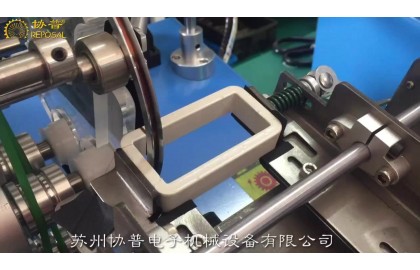

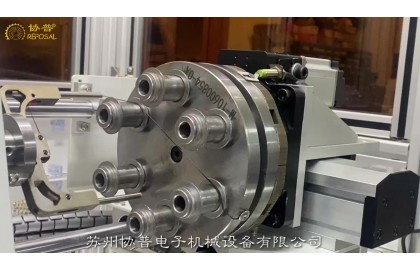

U-shaped core winding machine

he U-shaped coil winding machine is suitable for the winding of the bottom edge of the U-shaped core.Usually, the center of the U-shaped core is difficult to coincide with the rotation axis of the winding machine, resulting in a large vibration of the winding machine. , Affecting efficiency.

This type of winding machine developed by our company does not rotate the U-shaped iron core, only reciprocates, and rotates around the product to reduce vibration and improve efficiency.

With the optimized clamping method, it only takes 2 seconds to complete the clamping.

Therefore, the rotating part of this type of machine has a large diameter and a high speed.There are similar machines on the market, and the larger one does not have a protective cover. Security accidents often occur.This machine of the company has a protective cover design.

Related Post

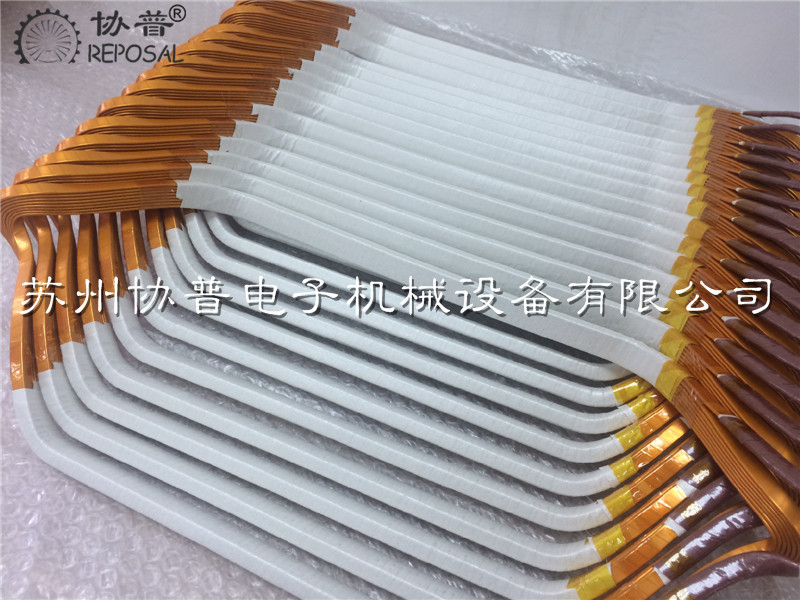

REPOSAL® releases layer-wound high-voltage package full-automatic interlayer insulation winding machine

REPOSAL® releases layer-wound high-voltage package full-automatic interlayer insulation winding machine

Suzhou Xiepu Electronic Machinery Equipment Co., Ltd. successfully released the SP-D102M7 model of layer-wound high-voltage package automatic interlayer insulation winding machine-this model greatly improves the winding efficiency of layer-wound high-voltage package coils, and the coil is consistent Sex. The REPOSAL® winding machine reduces the winding cost of the layer-wound high-voltage package. In the new model, it has added a compact insulation belt automatic cutting mechanism, and high-quality solutions such as dynamic balance performance after multiple skeletons are wound.

Enclosed rectangular transformer winding machine-thin wire reciprocating

Enclosed rectangular transformer coil with a thin diameter of 0.12mm, which requires fast winding speed and convenient product loading and unloading.

