup winding method can be divided into three kinds of parallel straight winding, saddle winding and oblique winding. The first parallel straight winding is generally used for hollow cup motor winding with relatively few turns. The last two are the two coil winding processes commonly used by the relatively advanced hollow cup motor manufacturers abroad.

REPOSAL® has successfully released a radiofrequency ablation catheter winding machine

Radiofrequency ablation has ablation and cutting functions, and the main therapeutic mechanism is thermal effect. Radio frequency refers to radio frequency, frequency up to 150,000 times per second of high frequency vibration, but it does not belong to the division of bands in radio communication.

The coiling process is completed by continuous test and optimization of the coiling machine.

The working flow of this winding machine is as follows:

1. The active wire feeding device of the radiofrequency ablation catheter winding machine ensures that the wires are constantly connected and not tied.

2. Double fold section A measurement line.

3. Manual folding head.

4. Manually fix the thread head (Two schemes are tentatively proposed for fixing the thread head)

4.1 Fix the starting position with glue. The fixture locks the PEEK tube.

4.2 Kangtong wire is hung on the feature of steel pipe. Glue to fix the ends after wrapping.)

5. Press the start button of the radiofrequency ablation catheter winding machine to wrap.

6.(During the winding process of the radiofrequency ablation catheter winding machine, both AB and AB segments have adjustable tension)

7. Wrap the jump grid to the specified position (the specific hop length can be set, and the rotation Angle can be set.

8. After the radiofrequency ablation catheter winding machine is finished, the feeder stops at the end and maintains tension.

9. Fix the end of the line by manual dispensing

10. Both ends of the radiofrequency ablation catheter winding machine are coaxial, and the rotation direction is synchronized.

11. Adjustable pre-drawing force is required at both ends of the locking shaft core.

U-shaped core winding machine

Transformer coil winding machine

Stable, high-speed and safe U-shaped core coil winding machine

The U-shaped coil winding machine is suitable for the winding of the bottom edge of the U-shaped core.Usually, the center of the U-shaped core is difficult to coincide with the rotation axis of the winding machine, resulting in a large vibration of the winding machine. , Affecting efficiency.

This type of winding machine developed by our company does not rotate the U-shaped iron core, only reciprocates, and rotates around the product to reduce vibration and improve efficiency.

With the optimized clamping method, it only takes 2 seconds to complete the clamping.

Therefore, the rotating parts of this type of machine have a large diameter and a high speed.There are similar machines on the market, and the larger ones do not have a protective cover. Safety accidents often occur.This machine of the company has a protective cover design.

REPOSAL Winding Machine® Released Tandem flat-wound winding machine

REPOSAL Winding Machine® Released Tandem flat-wound winding machine

REPOSAL® releases double-wound thick wire diameter air core coil winding machine

Suzhou REPOSAL® Electronic Machinery Equipment Co., Ltd. released the sp-s112hb double-wound thick-wire air-core coil winding machine model-this model is mainly for the air-core coil with a large enameled wire diameter, and the winding speed is fast and consistent. Good performance, through the optimization of the control system and machinery, during the winding process of the larger enameled wire diameter air-core coil, it provides customers with a competitive solution for wire end fixation, tension control, winding accuracy, and demolding speed.

Suzhou REPOSAL® Electronic Machinery Equipment Co., Ltd. released the sp-s112hb double-wound thick-wire air-core coil winding machine model-this model is mainly for the air-core coil with a large enameled wire diameter, and the winding speed is fast and consistent. Good performance, through the optimization of the control system and machinery, during the winding process of the larger enameled wire diameter air-core coil, it provides customers with a competitive solution for wire end fixation, tension control, winding accuracy, and demolding speed.

REPOSAL Winding Machine® Released high-speed precision synchronous winding machine

Suzhou REPOSA Electronic Machinery Equipment Co., Ltd. releases high-speed precision synchronous winding machine

REPOSAL® successfully developed an ultra-precision flow tube metering heating wire winding machine

On August 6, the first ultra-precision flow tube metering heating wire winding machine independently developed by Suzhou REPOSAL® Electronic Mechanical Equipment Co., Ltd. successfully completed the test, and the performance of each index reached the level of the industry in advanced foreign countries.

At present, the ultra-precision flow tube, a metal tube with a diameter of 0.4mm, a wall thickness of 0.1mm, an inner diameter of 0.2mm, and a special metal wire of 0.03mm are wound. There are single-layer winding, double-layer winding, and double-layer butt-joining winding. Flow tube is required There is no deformation at both ends and the metal wires are arranged neatly. This process technology has been monopolized by foreign companies for a long time, and the price is high, which severely restricts the research and achievement of ultra-precision flow meters in China.

Ultra-precision flow tube metering heating wire winding machine is an important symbol of independent innovation ability. The research of this equipment has broken through many key technologies of precision winding technology and optimized the process and mechanical structure. In the next step, Suzhou REPOSAL Electronic Machinery Equipment Co., Ltd. will further optimize the design and production process, reduce the cost of the whole machine, make it better to market, and accelerate the application and industrialization of localized precision winding machines.

REPOSAL winding machine continuous innovation to consolidate brand value

Suzhou REPOSAL Electronic Mechanical Equipment Co., Ltd. is a technology enterprise specializing in R&D and production of winding equipment. For many years, it has insisted on maintaining innovation and researching and developing products with independent intellectual property rights.

For quite a long time, my country's winding machine manufacturing industry generally has the problems of low technology, small scale, free and scattered production, and insufficient technological innovation of most enterprises. Compared with related industries abroad, my country currently has fewer types of winding machines and supporting equipment. The control technology used is relatively backward, and its accuracy and performance are not as good as those of their European and American counterparts. Moreover, the product has low production capacity and poor stability.

In the face of technical gaps, Suzhou REPOSAL made a detailed market research and took the entire series of precision winding machines and Roche coil winding machines as breakthrough points.It valued cooperation with user companies and not only carefully understood the existing process requirements of customers. And through the company's accumulated technical database for many years, on the premise of no or little increase in costs, it actively provides new ideas and new solutions for customer process upgrades.In a specific single implementation case, this approach has undoubtedly aggravated us The execution cost of the company has reduced the company's profits, but this idea has been implemented and verified for a long time.In fact, our customers have tapped the potential of the coil winding process through our winding machine equipment and become our long-term cooperative customers. We have also accumulated more technical data for our research and development direction and solutions through proactive improvement of individual cases, so as to achieve continuous innovation.