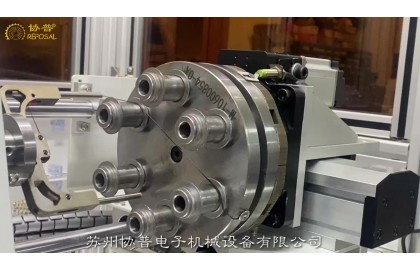

REPOSAL® winding machine releases special winding machine for frequency divider inductors

REPOSAL® winding machine releases special winding machine for frequency divider inductors

In daily life, have you ever noticed more than one horn on your car? And more expensive cars have more horns. According to normal people's thinking, the car as long as there is a horn can emit sound signals on the line, more horn is why? The reason is very simple, for example, the turn signal and the warning horn are completely different, the sound frequency is different, and the sound range of the speakers used for high and low is naturally different. A single speaker cannot play a full frequency sound, and a sound may require a combination of multiple channels of sound to achieve a clear cue.

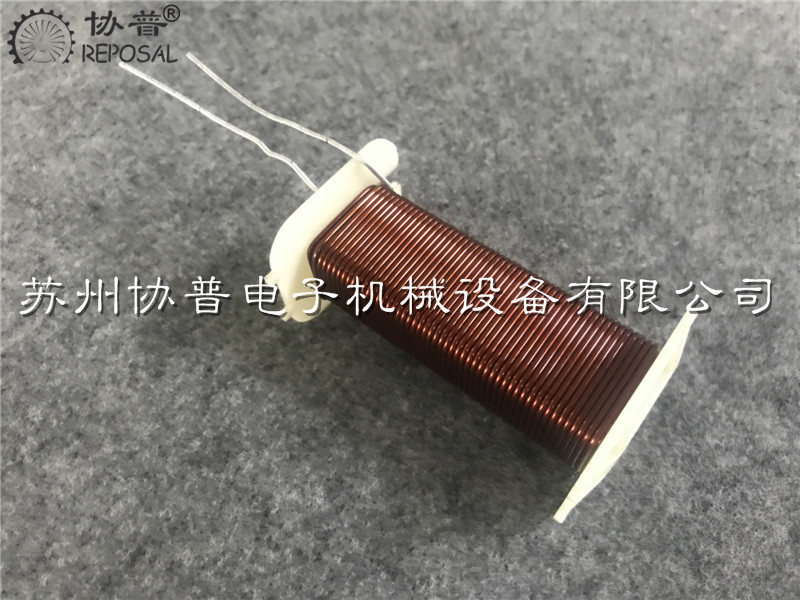

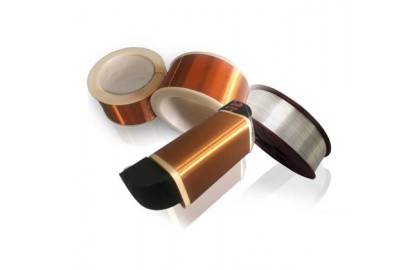

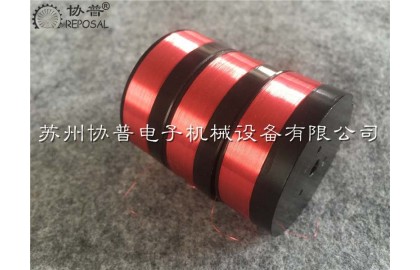

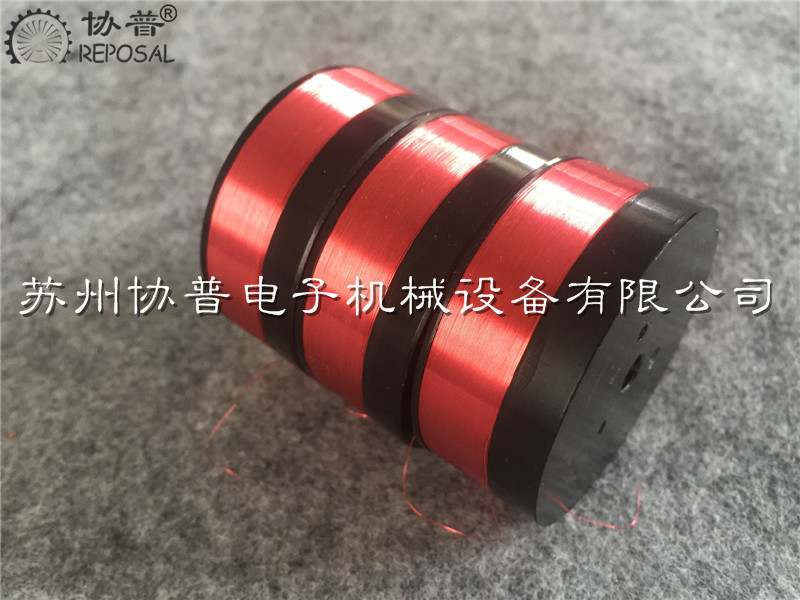

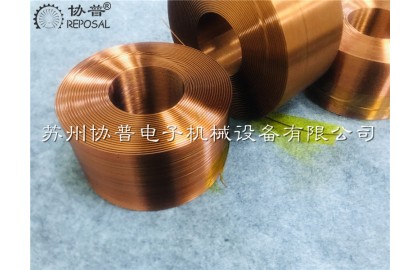

Therefore, in order to make each speaker emit audio suitable for it, it is necessary to use a tool such as a frequency divider. In simple words, the frequency divider is a filter circuit composed of a capacitor and a frequency divider inductor coil wound by the frequency divider winding machine. The capacitor filters the low frequency to the tweeter, and the frequency divider inductor is wound by the frequency divider winding machine to filter the high bottom to the low frequency to the woofer, so as to distinguish the sound signals in different frequency bands in a sound. It has different sound frequency channels, high frequency sound channels can only pass high frequency sound, middle and low frequency sound the same. After the sound is distinguished, the sound is amplified and played in the corresponding sound amplifier, and finally we can get the most accurate audio we want.

Frequency dividers are divided into two categories, one is a power divider, and the other is an electronic divider.

The power divider is set in the speaker, the power amplifier in the speaker first amplifies the sound power, and then the power divider divides it into three audio signals, high, middle and low, and finally sends it to different speakers for playback. The advantage of this power divider is that it is simple and convenient to connect and use, but its disadvantages are also obvious, that is, its power consumption is large and the parameter deviation value is large, the error of the sound frequency is large, and its error is related to the impedance of the speaker, so it is not convenient to adjust.