The advantages of Type R transformer and the status quo of type R transformer winding machine

Although R type transformer is widely used, but in fact the production of manufacturers are not many, the reason is limited by the R-Core transformer winding machine, so far, there are many R-Core transformer winding machine is the principle of manual wiring, so its winding production efficiency is relatively low, Up to now, many factories are using manual winding in the winding of R-shaped transformers.

In response to this situation, we have launched an automatic R-Core transformer winding machine with high precision, complete functions, easy to use, stable and cost advantages, which has been widely recognized by customers since its launch. Our R type transformer winders have the following features:

1. R-Core transformer winding machine special controller, high precision, stable and reliable, easy to operate, computer (single chip microcomputer) control, full key operation, working state digital display.

2. 1000 sets of process data can be stored and called, and it has the function of button and foot start and stop, and the speed can be increased and decreased during the winding process.

3. Handle built-in start-stop switch, which can improve efficiency, especially convenient for debugging.

4. The configuration of a first-line brand laser amplifier, long life, high precision, low failure rate, stable and reliable counting, laser amplifier installation structure optimization, can be far away from the coil skeleton end face accurate and reliable detection of the number of turns, fundamentally solve the probe collision roller and skeleton movement brought about by the count unreliable problem.

5. R-Core transformer winding machine press wheel adopts step bearing design, which can effectively control the axial movement of the skeleton in the rotation process.

6, the controller has complete functions: abnormal alarm function, such as overload, reverse wiring direction, speeding and so on.

7. Linear acceleration and deceleration function can be set at the beginning and end of winding, which can eliminate the sudden acceleration and deceleration effect and avoid disorderly or broken lines.

Transformer winding machine

Transformer winding machine:

Similar to transformers, current transformers also work according to the principle of electromagnetic induction. The transformer transforms voltage and the current transformer transforms current. The current transformer is connected to the winding of the measured current (the number of turns is N1), called the primary winding (or primary winding, primary winding); the winding connected to the measuring instrument (the number of turns is N2) is called the secondary winding (or secondary side) Winding, secondary winding).

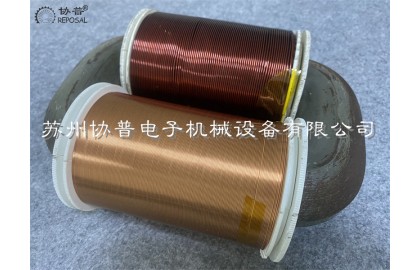

This ring current transformer winding machine is generally used to wind small size current transformers. The characteristics of small size current transformers are generally wire diameter of enameled wire between 0.11-0.19mm, and the number of turns is large.

It requires accurate turns and fast winding speed.

REPOSAL this machine is fast and stable, and the speed reaches 1400RPM. Because it is stable, it can realize the operation of multiple ring current transformer winding machines by one person.

Transformer winding crepe paper | Transformer winding crepe paper | Transformer winding crepe paper

Transformer insulating crepe paper has good mechanical strength, high withstand voltage strength, wrinkles on the surface, and a certain degree of toughness. Moreover, it is easy to cut. After the transformer is wound and formed, it still maintains a certain strength in the oil immersion of the rear tooling. This feature can very well protect the enameled wire of the transformer from being squeezed and broken, that is, it meets the insulation requirements. It also meets the mechanical performance requirements.

Therefore, it is widely used for transformer insulation. Generally used in transformers, but less used in transformers, because the core structure of transformers is annular, because the surface of the insulating crepe paper has wrinkles and friction is large, so the annular wrapping machine is used. Winding is more difficult, so in general, if crepe paper is required for the transformer coil, manual winding is used. We have successfully overcome this problem by improving the details.

REPOSAL® releases Automatic winding machine

Suzhou REPOSAL® Electronic Machinery Equipment Co., Ltd. released: automatic induction coil winding machine.

This model is mainly used for the winding of rod-shaped inductors. During the winding process of this winding machine, the rod-shaped inductor realizes unattended full automation. Its winding speed is fast, inductance consistency is good, and debugging Convenient and easy to maintain, it provides a competitive solution for the winding process of rod-shaped inductors for the cooperative customers of REPOSAL®

Micro toroidal coil winding

Before winding:

Outer diameter 7.5mm

Inner diameter 4mm

Height 2.3mm

Enameled wire diameter: 0.17mm

80 laps.

Process requirements of traction motor winding machine

Traction motors are mainly used for railway mainline electric locomotives, industrial and mining electric locomotives, electric drive diesel locomotives and various electric vehicles (such as battery cars, urban trams, subway electric vehicles).

The constraints of the coil during the winding process of the winding machine mainly come from two aspects: design requirements and craftsmanship. The specific manifestations are:

The structural design of coils and windings must not only meet the requirements of electrical performance and temperature rise limit, but also the applicability of existing winding machines, the economical and reasonable use of electromagnetic wires and insulating materials, simple structure and convenient manufacturing, that is, it should have Good manufacturability. In order to achieve better manufacturability and reliability, there are some control points that must be considered in the early stage. For this type of problem, REPOSAL®winding machine shares some content with you.

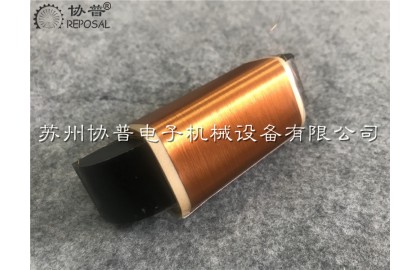

Special miniature permanent magnet trip coil winding machine

As shown in the figure, this miniature permanent magnet trip coil is widely used by ABB, EATON Muller compact circuit breaker, and has a compact structure. On a tiny metal structure bracket, a suction coil is wound that is closed to the metal structure. It seems simple, but its design technology is very strong. Therefore, it has been the industry enterprises in this kind of products to achieve the domestic industry barriers.

With the attitude of professional focus and the trust of advanced customers in the circuit breaker industry in Mongolia, REPOSAL® winding machine has gone all out to successfully reverse crack this technological process and help customers of REPOSAL® winding machine to make this product domestically smoothly.

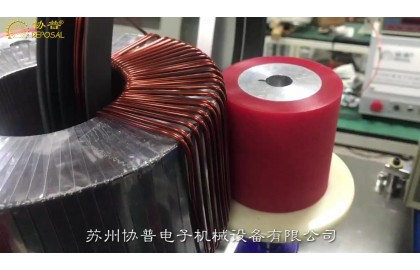

Toroidal transformer winding machine

Toroidal transformer winding machine

The company has the advantages of R&D and production of electronic transformers and transformers in the whole factory equipment. Different from many assembly manufacturers in the industry, we have accumulated many years of experience in R&D and production in the winding machine industry and developed a new generation of toroidal coil series winding The equipment is widely used in the manufacturing industries of toroidal transformers, transformers, voltage regulators, inductance coils, etc., and has been well received by the industry; Suzhou REPOSL will continue to understand user needs and strengthen technical research and development and after-sales service levels, and provide customers with more professional and high-quality products and service.

Technical features of our toroidal transformer winding machine:

Using CNC digital intelligent program controller, stable work, simple operation, with a number of industry-first advanced and practical functions.

The core components such as the thread storage ring and the thread belt are made of high-quality steel through multiple processes, which are durable and not deformed.

It adopts advanced control circuit and has fault alarm function. The function switches are all controlled by two lines, which is easy to maintain and replace.

The operating speed is set separately in the storage and winding state, which can automatically realize the fast storage and low-speed winding operation. The automatic operation function can also be used in the taping machine mode. The operation is simple and the use efficiency is high.

When processing multi-winding products, multiple storage and multiple winding procedures can be preset, which is suitable for products with multiple windings but different wire diameters/numbers of turns, or products with insufficient wire storage in a single time, eliminating repeated installation Clamping and manual operation improve production efficiency.

Multiple sets of wire density can be preset, and the device can automatically change the preset wire density when winding. When processing multi-winding products, each winding with different turns can be evenly arranged at a preset angle.

Double frequency conversion proportional drive, automatic operation or pedal speed regulation can be selected.

The speed can be adjusted steplessly, and the appropriate winding speed can be set according to the process requirements of different products.

Features:

The gear winding machine has the characteristics of large winding torque, high opening size of the gear ring roof ring, a large amount of wire storage and a large range of suitable winding diameters. It is the most versatile

Winding model; suitable for products with thick winding diameters, neat wiring requirements and multiple parallel windings, such as small toroidal transformer secondary windings, high-power 驽

Technical features of our toroidal transformer winding machine:

Using CNC digital intelligent program controller, stable work, simple operation, with a number of industry-first advanced and practical functions.

The core components such as the thread storage ring and the thread belt are made of high-quality steel through multiple processes, which are durable and not deformed.

It adopts advanced control circuit and has fault alarm function. The function switches are all controlled by two lines, which is easy to maintain and replace.

The operating speed is set separately in the storage and winding state, which can automatically realize the fast storage and low-speed winding operation. The automatic operation function can also be used in the taping machine mode. The operation is simple and the use efficiency is high.

When processing multi-winding products, multiple storage and multiple winding procedures can be preset, which is suitable for products with multiple windings but different wire diameters/numbers of turns, or products with insufficient wire storage in a single time, eliminating repeated installation Clamping and manual operation improve production efficiency.

Multiple sets of wire density can be preset, and the device can automatically change the preset wire density when winding. When processing multi-winding products, each winding with different turns can be evenly arranged at a preset angle.

Double frequency conversion proportional drive, automatic operation or pedal speed regulation can be selected.

The speed can be adjusted steplessly, and the appropriate winding speed can be set according to the process requirements of different products.

Features:

The gear winding machine has the characteristics of large winding torque, high opening size of the gear ring roof ring, a large amount of wire storage and a large range of suitable winding diameters. It is the most versatile

Winding model; suitable for products with thick winding diameters, neat wiring requirements and multiple parallel windings, such as small toroidal transformer secondary windings, high-power 驽

Outer diameter: 193mm

Inner diameter: 95mm

Height: 90mm

Enameled wire diameter: 2.5mmX370

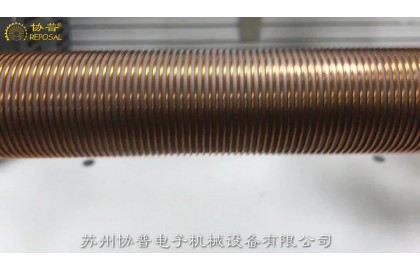

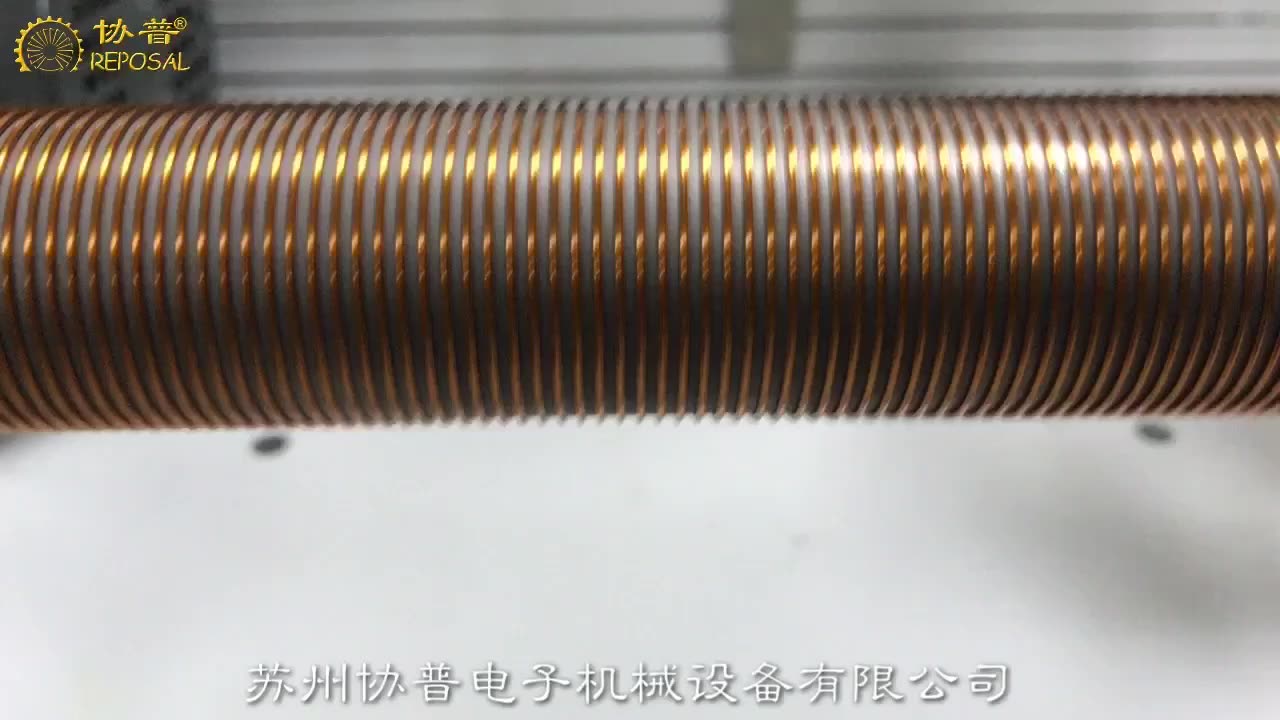

Introduction of winding method of electric heating tube

This type of winding machine of Xiepu has a stroke of 1.5 meters, adopts pneumatic quick assembly and quick disassembly, convenient operation, mature and stable structure, easy maintenance, easy operation of the system, complete functions, and strong expandability.

At present, according to customer requirements, a heating coil with a stroke of up to 1.5 meters is wound on this machine. Because the equipment is structured in place, the winding has a satisfactory effect. The customer currently plans to add mica tape winding function on this basis.

Solenoid valve winding machine|Solenoid valve coil precision winding machine|Precision winding machine

Solenoid valve winding machine|Solenoid valve coil precision winding machine|Precision winding machine:

For precision electromagnetic coils, there are usually many turns, which require neat arrangement, and the process design is also divided into two types with and without skeleton.

For frameless coils, steel molds are required to form.Relatively speaking, the precision of steel winding molds is better controlled.

Under the existing solenoid valve winding machine processing technology, it is not difficult to achieve a size of 0.01mm on both sides of the steel winding mold, and the parallelism on both sides is 0.01

mm is also not difficult. However, if there is no wire frame mold steel wire winding mold, there will be two new problems, one is forming, the winding is completed

After the final removal, there is no skeleton.To prevent the coil from being scattered, it is necessary to use an alcohol fuse or a hot fuse. These two materials

Compared with the ordinary wire, the cost is not small. The second problem is demolding, a thicker one, and more windings

It's quite laborious to remove the coil from a steel mold, it's not like a coil with a small coin, and

What's more, this winding process itself has viscous materials that are melted or hot melted.

So people also use the second solenoid valve winding machine process, a precision electromagnetic coil with a skeleton.Similarly, this is not a very good process route.

The skeleton is formed by an injection mold, and there are inevitably some problems with injection products, such as deformation, shrinkage, dimensional consistency, etc.

However, the advantages of this solenoid valve winding machine are also obvious, that is, it is easy to demold and form. It is only because of the poor consistency of the size of the skeleton.

Higher requirements are put forward, the key point is that wire, skeleton structure, skeleton mold, winding tooling, winding machine, every link

Will affect the quality of the winding, in this case, according to our own advantages, we provide a complete service according to customer needs

Including skeleton design, mold structure design, tooling design, and winding machine. In the past successful cooperation, this way of service Gret advantages.

Research and development background and characteristics of precision current transformer winding machine

Research and development background and characteristics of precision current transformer winding machine

The precision of coil in current transformer is very important, because it directly affects the accuracy of current measurement and the reliable operation of power system. The specific importance of coil accuracy is reflected in the following aspects.

Electrical energy metering: In a power system, accurate measurement of current is the key to calculating energy consumption. If the coil in the current transformer is not accurate, it will lead to an error in the measurement of electrical energy, which can lead to a miscalculation of energy costs, with possible financial implications for both the utility and the consumer.

Fault detection: The current transformer is used to monitor the current level to detect abnormal conditions in the power system, such as short circuit and overload. If the accuracy of the coil is not high, it may lead to false positives or neglect of potential faults, which affects the reliability of the power system.

Overcurrent protection: Current transformers play a key role in overcurrent protection devices, detecting overcurrent events and triggering circuit breakers or other protective devices. The accuracy of the coil directly affects whether the overcurrent can be accurately detected to ensure the safety of the power system.

Load management: The load management of a power system requires accurate measurement of current in order to make reasonable load distribution and adjustment. If the precision of the coil is not high, it may lead to unbalanced load distribution, affecting the efficiency and stability of the power system.

Automated control: In modern power systems, automated control systems rely on accurate current measurement data for real-time adjustment and control. The precision of the coil is critical to the response speed and performance of the system.

Waveform analysis: Current transformers are also used for power quality analysis, including harmonic analysis. The precision of the coil determines the accurate analysis of the current waveform, which helps to solve the power quality problem.

What are the application scope and types of winding machines?

Winding machine: As the name implies, a winding machine is a machine that winds a linear object onto a specific workpiece.

The scope of application of the winding machine:

Most electrical products need to use enameled copper wire (referred to as enameled wire) to be wound into inductance coils, which requires a winding machine.

For example: various motors, fluorescent lamp ballasts, transformers of various sizes, televisions. The mid-periphery and inductive coils used in the radio, the line output transformer (high-voltage package), the high-voltage coil on the electronic igniter, the mosquito killer, the loudspeaker, the earphone, the voice coil of the microphone, the various electric welding machines, etc. can not be cited one by one. All coils need to be wound with a winding machine.

In the textile industry, cotton yarns, man-made fiber yarns, etc. are used to wind all kinds of yarn balls and frays suitable for textile machines. These require a winding machine to wind.

Type of winding machine:

Commonly used wire winding machines are mostly enameled copper wire (winding inductance coils for electronic and electrical products), textile wire (winding yarn frays and coils for textile machines), and winding electric heating appliances. Electric heating wires and solder wires, wires, cables, etc.

There are many types of winding machines, which can be classified into general-purpose and special-purpose types according to their uses;

Instructions for use of side-sliding transformer winding machine

Instructions for use of side-sliding transformer winding machine

Clamp Ammeter Coil Winding Machine|Clamp Meter Coil Winding Machine|Semicircle Transformer Winding Machine

Clamp Ammeter Coil Winding Machine|Clamp Meter Coil Winding Machine|Semicircle Transformer Winding Machine

The semi-circular coil winding machine developed by Suzhou Xiepu Electronic Mechanical Equipment Co., Ltd. is suitable for the winding of semi-circular skeleton, iron core and magnetic core coil. Its running operation, high speed, safety cover is convenient and practical. Fast and repeatable positioning accuracy. Applicable products are: semi-circular transformer coil, semi-circular heating wire coil, clamp meter coil, etc.

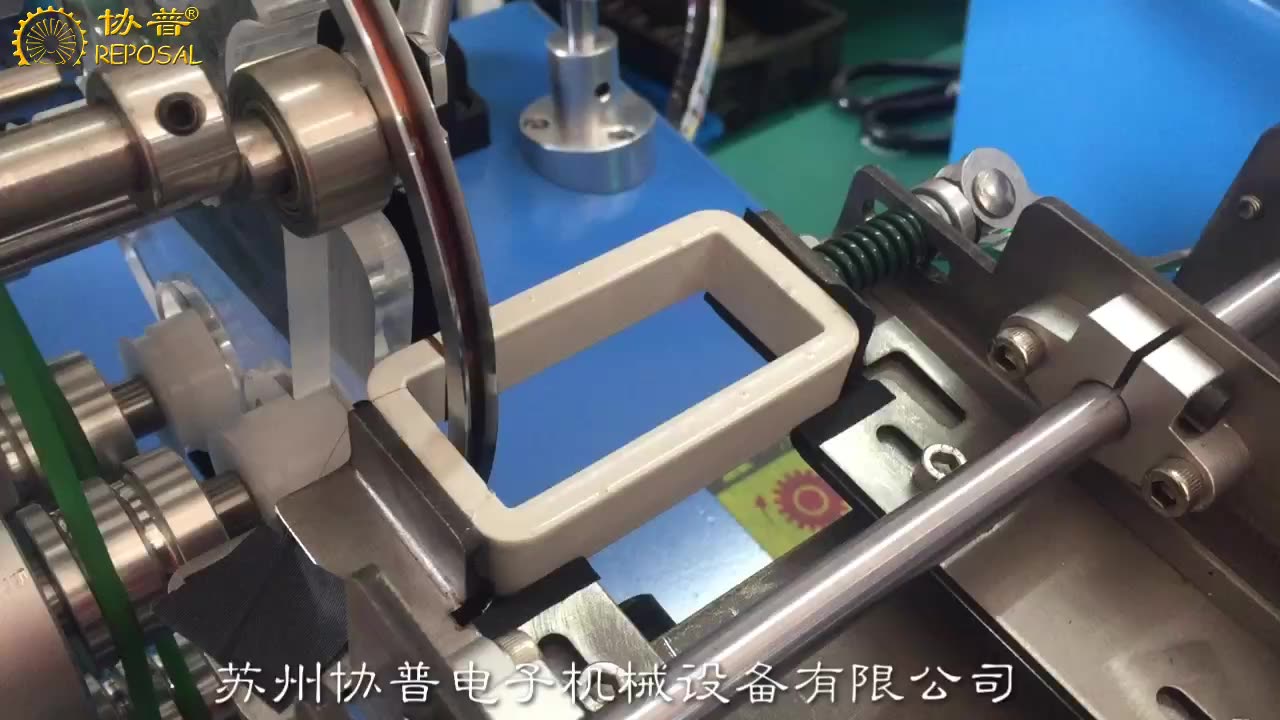

Flexible Driveline Coupling special winding machine

Flexible Driveline Coupling special winding machine

The automobile drive shaft is the part connecting the gearbox and the drive axle. It is a high speed rotating body, and the drive shaft connecting disk is the part balancing the action of the drive shaft.

The structure of the connecting disk of the drive shaft is shown in the figure below:

Existing shaft connection plate is made up of rubber vulcanization six sets of steel, its structural strength mainly provided by the rubber, in order to increase the structural strength, the manufacturer will before die casting vulcanized rubber, between the six sets of steel nylon line, its technology and processing technology is very similar to synchronous belt, between the six sets of steel round the multi-layer nylon thread, die-casting vulcanized rubber, It's a good reinforcement. Such as Mercedes-Benz, Ford have adopted this process.